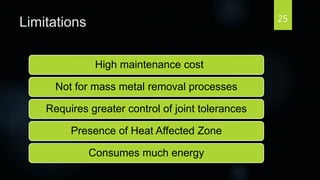

The document provides an overview of laser beam machining, detailing the principles of lasers and their applications in industrial processing. It describes various types of lasers, such as gas, solid-state, and excimer lasers, alongside their operational modes and uses in cutting and material removal. The advantages and limitations of laser machining are also discussed, highlighting its non-contact nature and energy consumption.