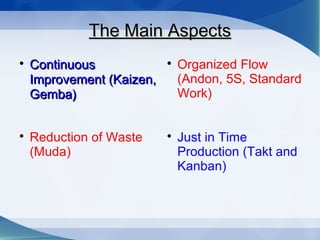

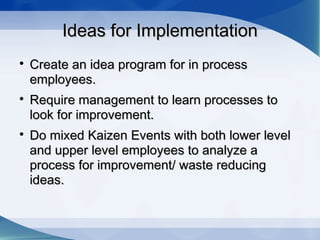

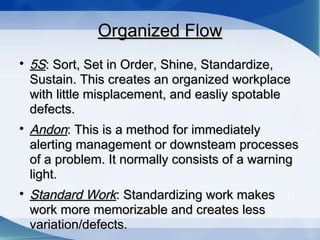

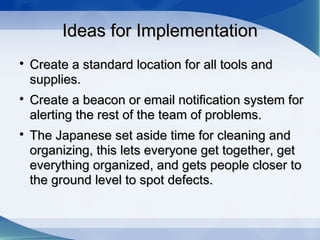

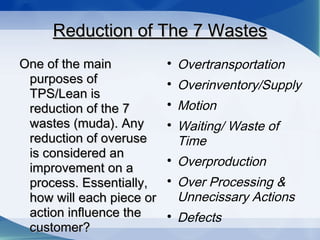

The document introduces the Toyota Production System and lean manufacturing, highlighting its origins and principles such as waste reduction, continuous improvement, and organized flow. It discusses key concepts like kaizen, just-in-time production, and the seven types of waste, while providing implementation ideas to enhance efficiency. The emphasis is on the importance of engaging employees, standardizing processes, and creating a culture of improvement in the workplace.