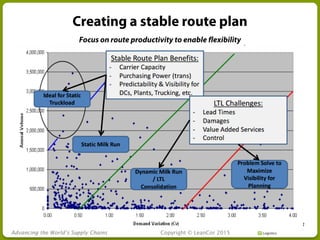

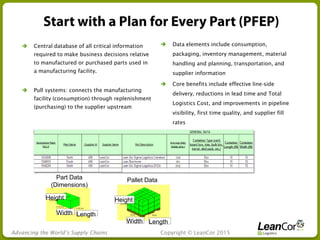

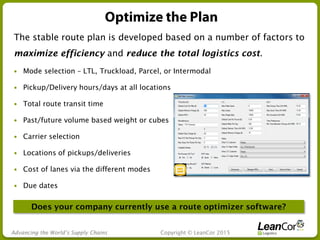

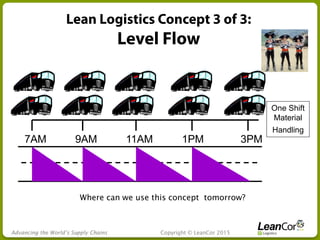

The document details a webinar on advancing supply chains, highlighting the expertise of LeanCor professionals in lean logistics, transportation management, and warehouse solutions. It addresses challenges in supply chain management, such as increasing costs and changing customer demands, and promotes the value of stable route planning for optimizing logistics efficiency. Key benefits of the discussed solutions include improved operational excellence and enhanced relationships with carriers and customers.