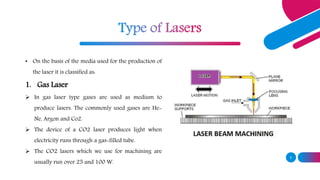

Laser beam machining is a non-conventional machining process that uses laser light to melt and vaporize materials, requiring three main components: a laser medium, a means of excitation, and an optical feedback system. It comes in various types, such as gas and solid-state lasers, and works by converting electrical energy to produce a focused laser beam that can cut and engrave materials with high precision. While it offers low wear and tear and the capability to work with a variety of materials, it has disadvantages like high initial costs, low production rates, and the need for skilled operators.