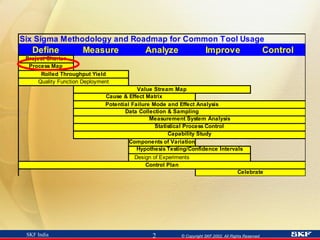

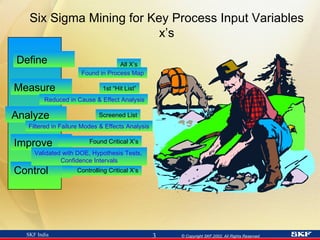

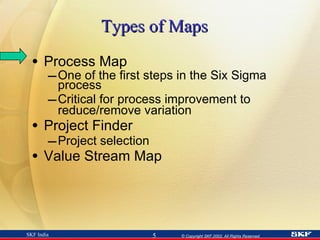

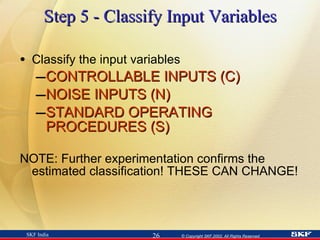

The document provides an overview of Six Sigma process mapping. It explains that process mapping is one of the first steps in a Six Sigma project and is used to gain an understanding of the process and identify potential variables influencing outputs. The key aspects of process mapping covered are: identifying the process steps, inputs, outputs and classifying inputs as controllable, uncontrollable or standard operating procedures. An example process map for an order picking process is also included.