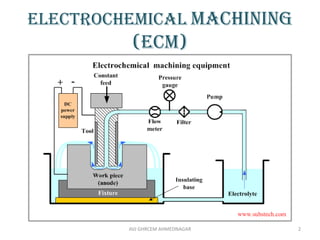

Electrochemical machining (ECM) is a process that uses the principle of reverse electroplating, where the tool acts as the cathode and the workpiece as the anode, to remove metal atom-by-atom through an electrochemical reaction in the presence of an electrolyte. The setup requires a DC power supply, work holding system, tool feed system, and an electrolyte supply system, with notable advantages such as high tool life and burr-free surfaces, but also disadvantages like high initial investment and power consumption. ECM is mainly applied in operations like die-sinking, drilling, and turbine blade manufacturing.