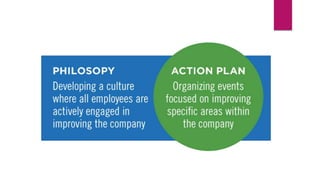

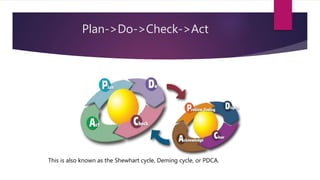

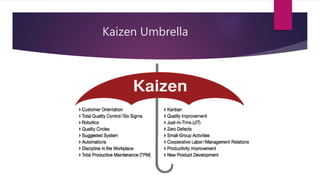

Kaizen refers to continuous improvement activities that involve all employees. It aims to improve all functions of a business through small, incremental changes. As both an action plan and a philosophy, Kaizen emphasizes organizing events to improve specific areas and building a culture where all employees suggest and implement improvements. It is implemented through approaches like kaizen blitzes and bursts to identify and remove waste, following the PDCA cycle of plan, do, check, act. Proper training and guidelines ensure changes are discussed and safety protocols followed before implementation. Management must also support more suggestions for improvements and changes through kaizen.