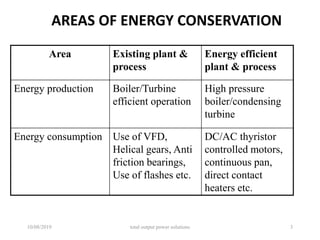

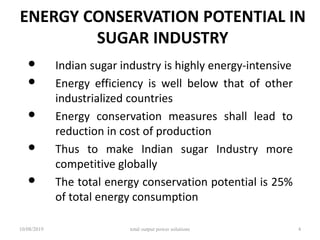

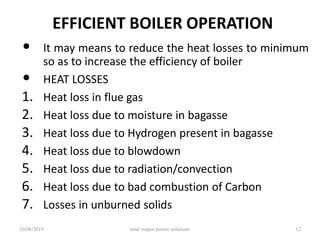

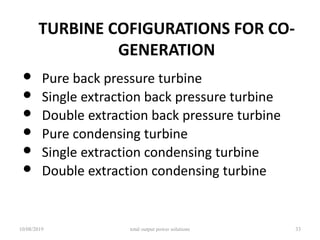

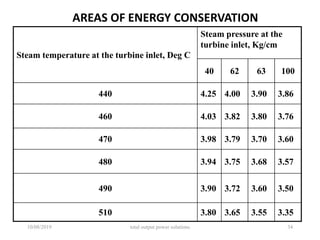

The document discusses energy conservation in the sugar industry, highlighting areas of high power consumption and potential efficiency improvements. It outlines methods for reducing steam and energy consumption, including the adoption of energy-efficient technologies and co-generation systems. The paper emphasizes the importance of energy conservation for enhancing competitiveness and sustainability in the sector.