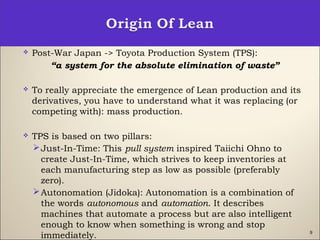

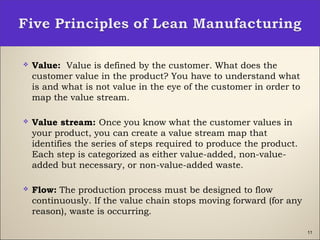

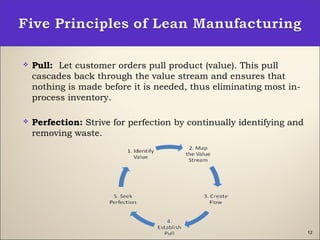

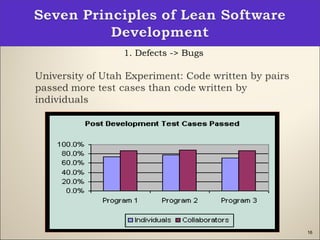

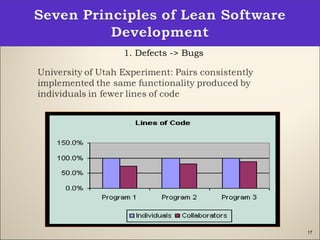

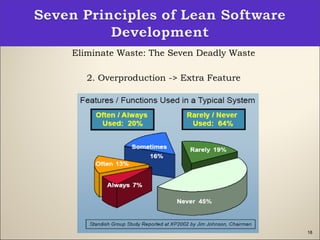

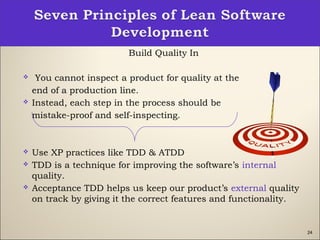

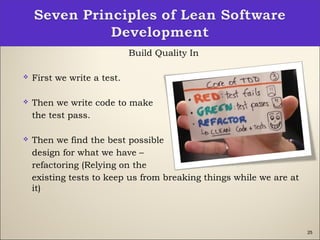

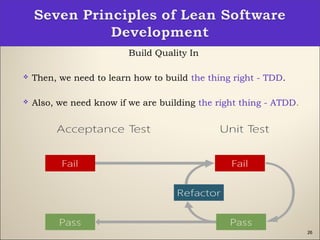

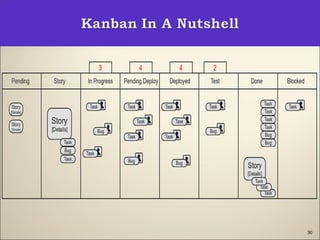

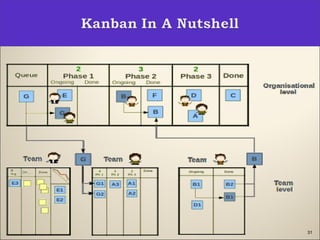

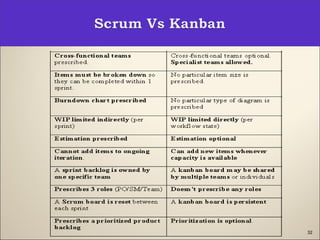

Rishi Chaddha introduces lean software development principles. He discusses the origins of lean from the Toyota Production System and its focus on eliminating waste. The presentation then covers the seven principles of lean software development which include eliminating waste, building quality in, deferring commitment, delivering fast, respecting people, and optimizing the whole. Kanban and various agile practices are presented as tools that can be mixed and matched to implement lean ideas.