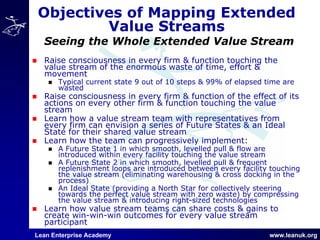

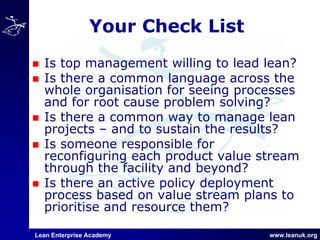

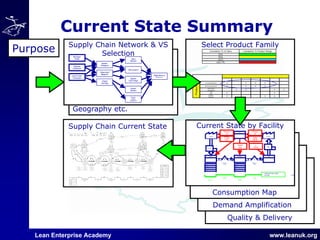

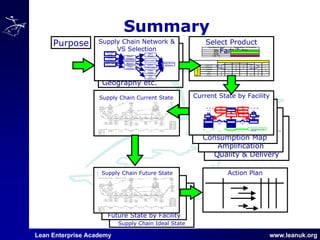

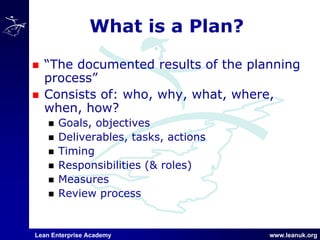

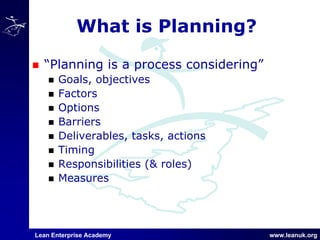

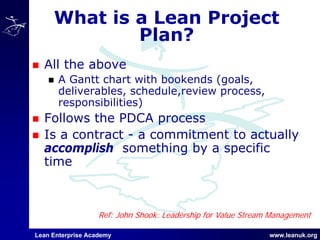

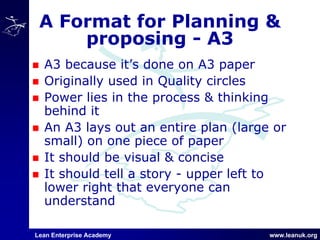

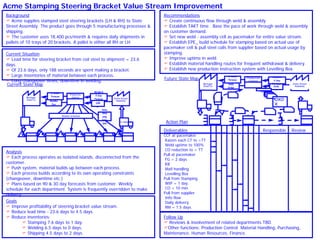

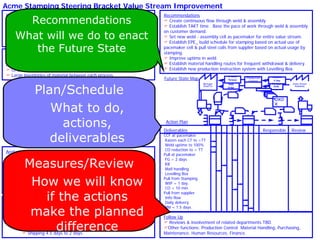

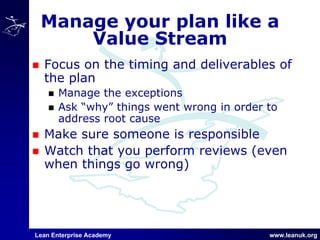

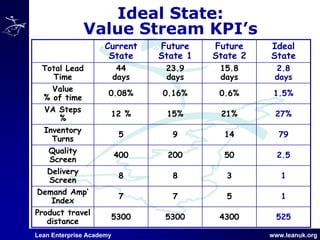

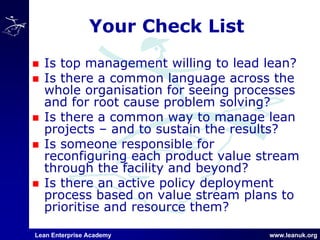

The document outlines the objectives and methodologies for creating effective value stream plans within supply chain management, emphasizing the significance of mapping value streams to reduce waste and improve efficiency. It highlights the need for cross-functional teams to envision and implement future states that allow for smooth pull and flow, ultimately aiming for an ideal state with zero waste. Additionally, it discusses planning processes, goal setting, and performance monitoring to ensure the sustainability of lean initiatives.