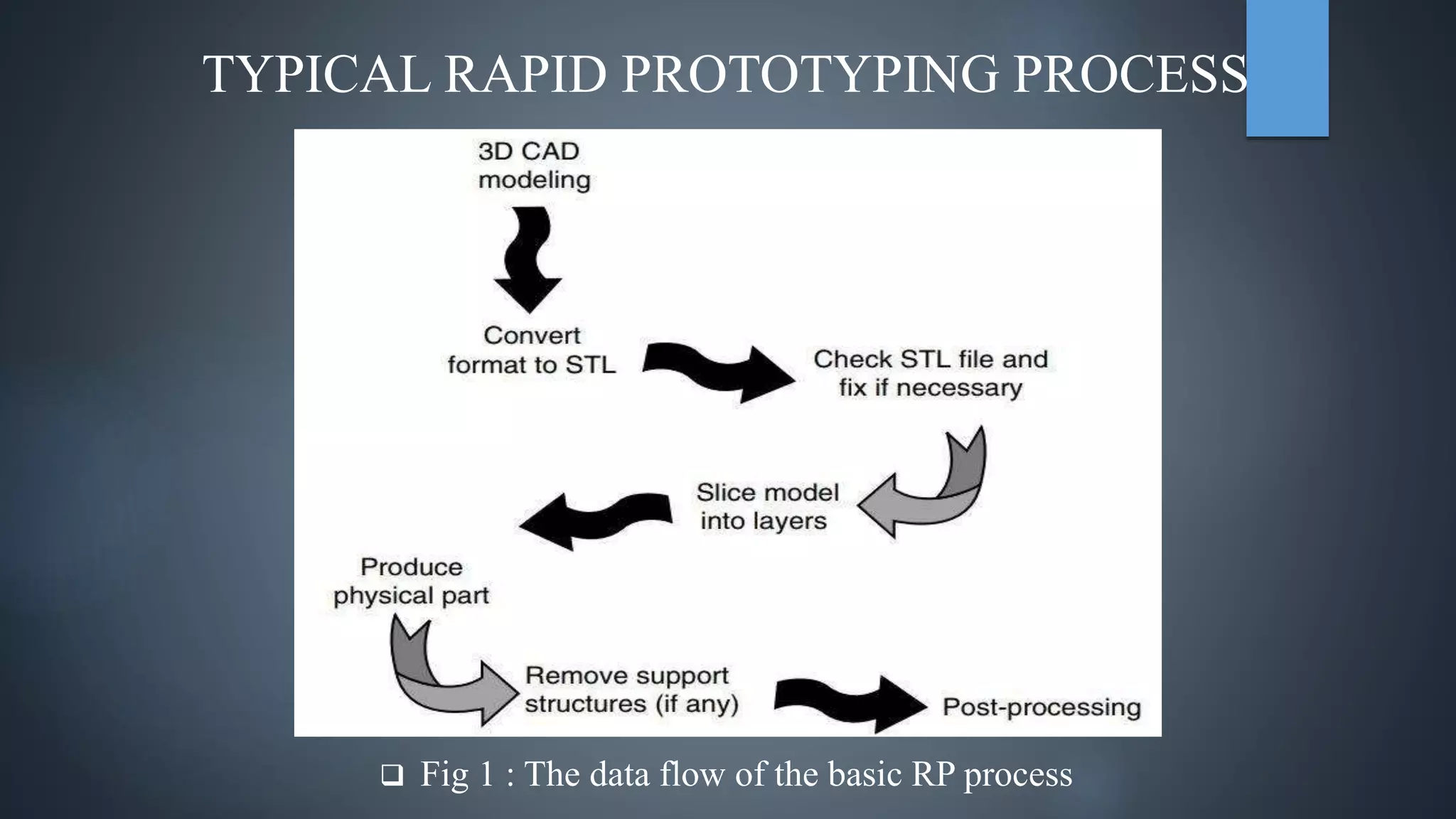

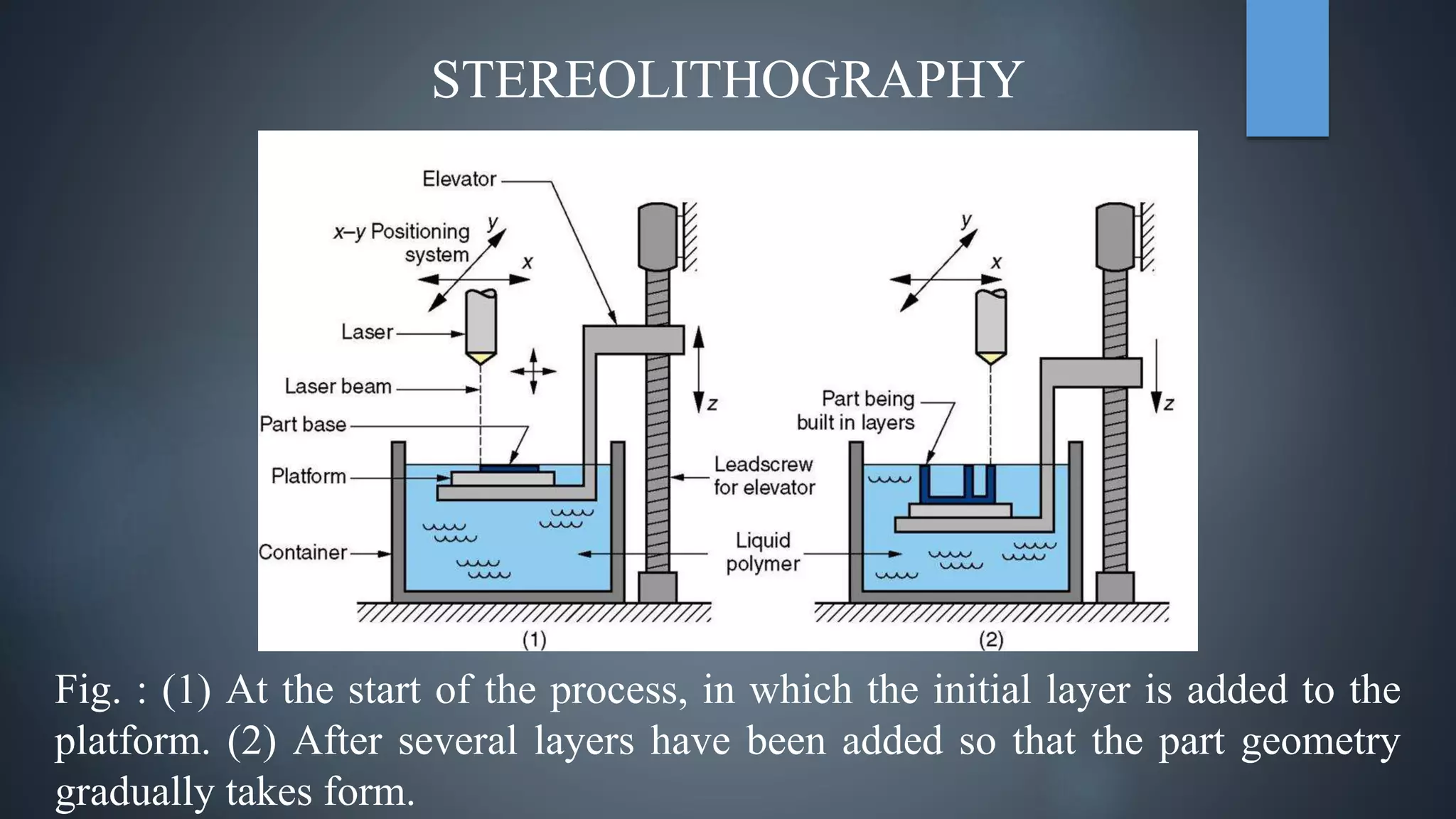

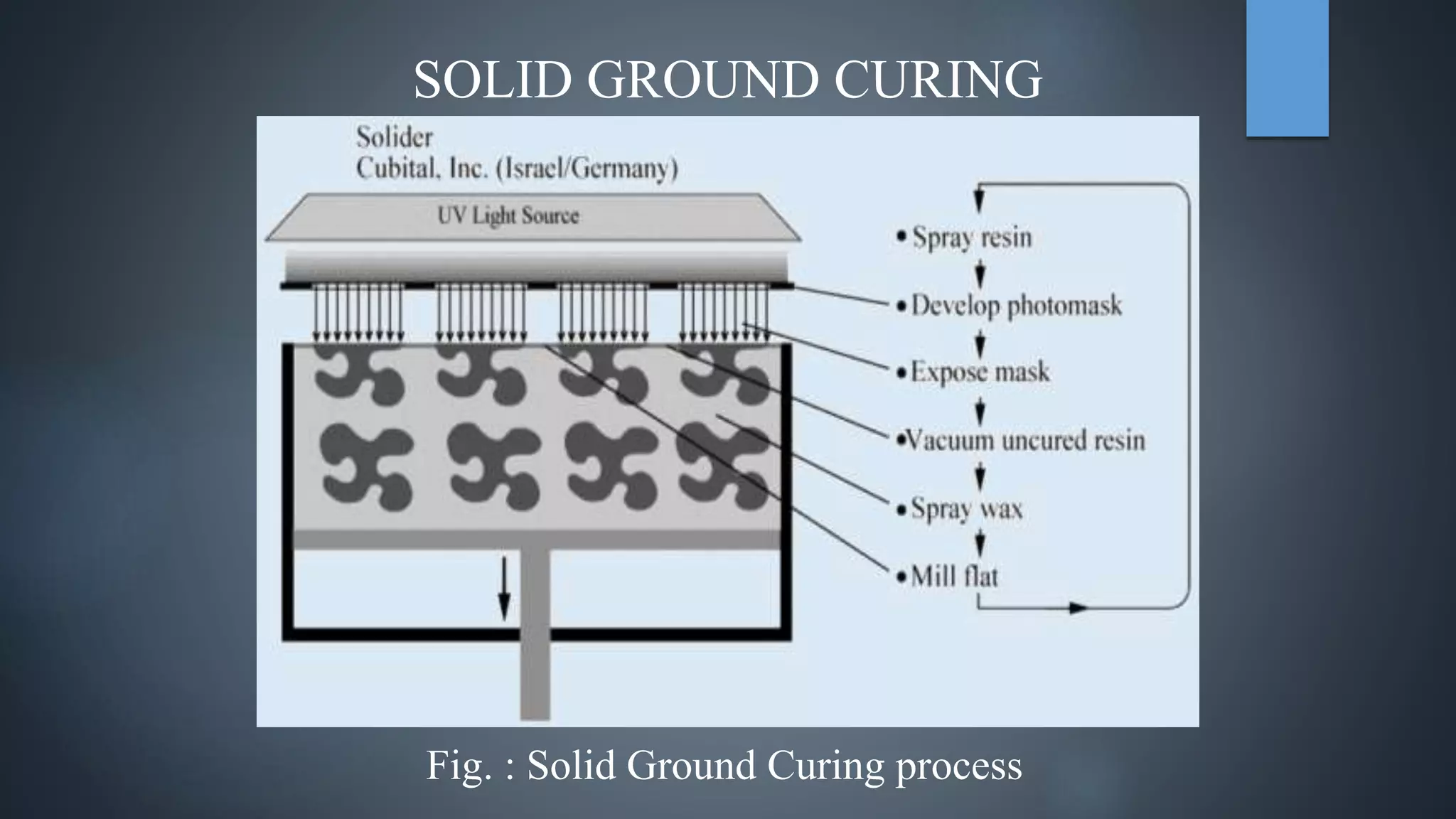

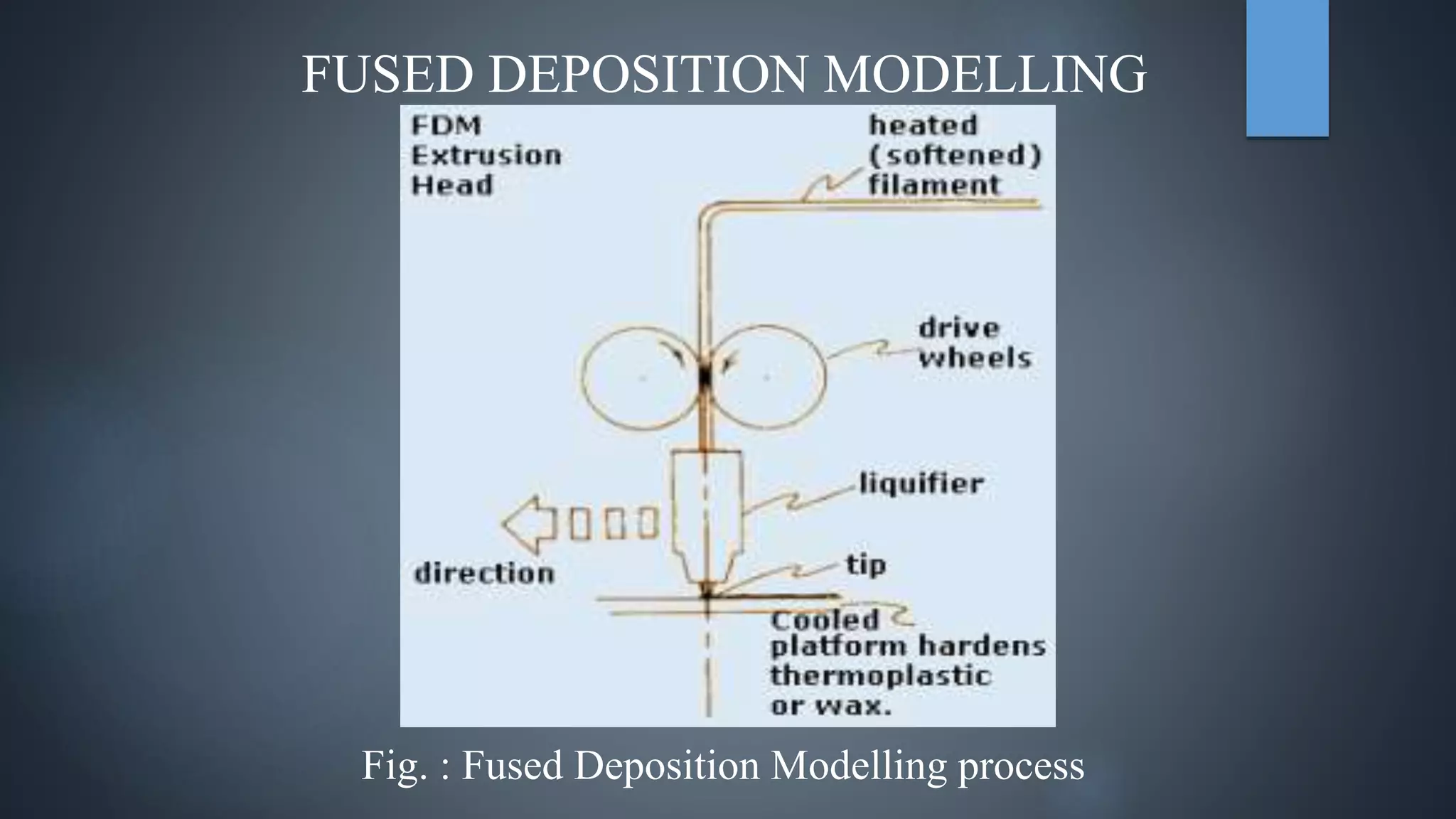

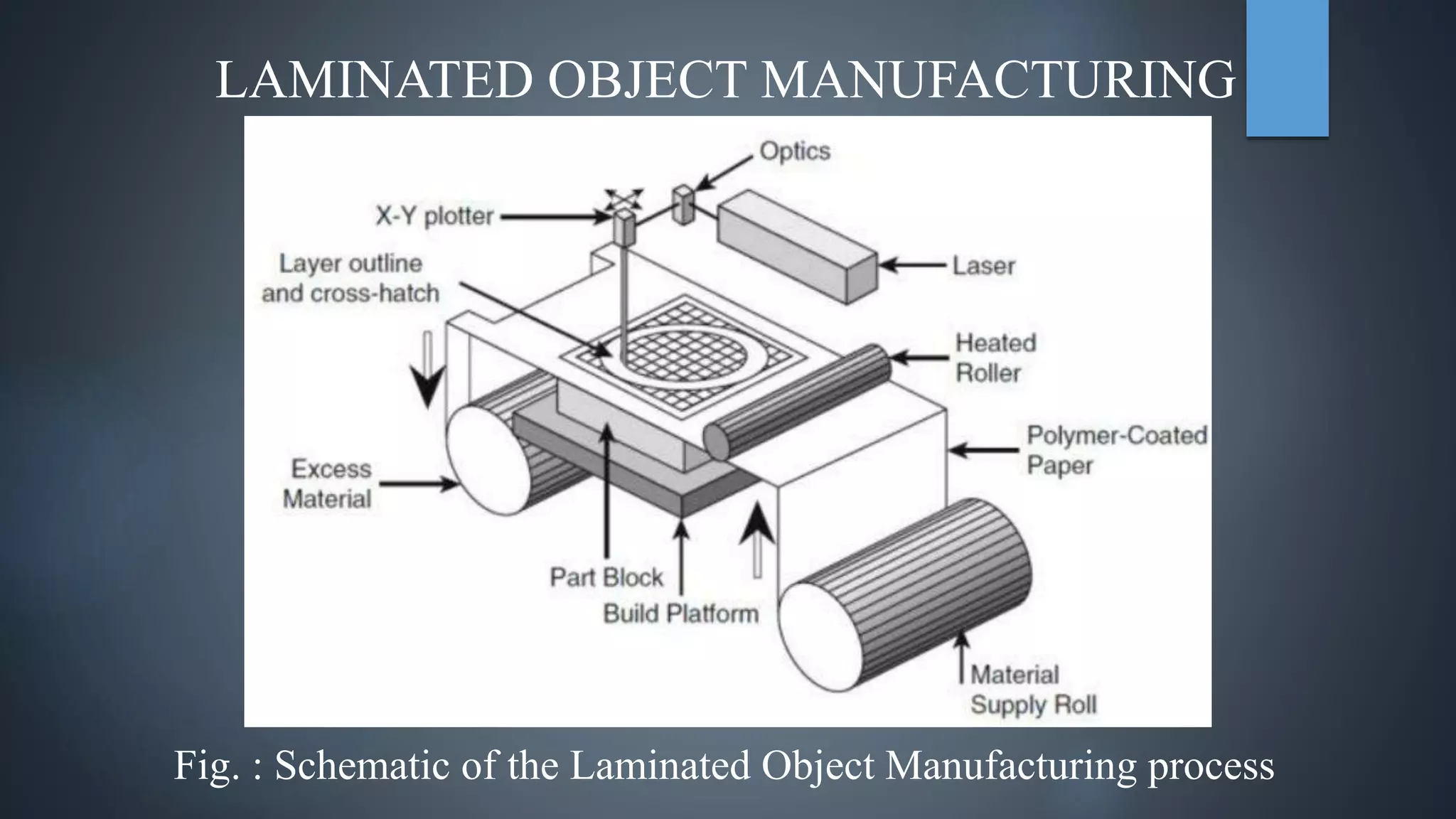

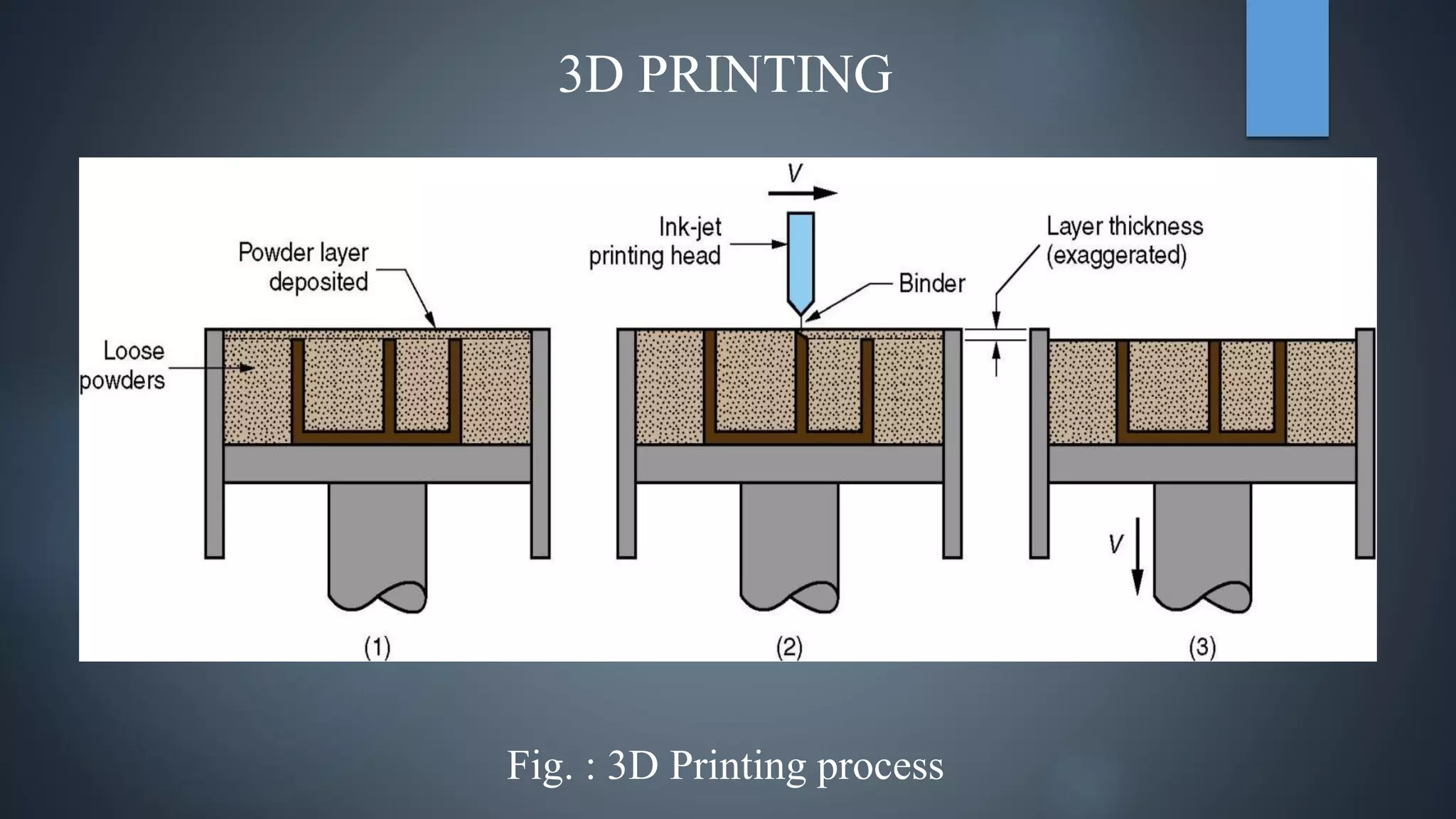

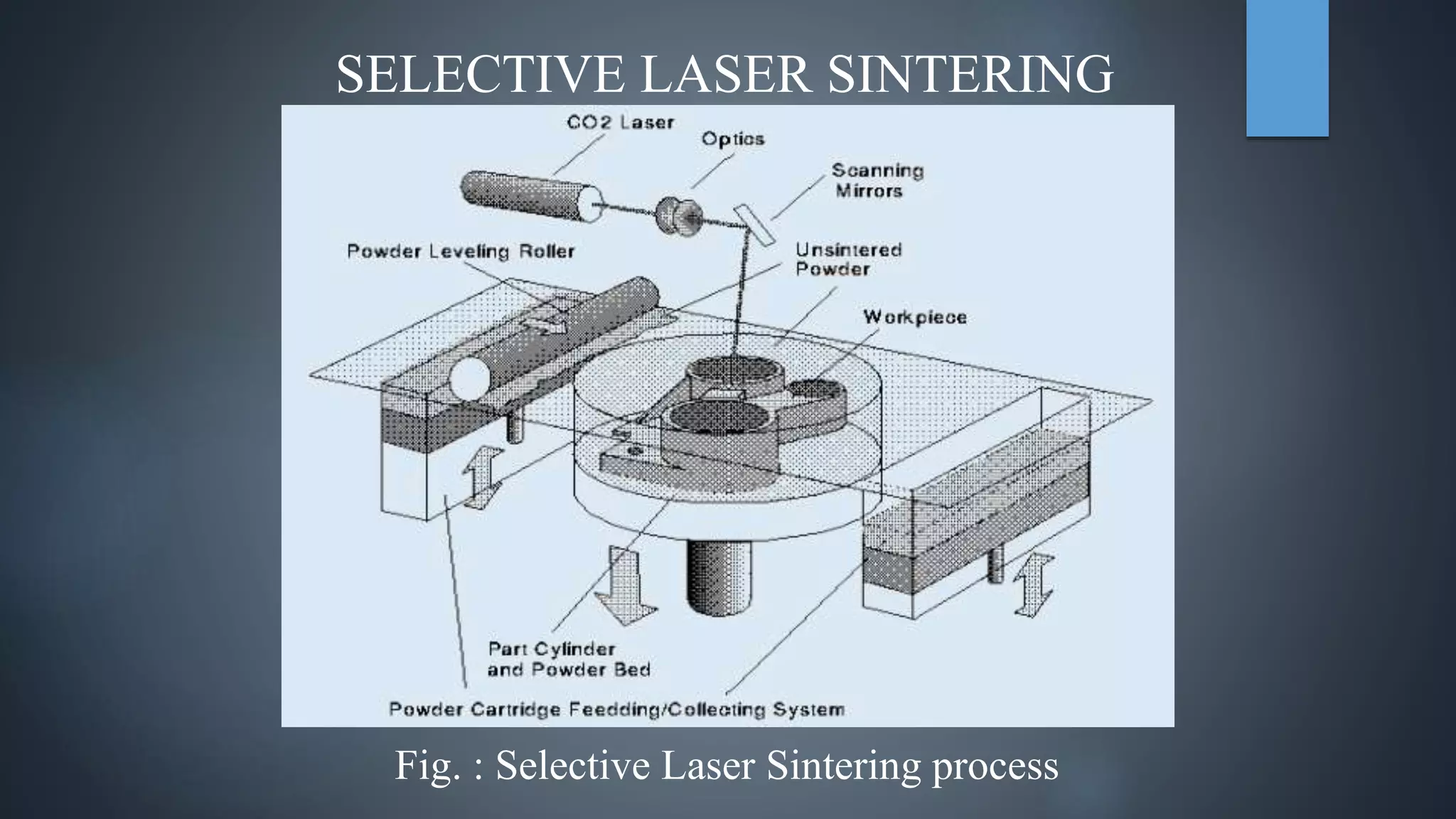

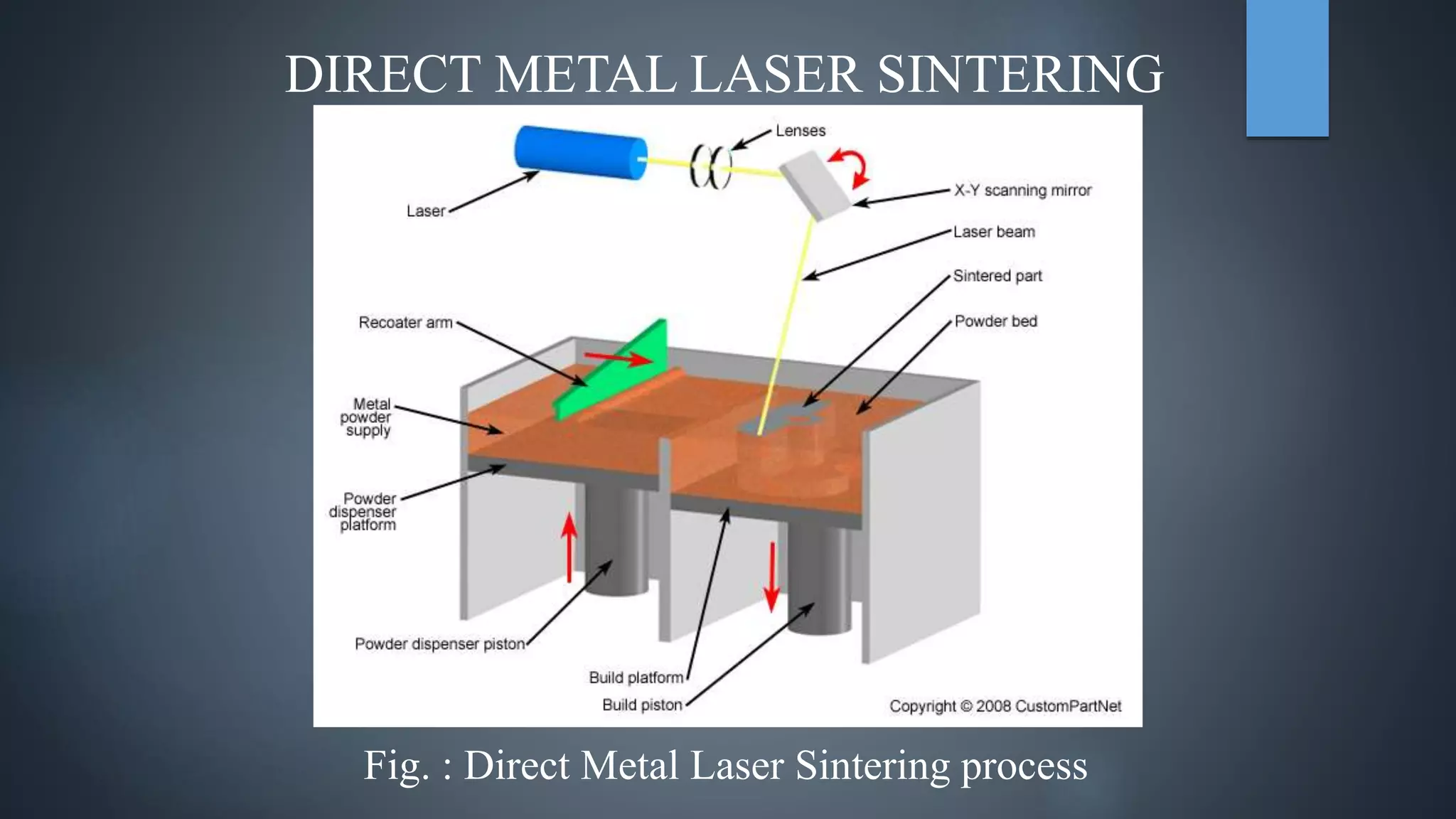

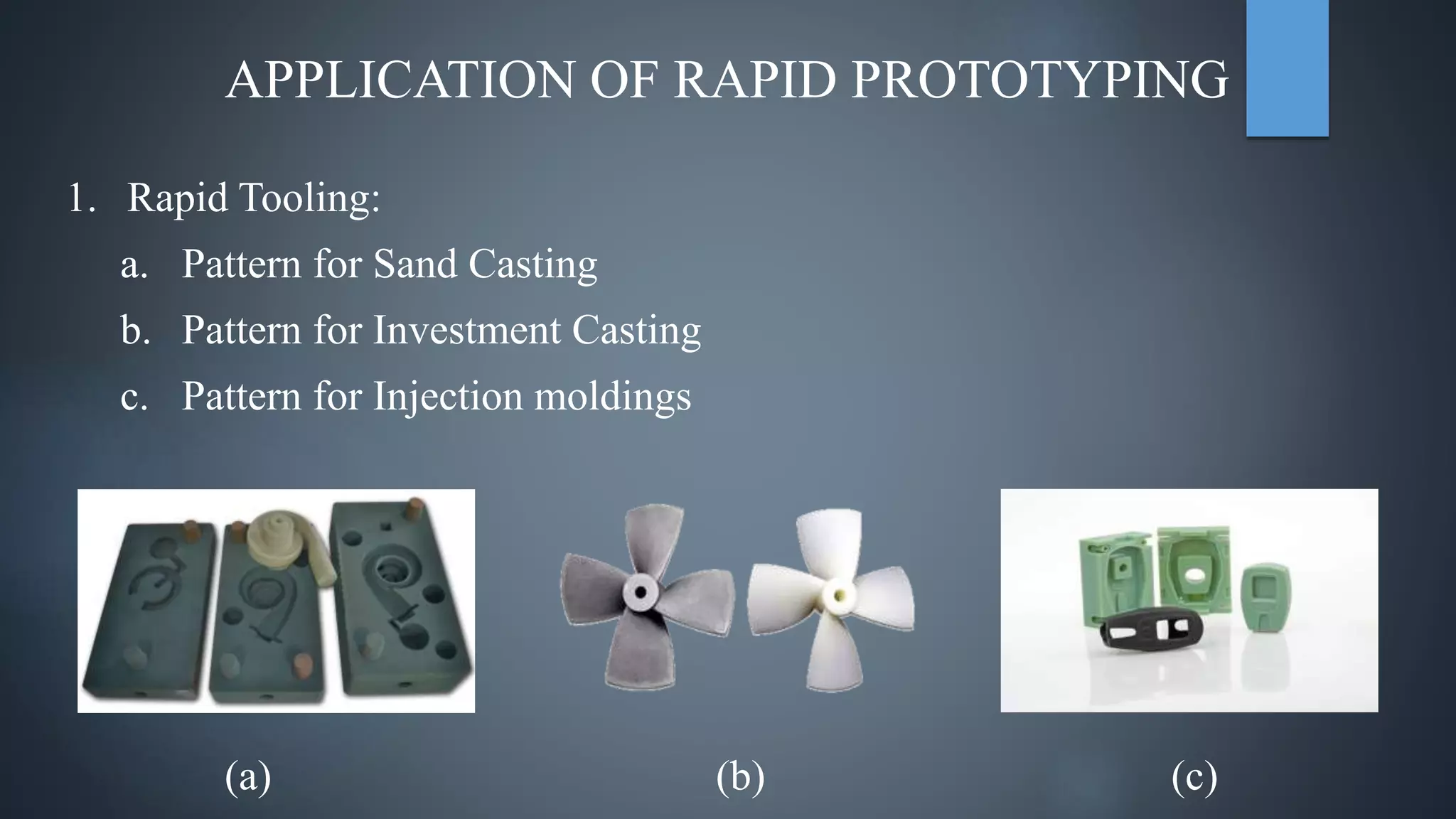

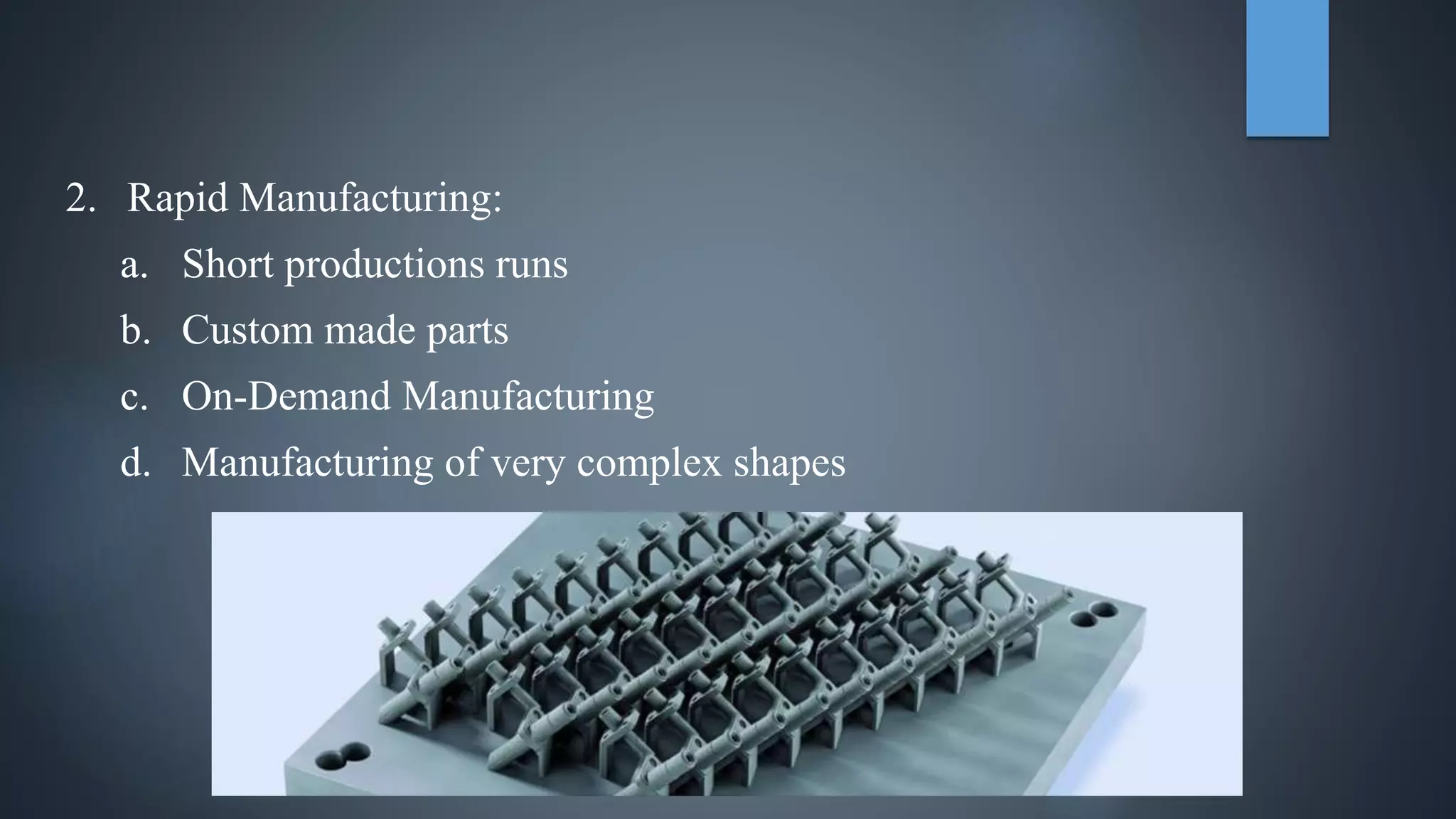

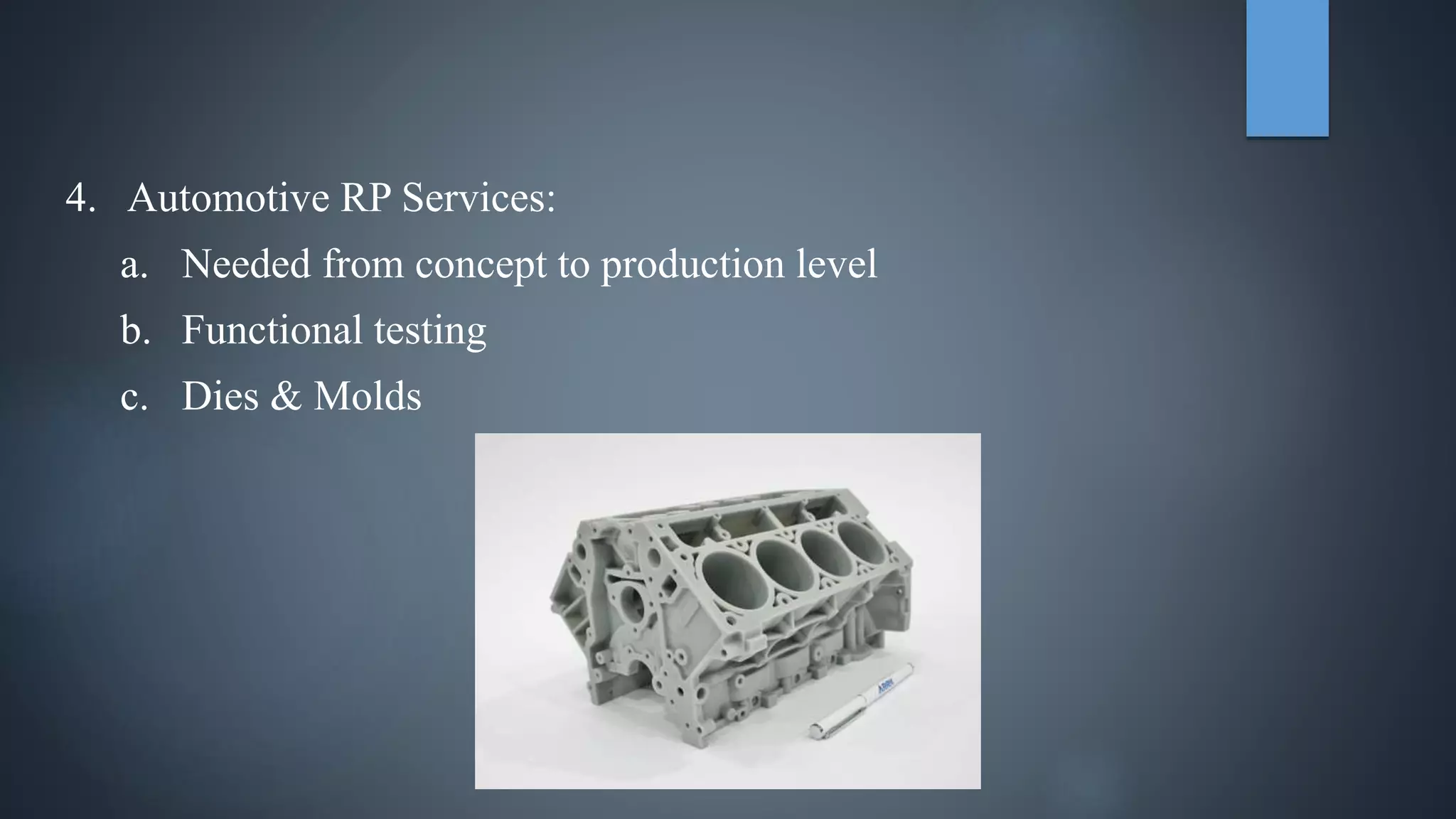

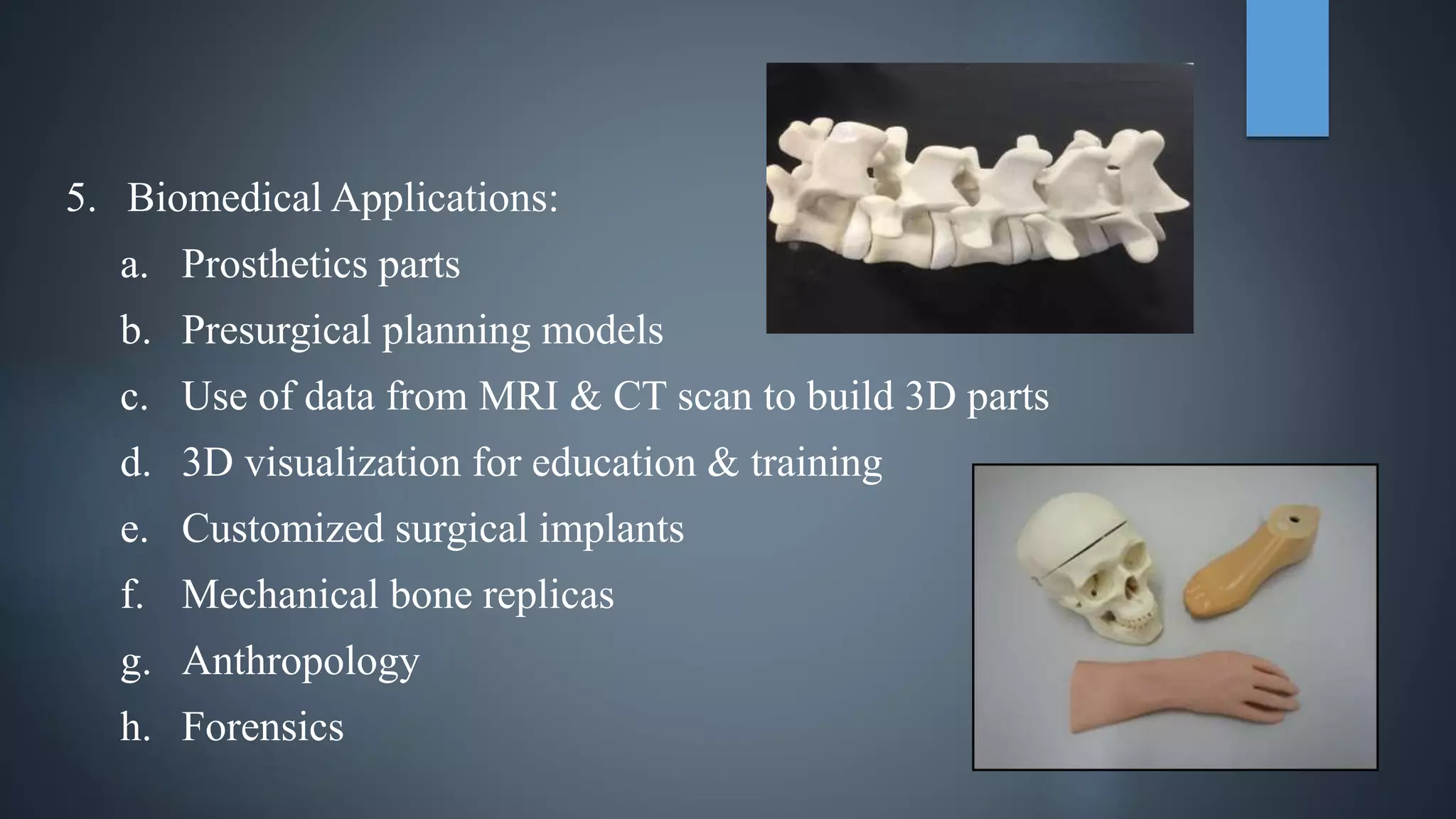

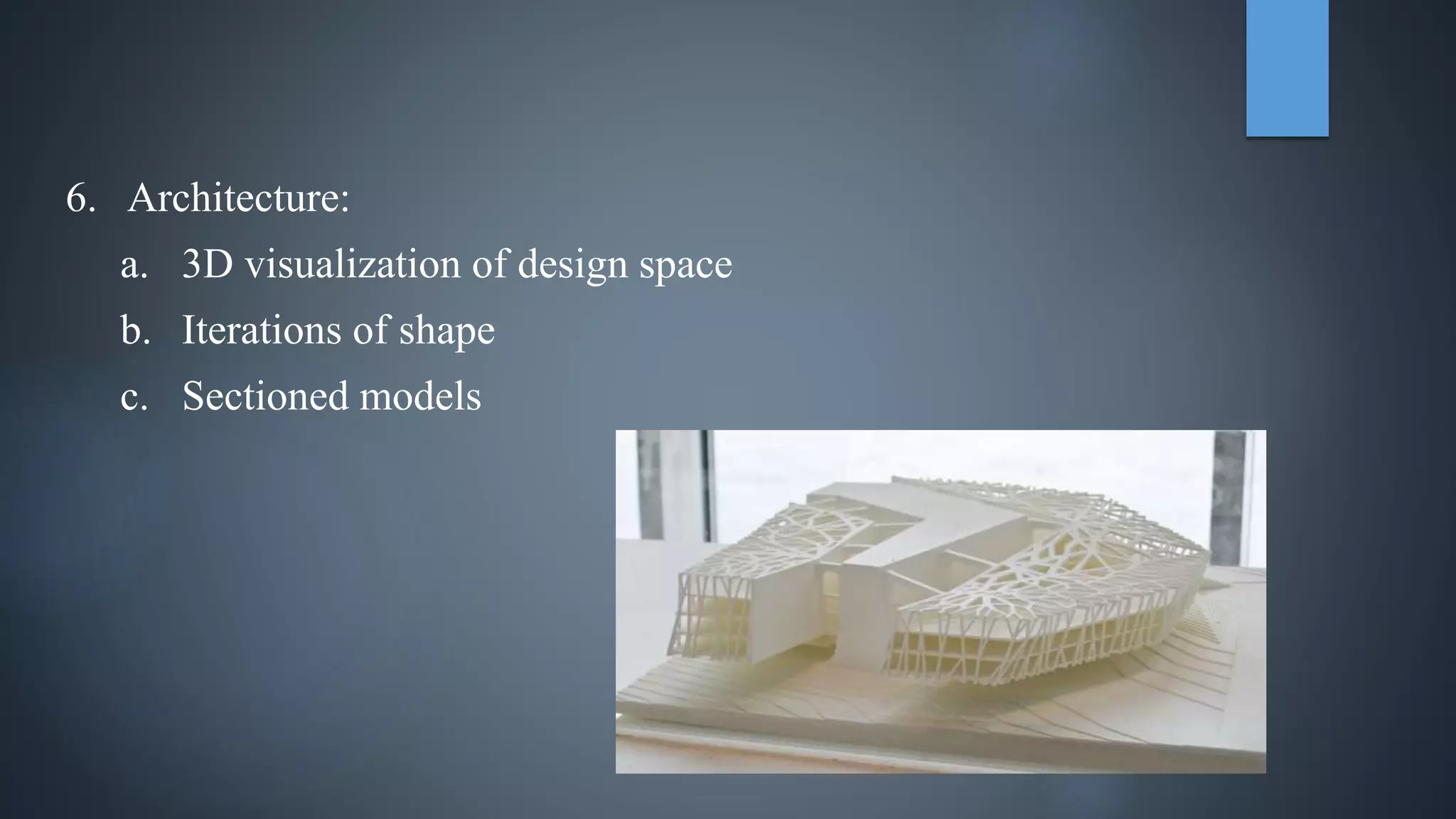

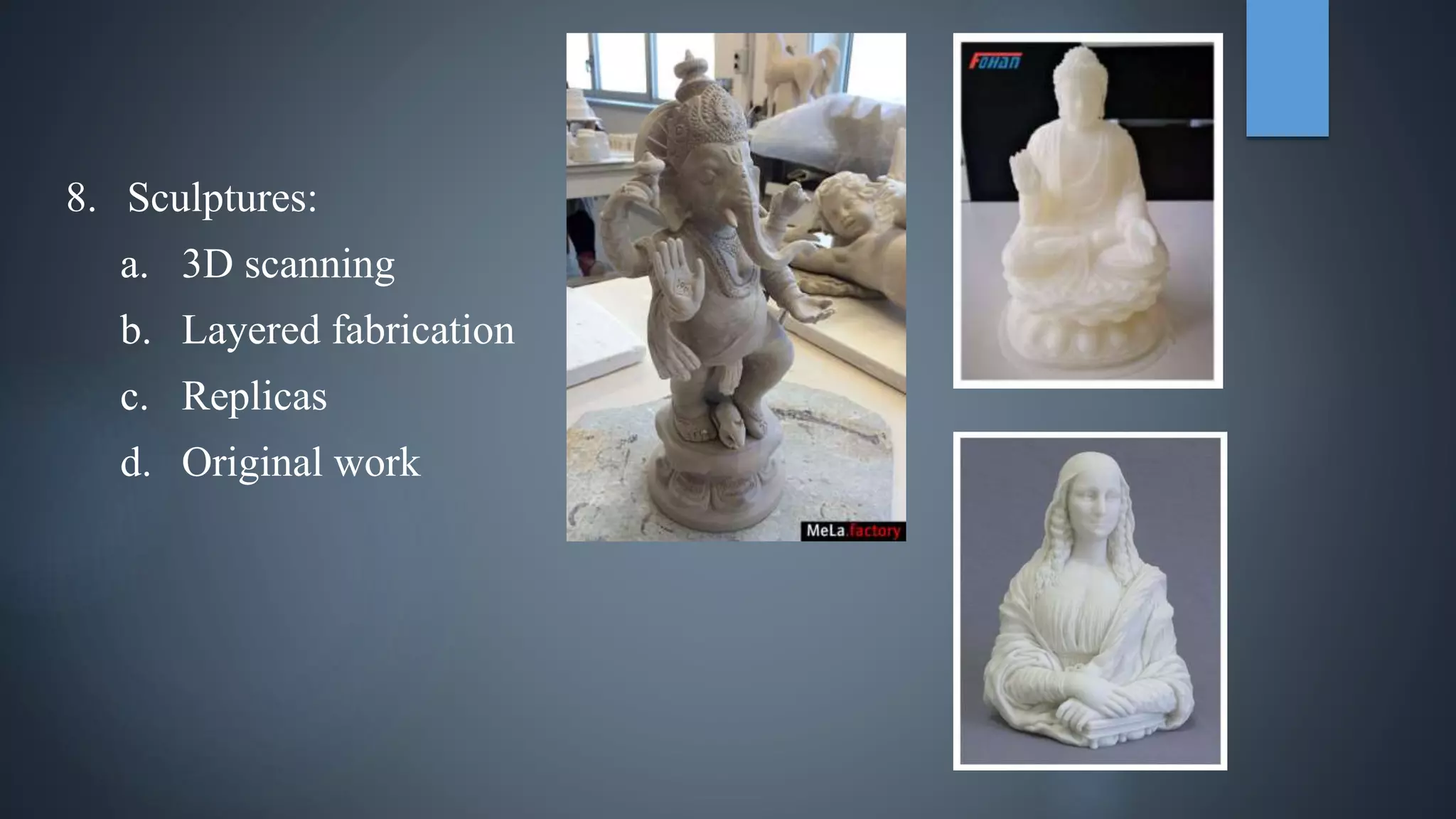

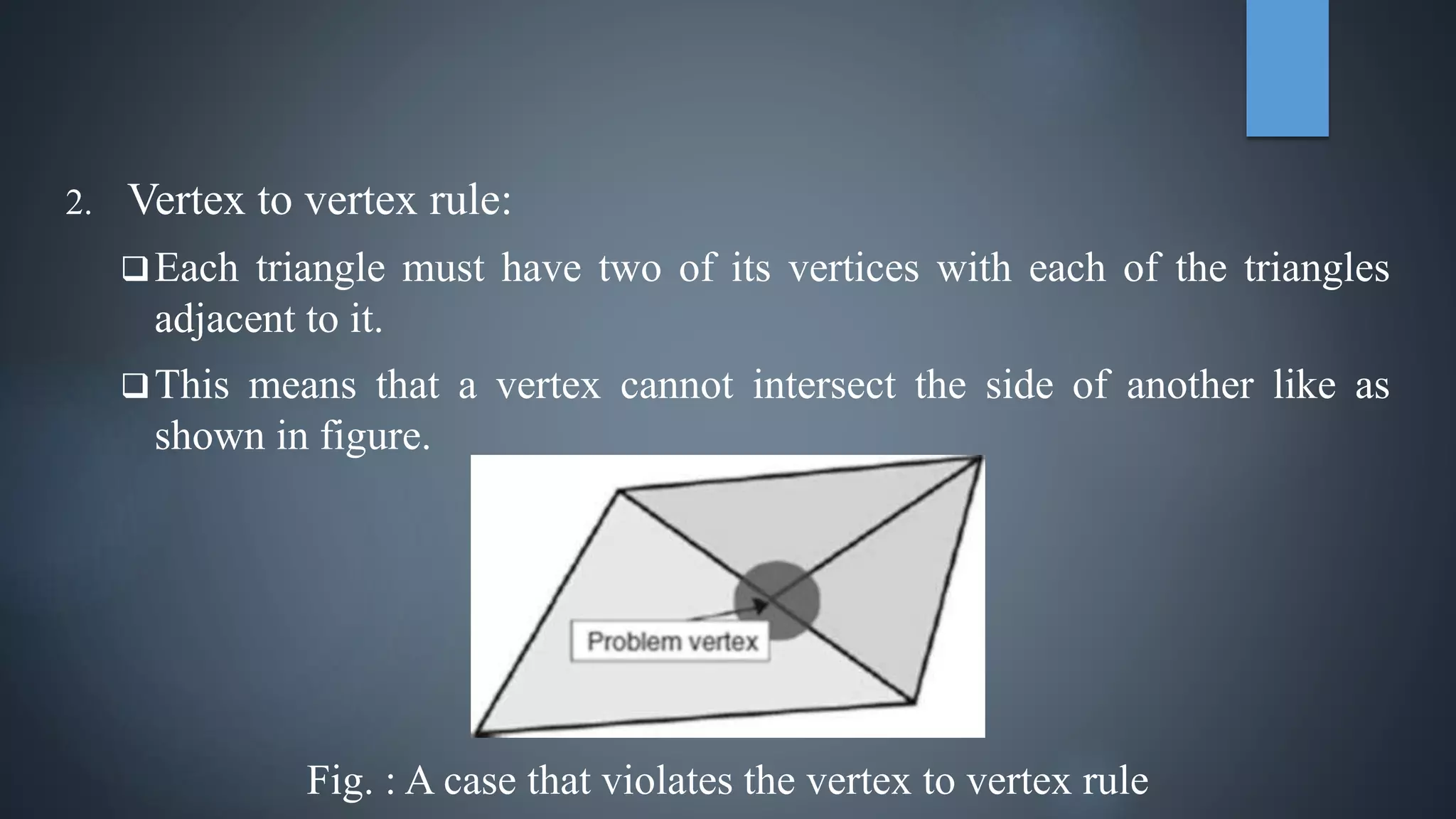

The document discusses rapid prototyping technologies that convert CAD data into physical models, categorized into liquid, solid, and powder-based processes, each with unique methods and applications. It covers various techniques such as stereolithography, fused deposition modeling, and selective laser sintering, highlighting their advantages and disadvantages, along with real-world applications in fields like aerospace, automotive, and biomedical. Additionally, the document addresses the STL file format used in rapid prototyping and common issues that can arise with file conversion.