This document provides an overview of Kaizen and its key principles and processes. Some main points:

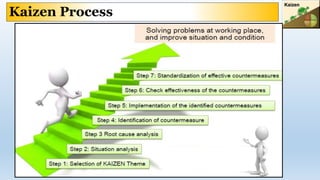

- Kaizen focuses on continuous improvement through small, incremental changes to processes. It was first introduced at Toyota plants in Japan.

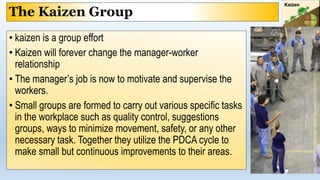

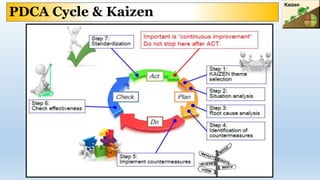

- The PDCA (Plan-Do-Check-Act) cycle is used to ensure continuous improvement. It involves planning a change, implementing it, checking if it worked, and acting to standardize it if successful.

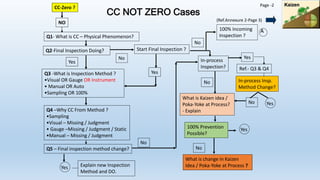

- Quality is the top priority in Kaizen. Both products and processes must be of high quality.

- Data collection is important for identifying problems and tracking improvements. Each worker should see the next process as their customer.

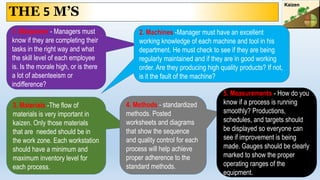

- The "5 Ms