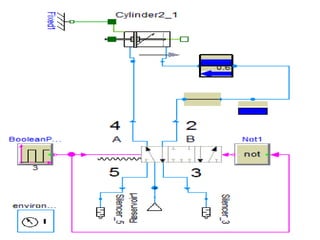

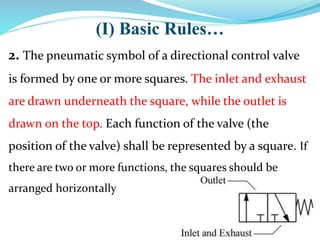

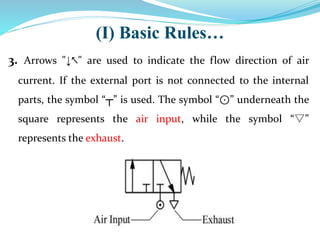

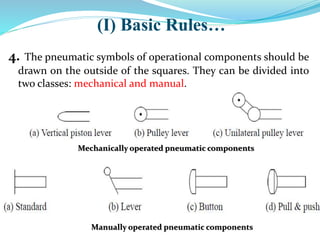

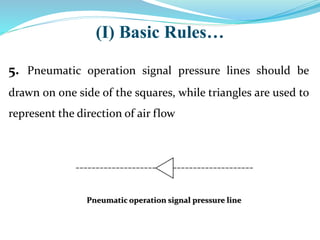

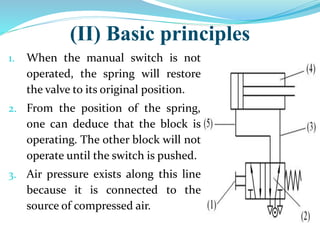

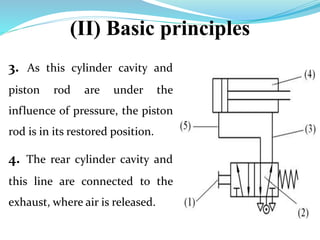

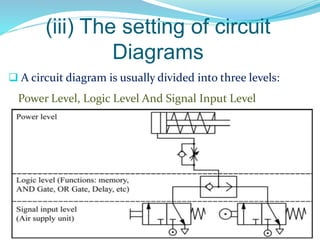

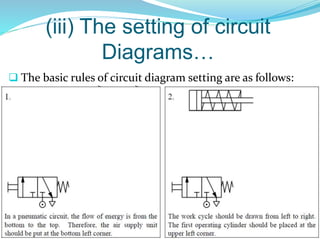

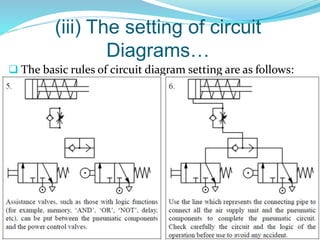

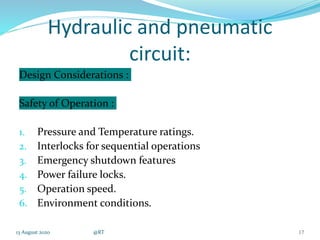

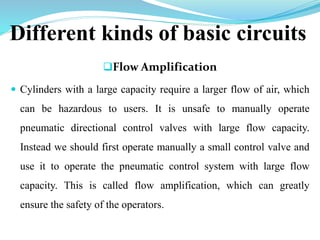

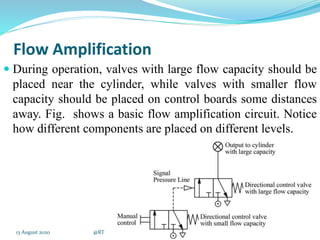

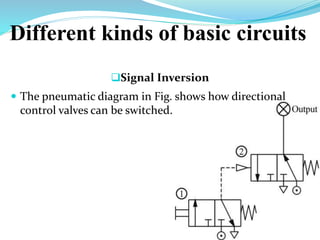

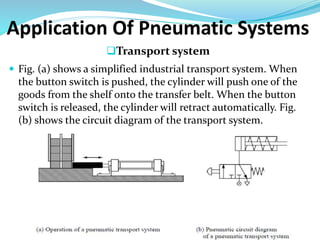

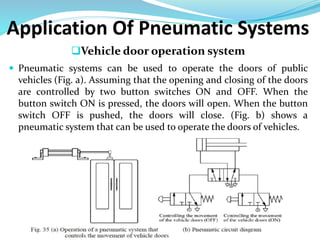

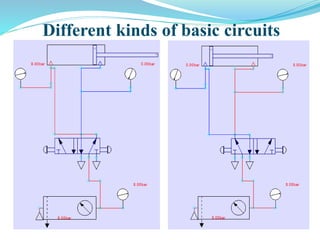

This document discusses pneumatic circuits, detailing their components, functions, and essential drawing rules for circuit diagrams. It outlines different types of circuits including flow amplification, signal inversion, and emphasizes system efficiency and safety considerations for pneumatic operations. Furthermore, it describes applications of pneumatic systems such as in transport and vehicle door operations.