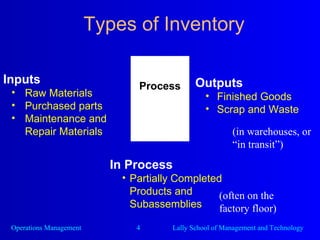

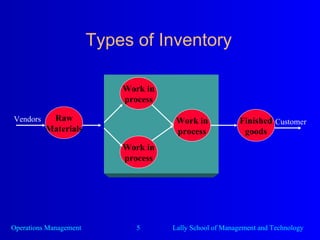

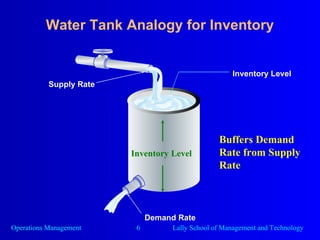

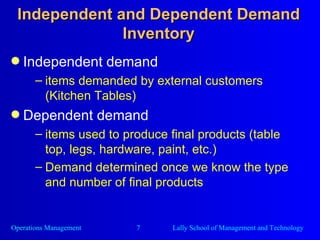

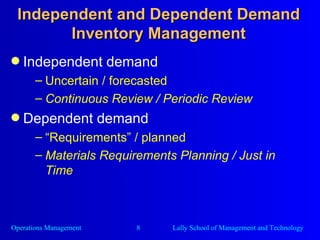

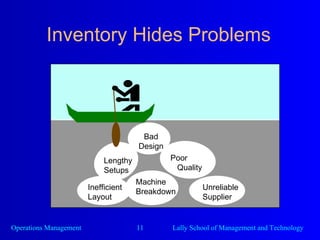

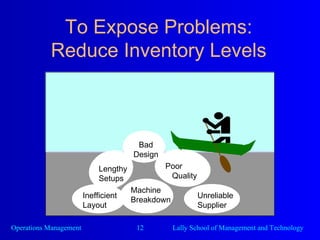

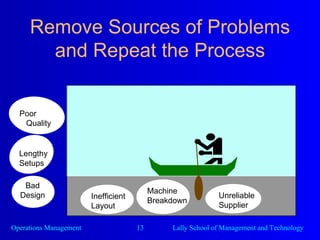

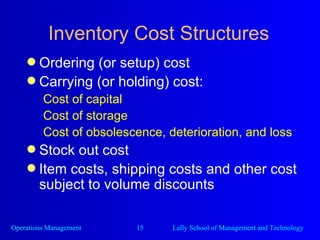

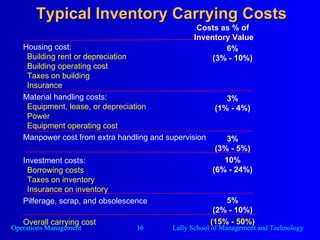

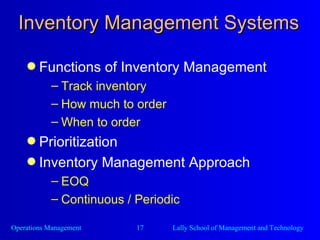

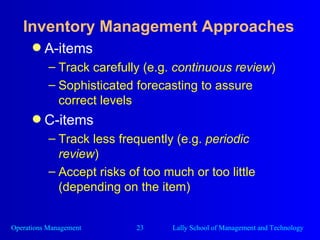

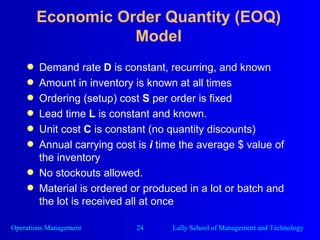

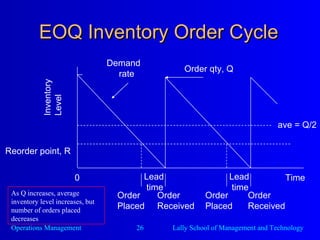

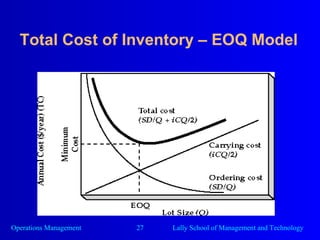

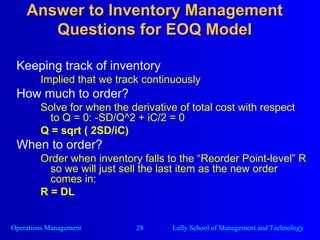

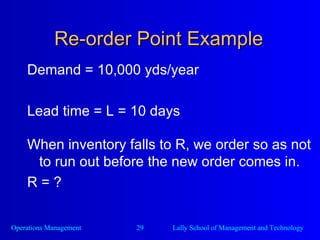

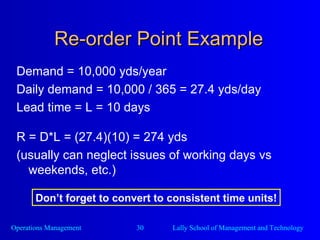

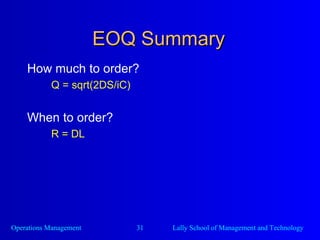

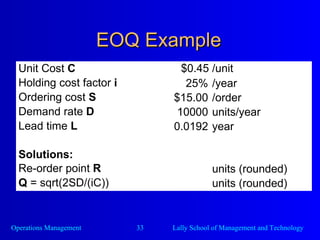

The document discusses inventory management concepts. It defines types of inventory like raw materials, work in process, and finished goods. It explains the difference between independent and dependent demand and how they are managed. There are reasons to hold inventory, like meeting demand variations, and reasons not to hold too much like carrying costs. The Economic Order Quantity (EOQ) model is introduced for determining how much and when to order to minimize total inventory costs based on demand, ordering costs, carrying costs, and lead times. Managers must find the optimal balance of ordering and carrying costs.