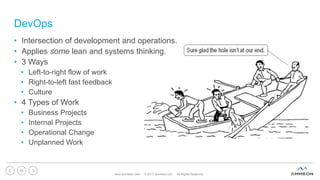

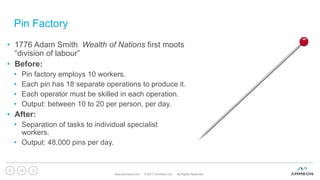

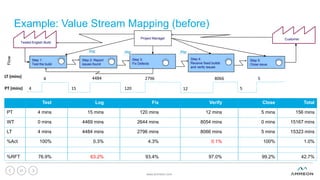

The document discusses continuous improvement in lean processes. It begins by outlining the speaker's goals of changing how people think about technology, approach lean process improvement, and treat other people. It then provides examples of how small changes to processes can significantly improve outcomes. This includes reducing wait times for paint to dry from 9 hours to 2 minutes. Overall, the document advocates for continual improvement of processes through lean principles and techniques.

![Challenge: Rapidly Changing Customer Requirements

www.ammeon.com © 2017 Ammeon Ltd. All Rights Reserved.

27

Credit: Al Goerner [1]](https://image.slidesharecdn.com/continuousimprovementinlean-181212180449/85/Continuous-Improvement-in-Lean-27-320.jpg)