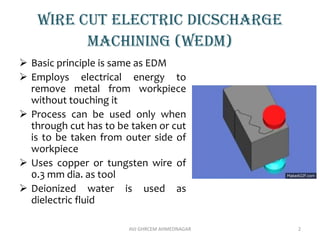

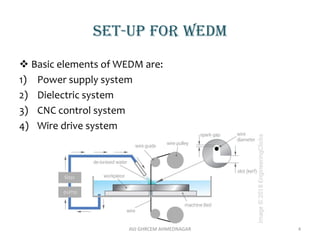

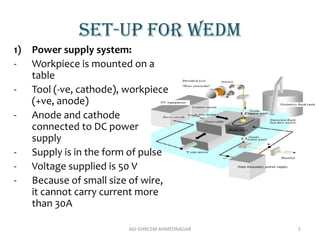

The document provides an overview of Wire Cut Electric Discharge Machining (WEDM), emphasizing its principles, setup, and operational parameters. Key components include a power supply system, dielectric system using deionized water, CNC control system, and wire drive system, with various controlling parameters influencing material removal rate and surface finish. The advantages include high precision and unattended operation, while disadvantages involve limitations on material types and depth of cut.