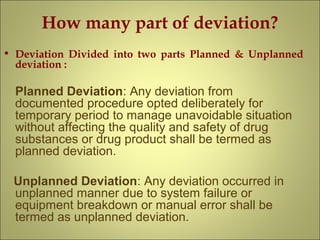

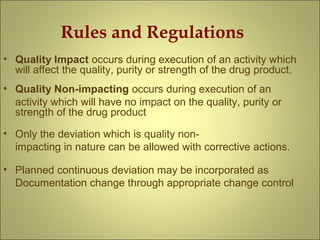

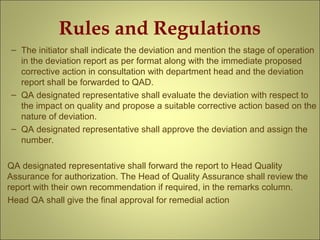

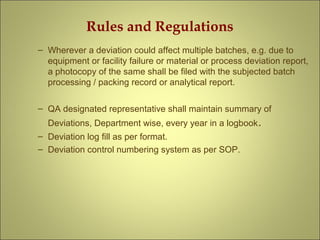

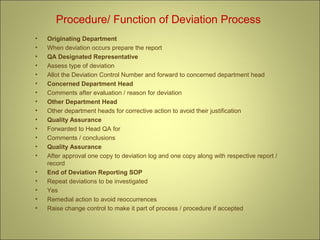

This document outlines procedures for handling deviations from standard operating procedures in a cGMP environment. It defines deviations as planned or unplanned activities that differ from specified procedures. Planned deviations are deliberate temporary changes that don't affect quality, while unplanned deviations result from failures or errors. The procedures describe rules for documenting deviations, evaluating their quality impact, approving corrective actions, and filing reports. Deviations are assigned a control number and approved by quality assurance to ensure proper handling. Repeated deviations must be investigated and corrective actions taken to prevent reoccurrences.