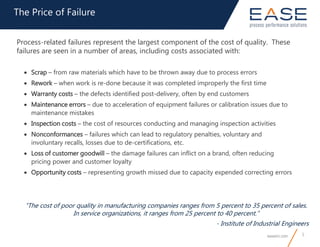

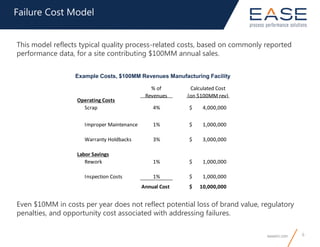

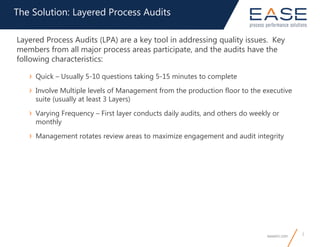

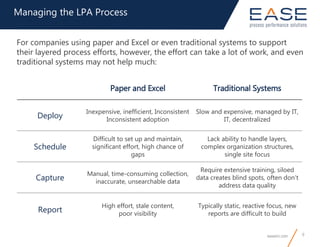

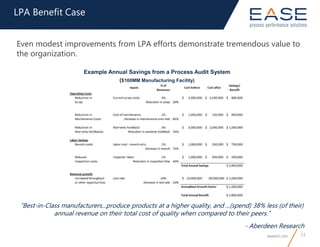

The document discusses the rising costs of quality failures across various industries, exemplified by significant financial losses faced by companies like GM, Takata, and Boeing due to process failures. It highlights the benefits of Layered Process Audits (LPA) as a proactive tool for improving quality management and reducing costs associated with defects and errors. The use of modern cloud-based LPA systems is presented as an effective solution for enhancing process audits, driving savings, and contributing directly to profits.