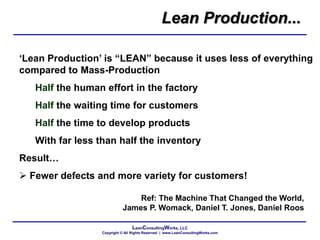

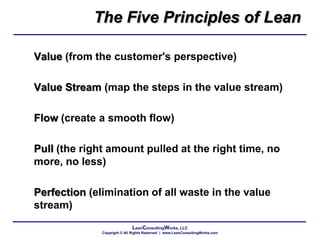

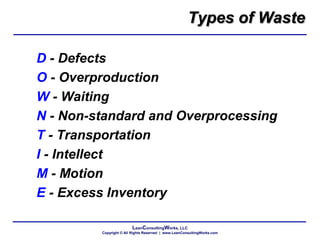

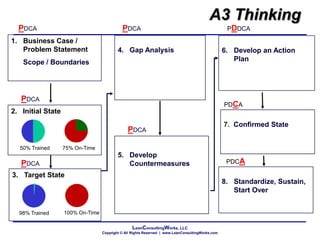

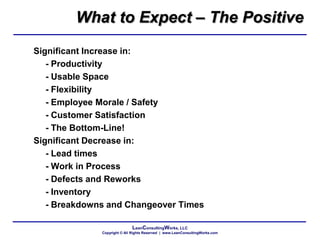

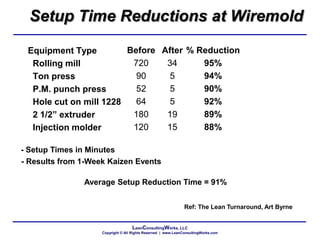

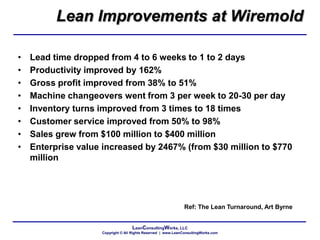

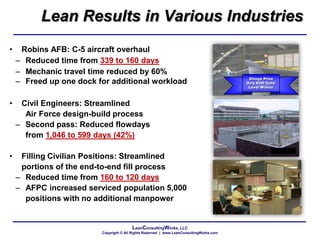

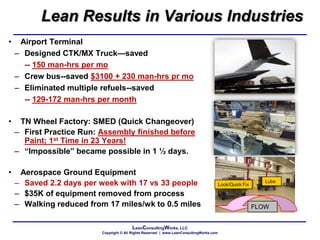

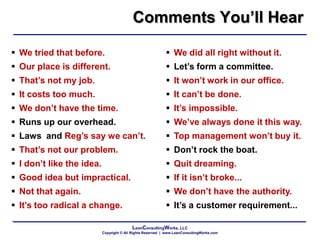

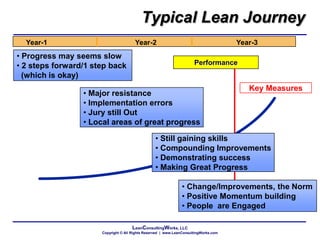

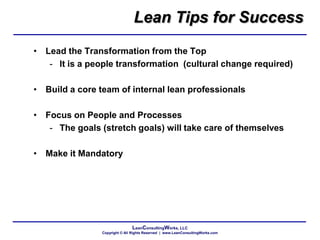

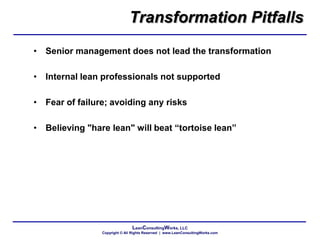

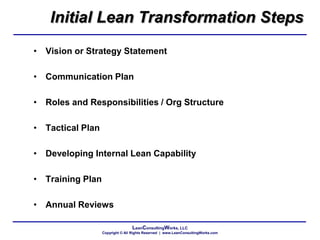

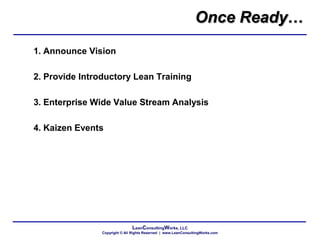

The document outlines a comprehensive overview of Lean methodology, emphasizing its principles, history, and methodologies derived from the Toyota Production System. It highlights the importance of creating customer value, continuous improvement, and eliminating waste to enhance productivity and efficiency. Additionally, it provides practical tips for successful lean transformation and shares examples of notable successes in various industries.