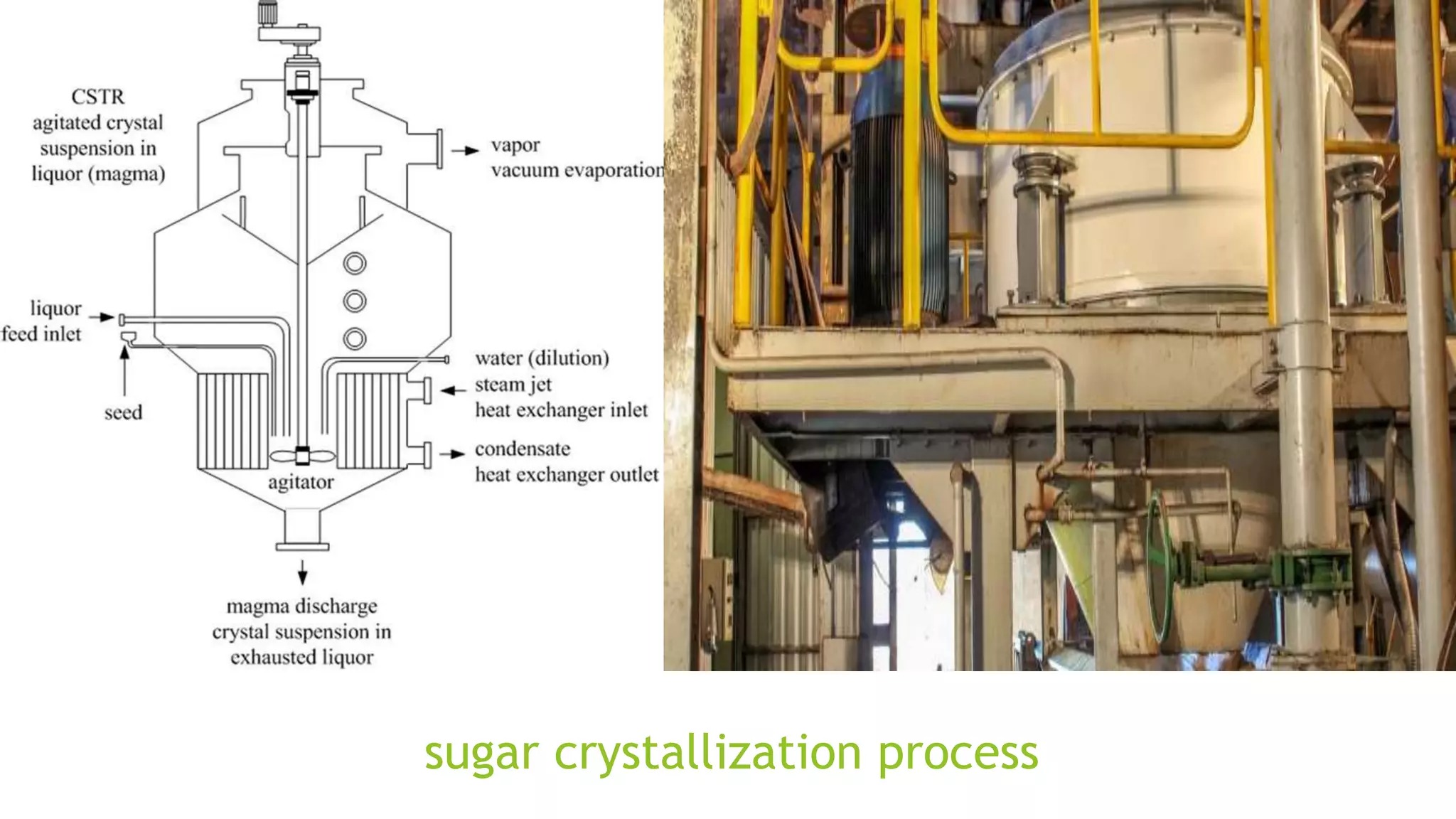

This document discusses sugarcane and sugar production. It begins with an introduction to sugarcane, describing that it is a grass cultivated in over 90 countries, with Brazil being the largest producer. It then covers the sources of sugar from sugarcane and sugar beets, the composition of sugarcane stalks, and factors that affect sugarcane quality. The document concludes with an overview of the sugar production process from sugarcane, including extraction, clarification, evaporation, crystallization, separation and drying to produce white crystalline sugar, as well as byproducts like bagasse and molasses.