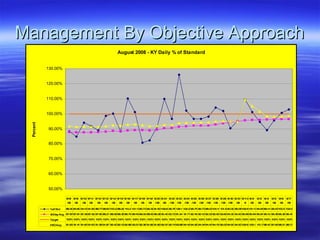

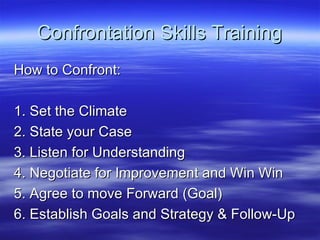

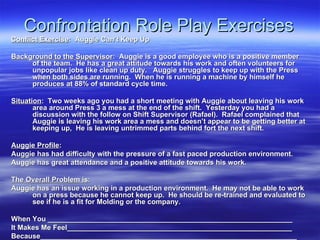

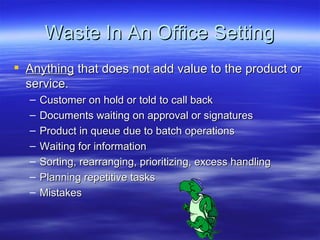

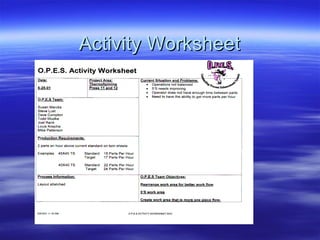

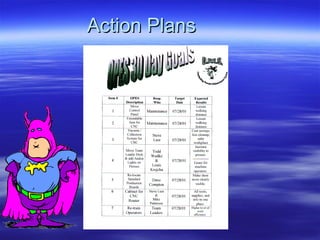

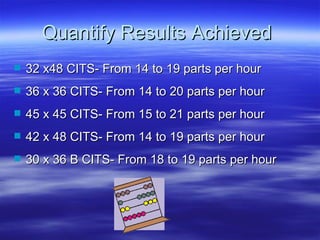

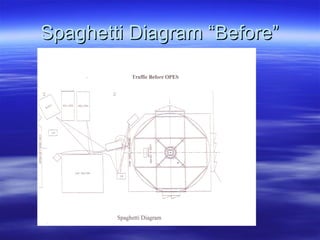

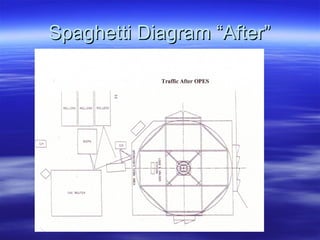

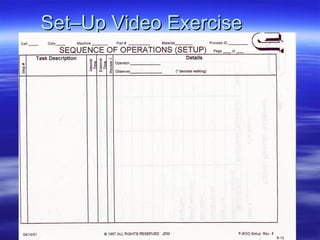

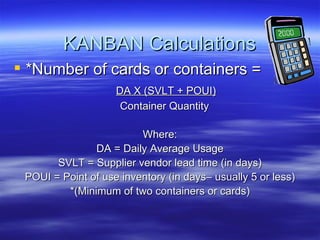

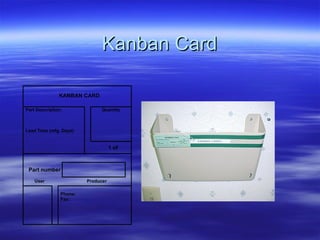

The document provides an overview of Joe Weiss's skills in management by objective, confrontation skills training, and lean manufacturing experience. It includes descriptions of confrontation skills training techniques, a confrontation role play exercise scenario, and explanations of lean concepts like kaizen, eliminating waste, 5S, visual management, SMED, kanban, and cellular manufacturing principles.