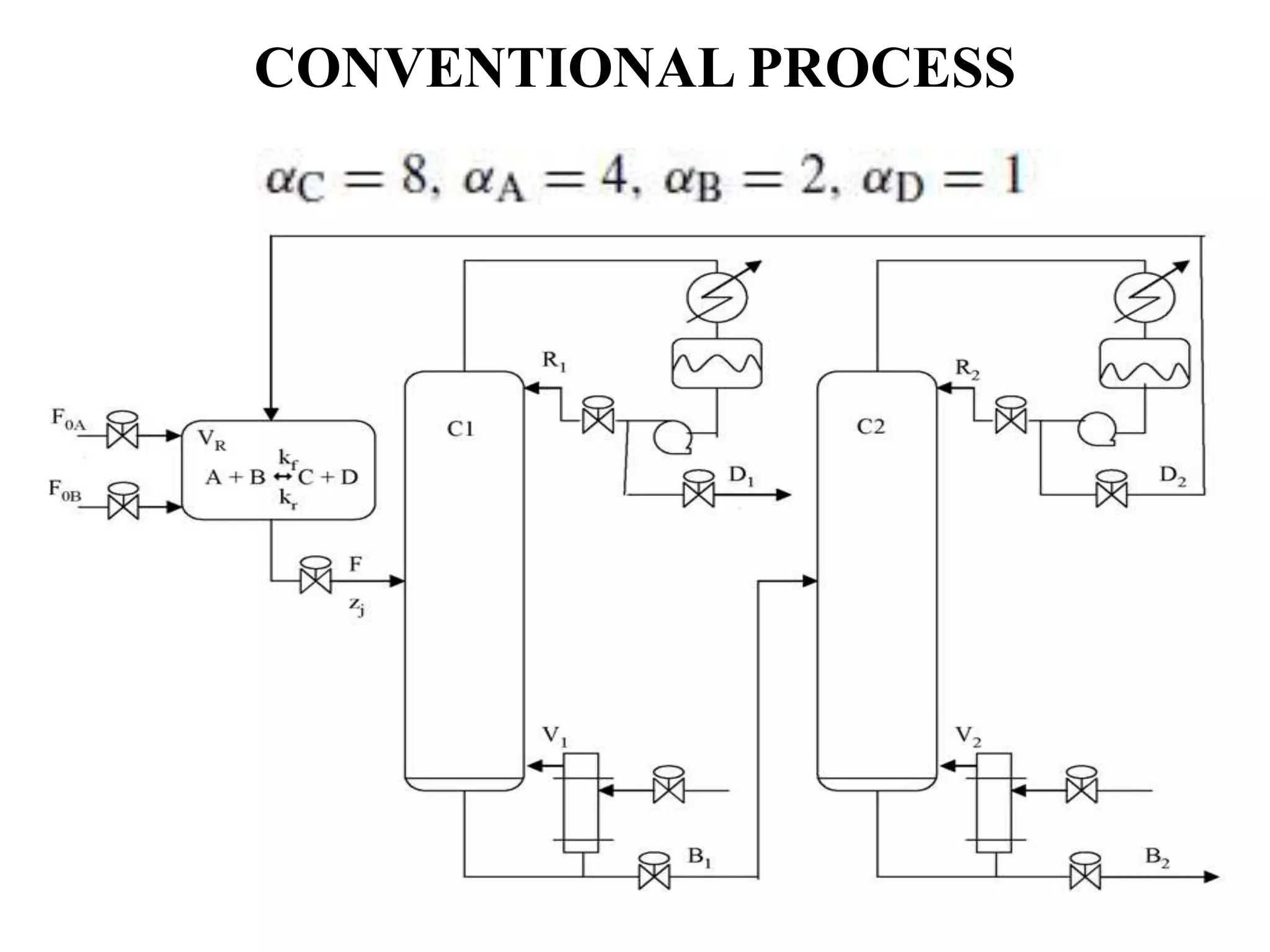

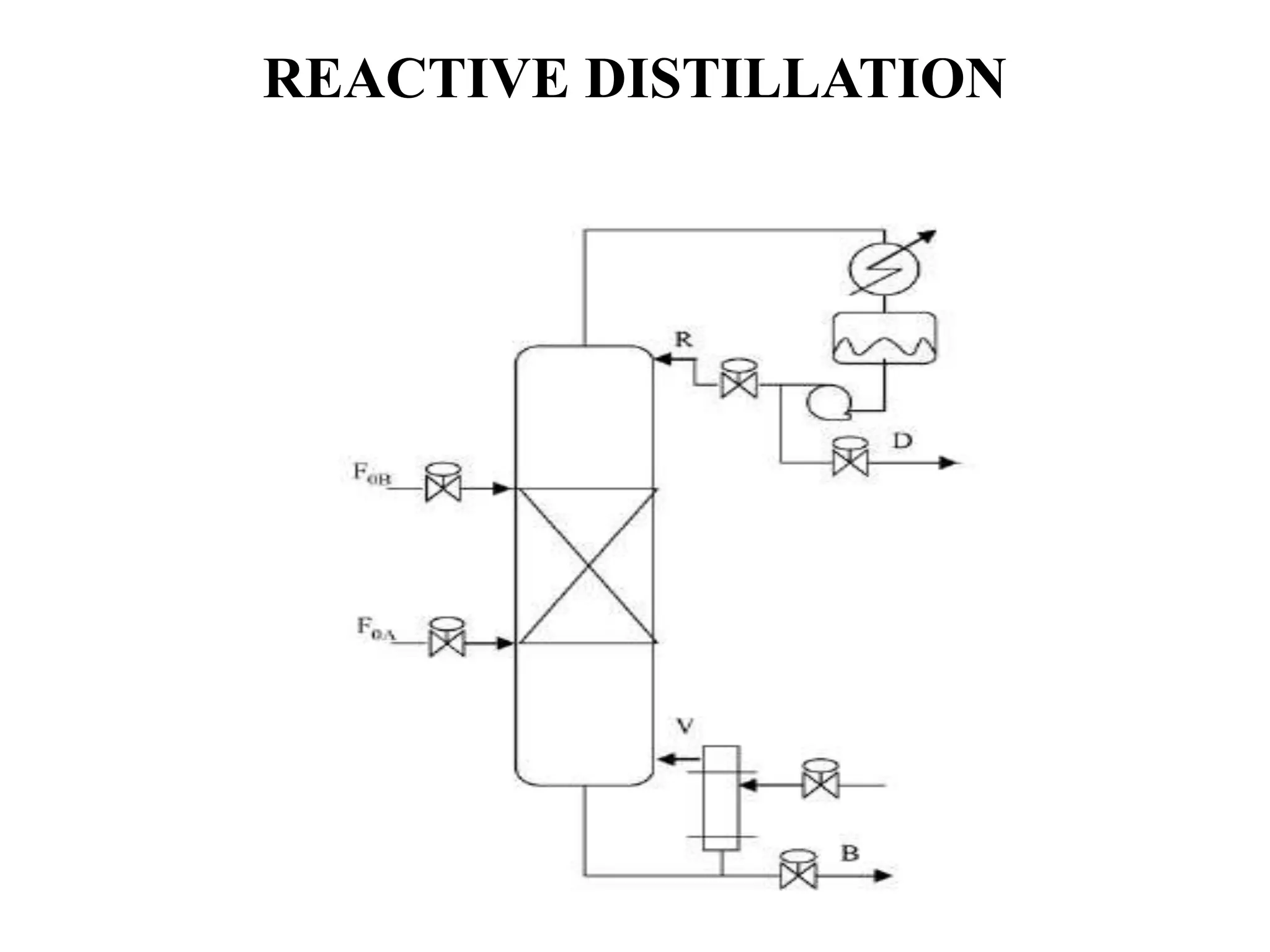

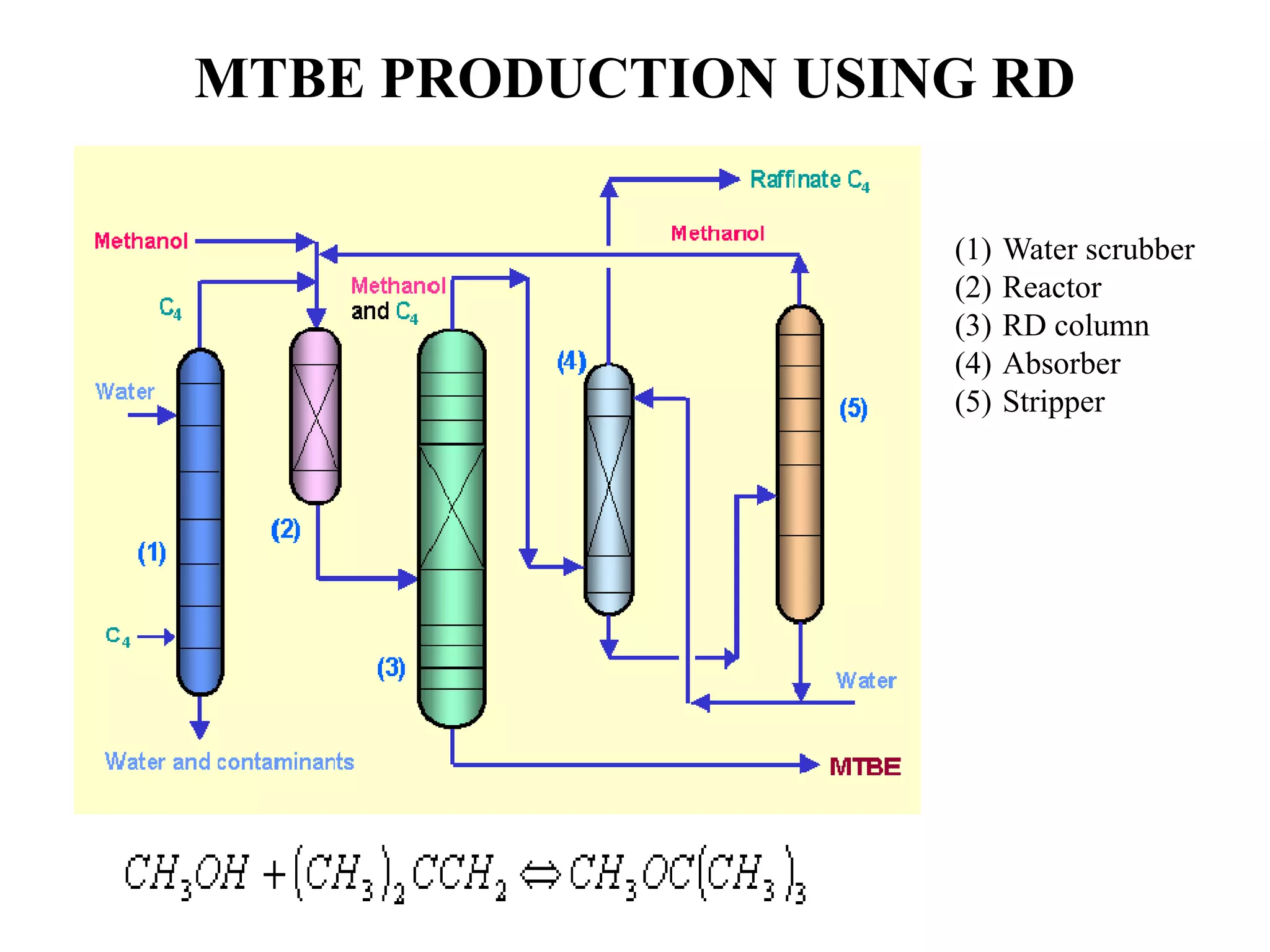

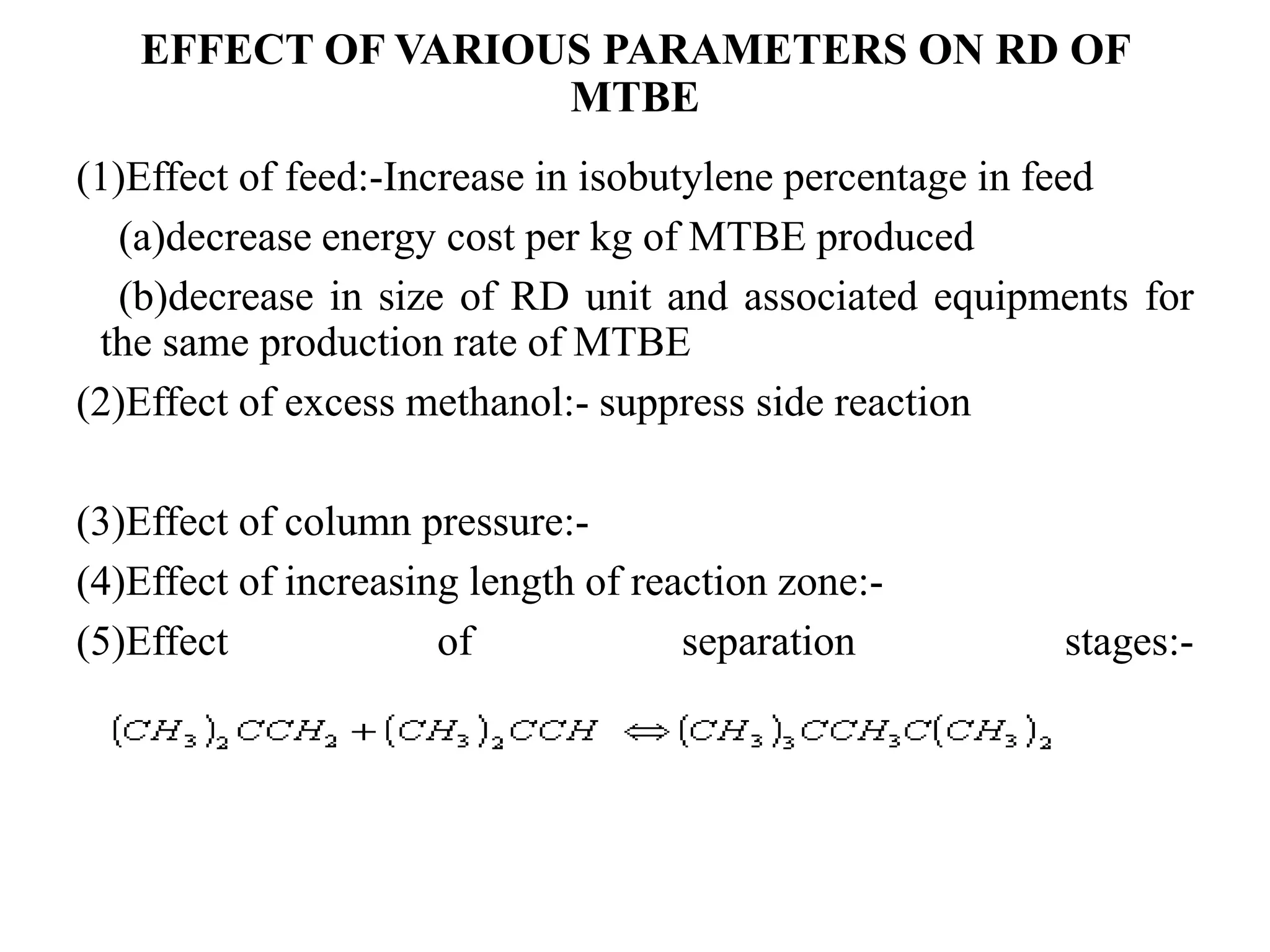

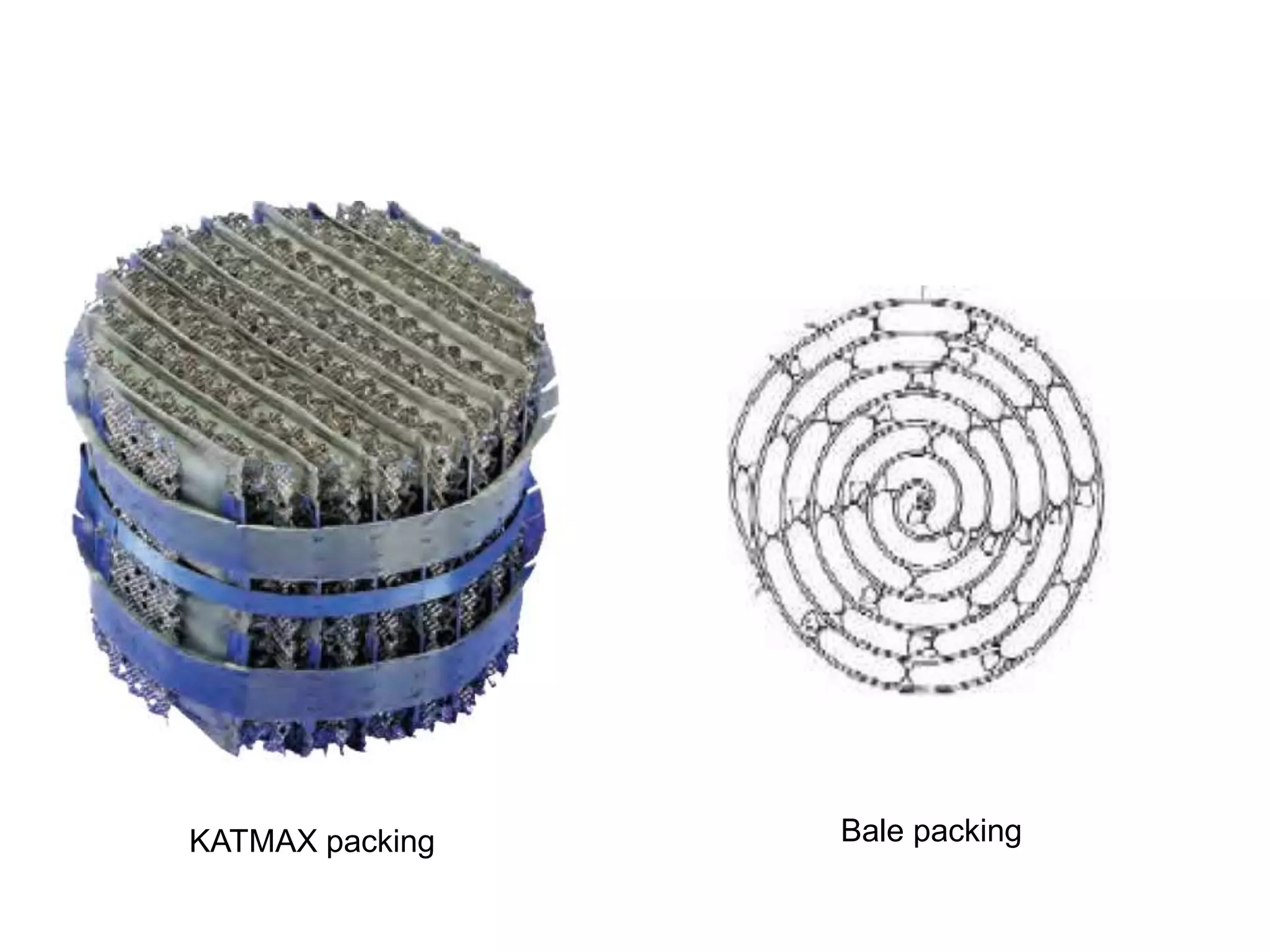

Reactive distillation, first used in the 1860s for ammonia recovery, has evolved through various applications, notably in MTBE production. The process leverages Le Chatelier’s law to optimize reaction conditions, affecting production variables like feed composition and column pressure. While it offers advantages such as improved selectivity and reduced costs, it also faces challenges related to volatility and residence time requirements.