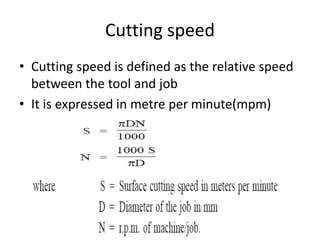

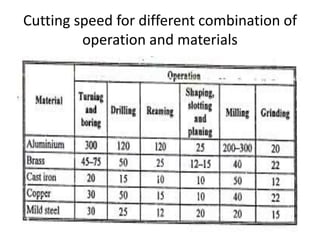

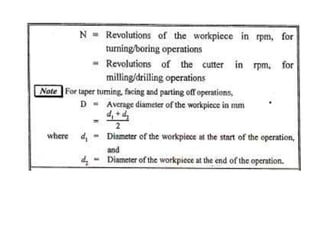

This document discusses process planning activities, including calculating important process parameters like cutting speed, feed rate, and depth of cut. It also covers selecting jigs and fixtures, the economics of process planning such as cost estimating and break even analysis, and determining the break even point through algebraic and graphical methods. Key factors that affect selecting the cutting speed for different machine operations and materials are also outlined.