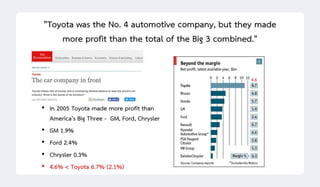

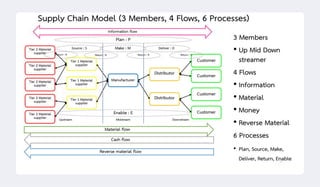

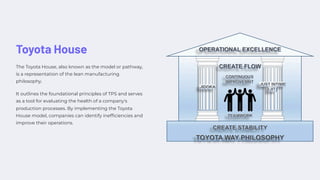

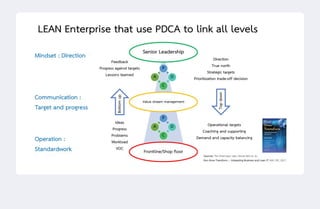

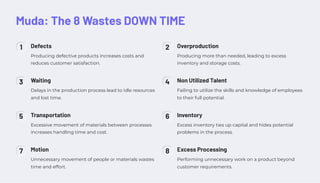

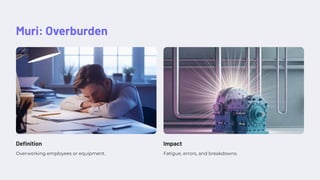

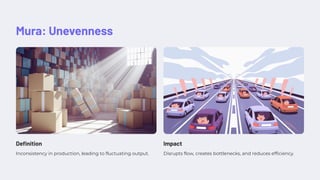

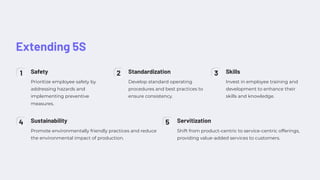

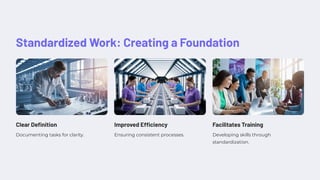

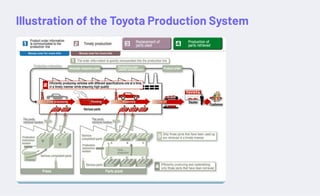

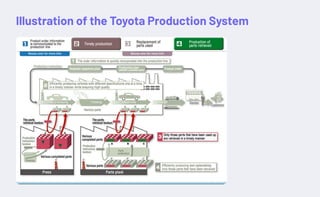

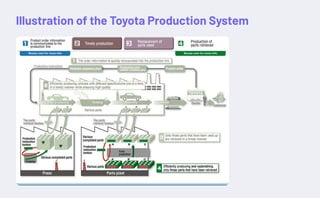

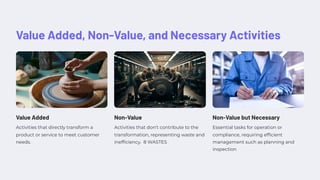

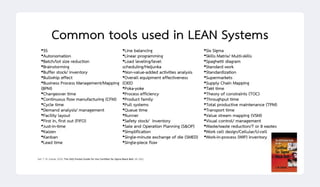

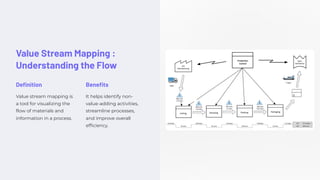

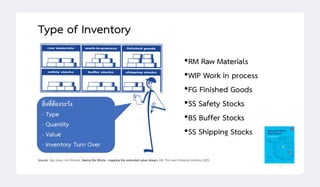

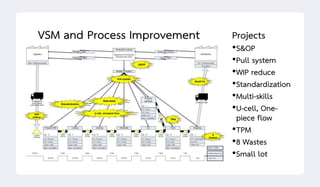

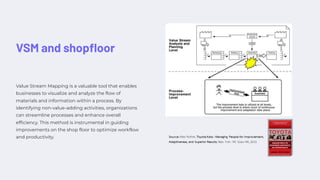

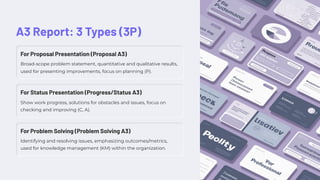

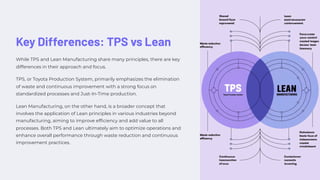

This document compares the Toyota Production System (TPS) and lean manufacturing, detailing their principles, applications, and differences. It emphasizes waste elimination, continuous improvement, and methodologies like value stream mapping and kaizen in various sectors, including automotive and healthcare. The discussion highlights the evolving nature of lean practices, especially with the integration of digital technologies and a focus on sustainability.