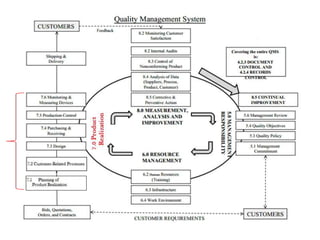

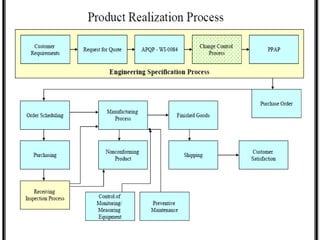

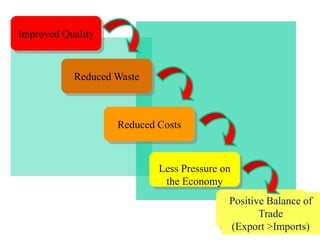

The document outlines the quality management processes of Bla Power Pvt. Ltd., focusing on customer-related processes, purchasing, production, and service provision. It emphasizes the importance of customer communication, purchasing product verification, and monitoring equipment calibration to ensure product quality and compliance with established requirements. The document also highlights the effects of product quality on customer satisfaction and economic performance.

![4/17/2014

7.0

PRODUCT

REALIZATION

Mr. Manoj Kumar Maharana

Sr. Engineer [Dept. of Electrical ]

BLA Power Pvt Ltd

1

BLA Power Pvt. Ltd BLA Power Pvt. Ltd](https://image.slidesharecdn.com/7-140417043217-phpapp02/85/ISO-Clause-No-7-Production-Realization-1-320.jpg)

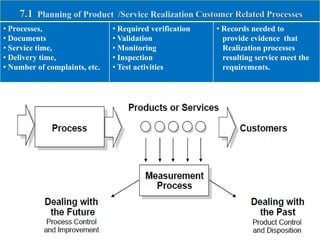

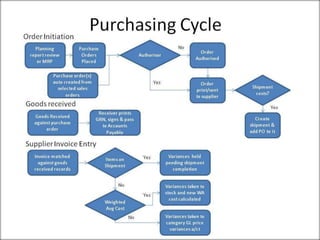

![7.2 Customer Related Processes

7.2.1

Determination Of

Requirements to

the Product

• Delivery activities & Post delivery activities such as

> Warranty provisions & Contractual Obligations

> such as Maintenance services.

> Recycling Or Final disposal.

• Statutory & Regulatory requirement applicable to product.

7.2.2

Review Of

Requirement

Related to the

Product/Services

The organization shall review the requirements related to product

[ submission of tenders, acceptance of contracts or orders, acceptance

of changes to contracts or orders ]

•Product requirements are defined

•Contract or order requirements differing from those previously

expressed are resolved.

•The organization has the ability to meet the defined requirements.

•Records should maintained of the results of the review & actions.

7.2.3

Customer

Communication

Determine and implement effective arrangements for communicating

with customers in relation to

•Product information

•Enquiries, contracts or order handling, including amendments,

•Customer feedback, including customer complaints](https://image.slidesharecdn.com/7-140417043217-phpapp02/85/ISO-Clause-No-7-Production-Realization-6-320.jpg)

![Special Thanks

• for Guidance

Mr. Kalpesh Goswami

Sr. Manager [ Dept. Of Inst. ]

Acknowledgement [suggested reading]

• ANSI/ASQ 9000:2000 Quality Management Systems – Fundamentals and Vocabulary

• ANSI/ASQ 9001:2000 Quality Management Systems – Requirements, December

13,2000

• Quality Management System manual Doc No: BLAPOWER/M/QMSM/01

14](https://image.slidesharecdn.com/7-140417043217-phpapp02/85/ISO-Clause-No-7-Production-Realization-14-320.jpg)