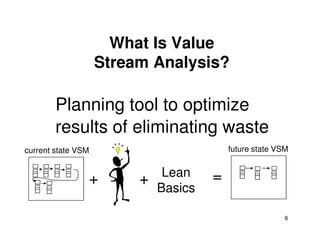

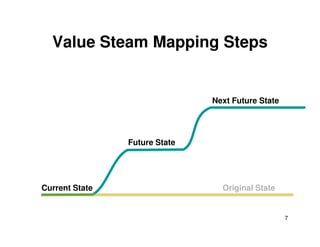

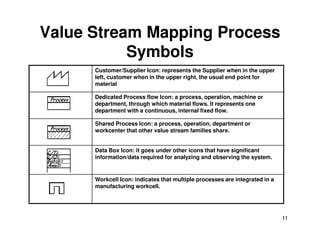

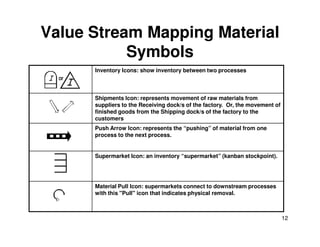

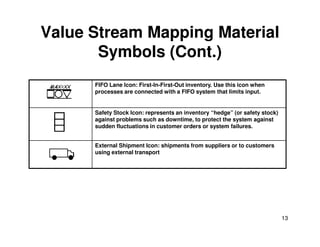

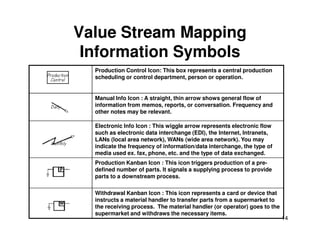

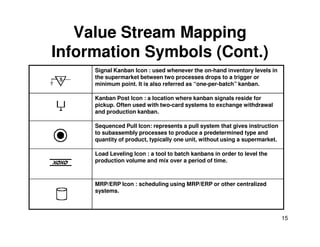

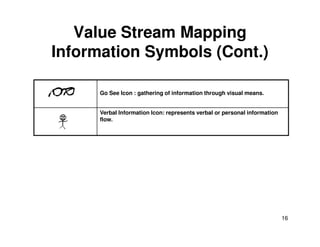

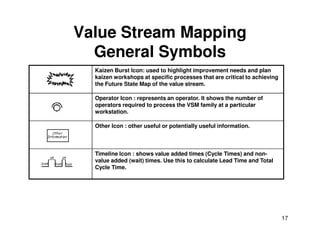

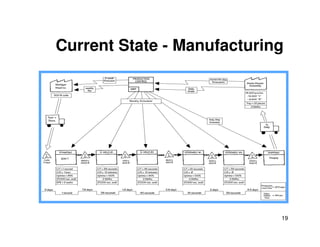

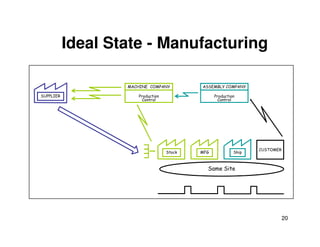

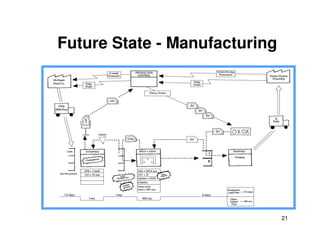

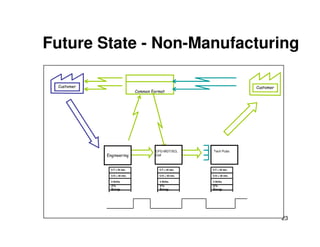

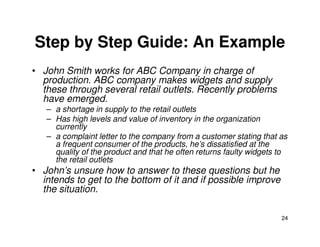

Value stream mapping (VSM) is a tool that uses symbols to depict and improve the flow of inventory and information through a process. It makes waste visible and allows organizations to plan its elimination. VSM involves mapping the current state, identifying areas for improvement, and designing a future state with minimum waste. Key steps include selecting a process to map, collecting data on times and flows, critiquing the current state, and creating an action plan to implement the future state design.