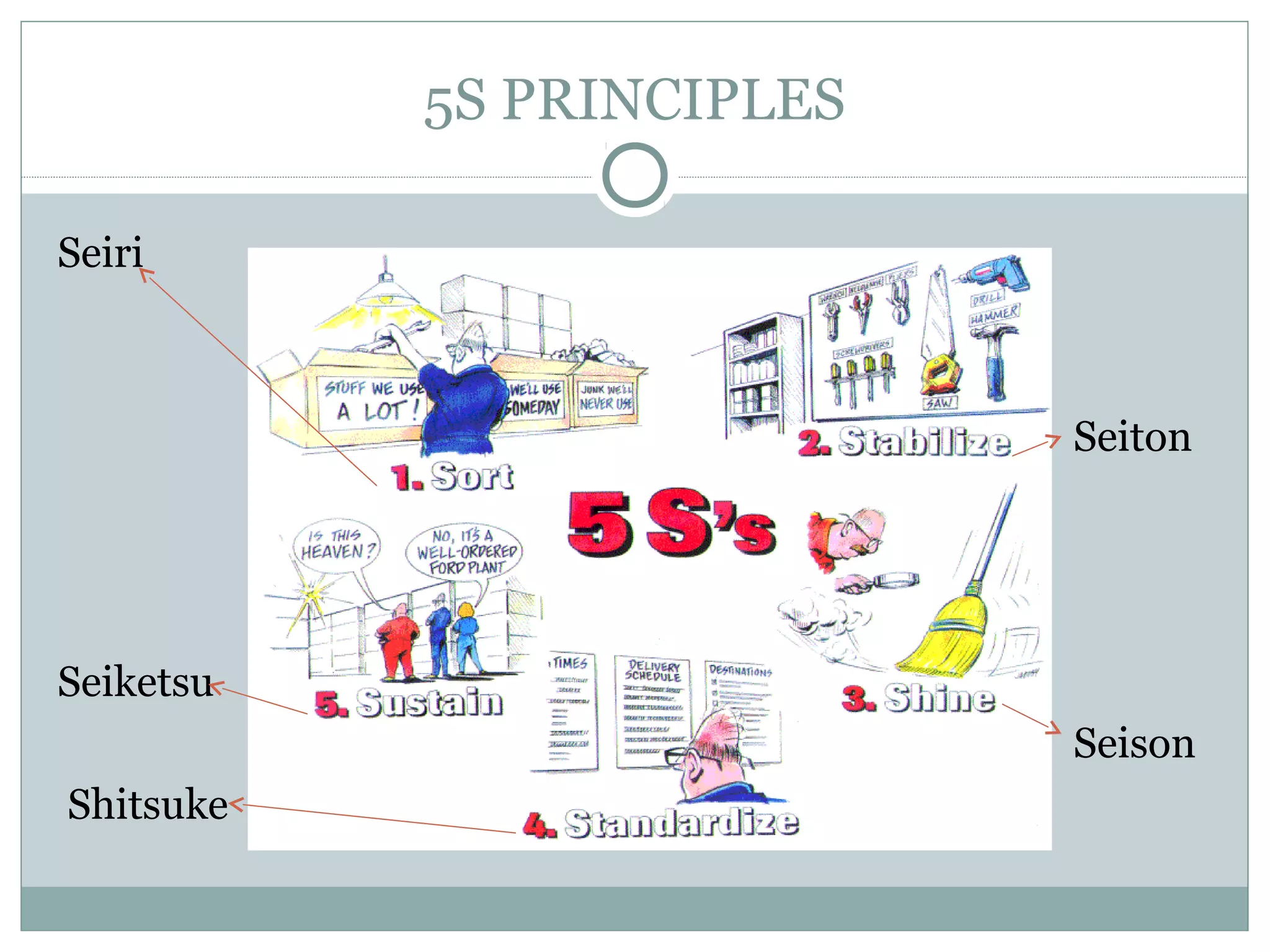

This document discusses the concept of Kaizen, a Japanese management philosophy that focuses on continuous improvement. It involves defining problems, assessing current status, finding root causes, planning and implementing countermeasures, verifying results, and standardizing processes. A key tool in Kaizen is the 5S framework, which stands for Sort, Set in Order, Shine, Standardize, and Sustain. The 5S principles aim to create an organized, clean, and well-maintained workplace through eliminating unnecessary items, efficiently arranging necessary items, cleaning and maintaining work areas, standardizing processes, and sustaining standards through self-discipline and auditing. Kaizen emphasizes teamwork, quality improvement, and making incremental changes to optimize operations.