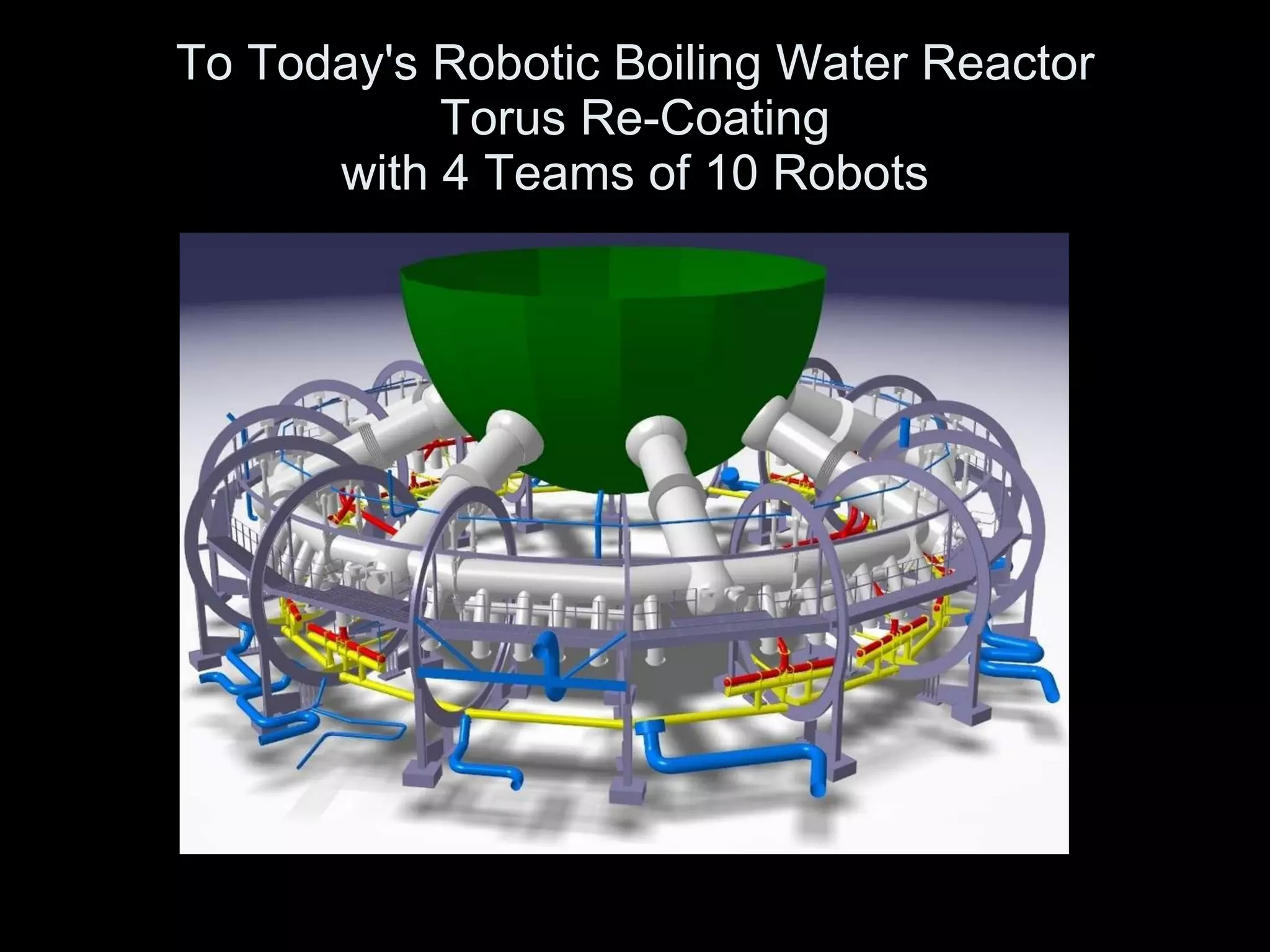

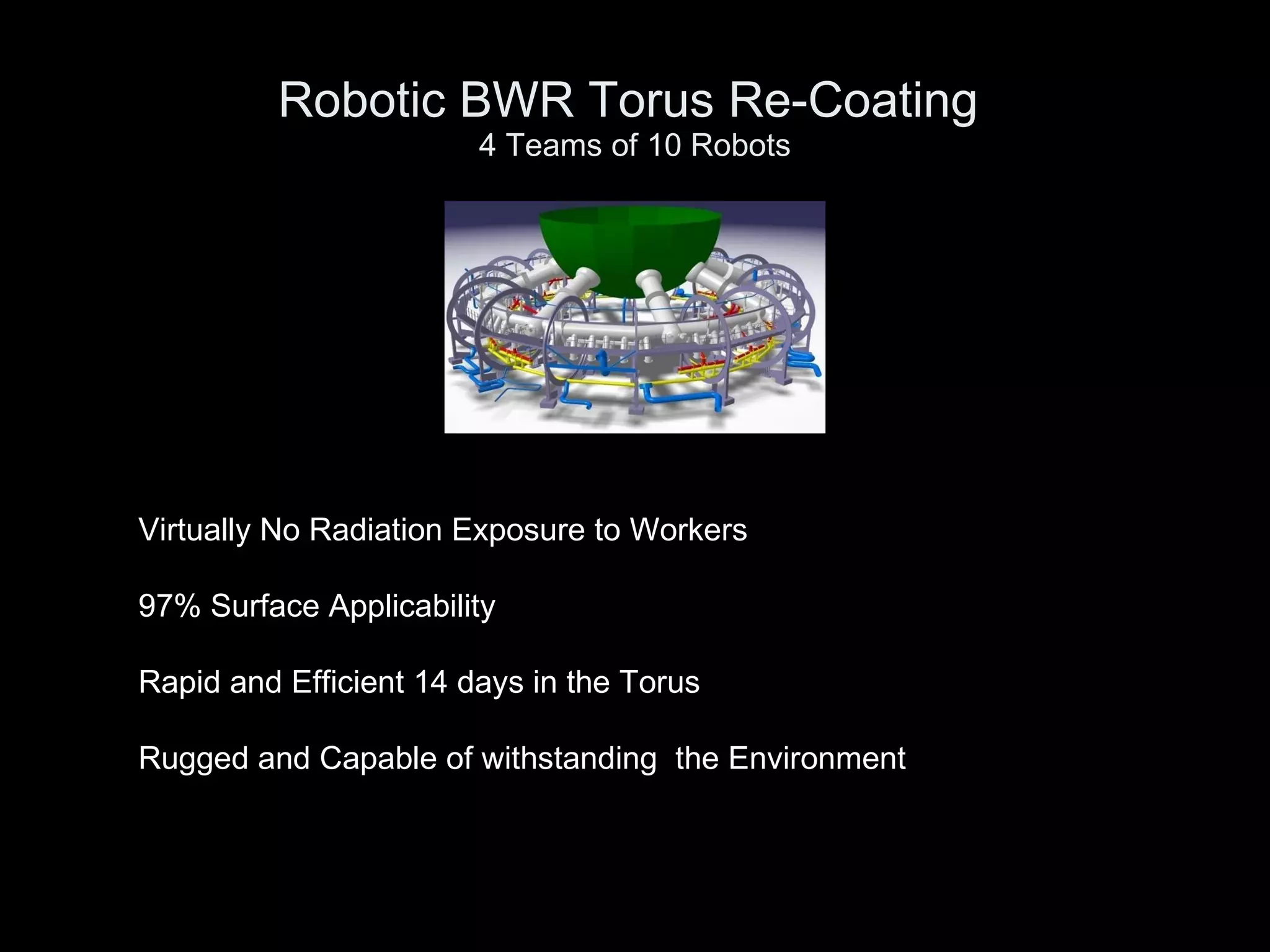

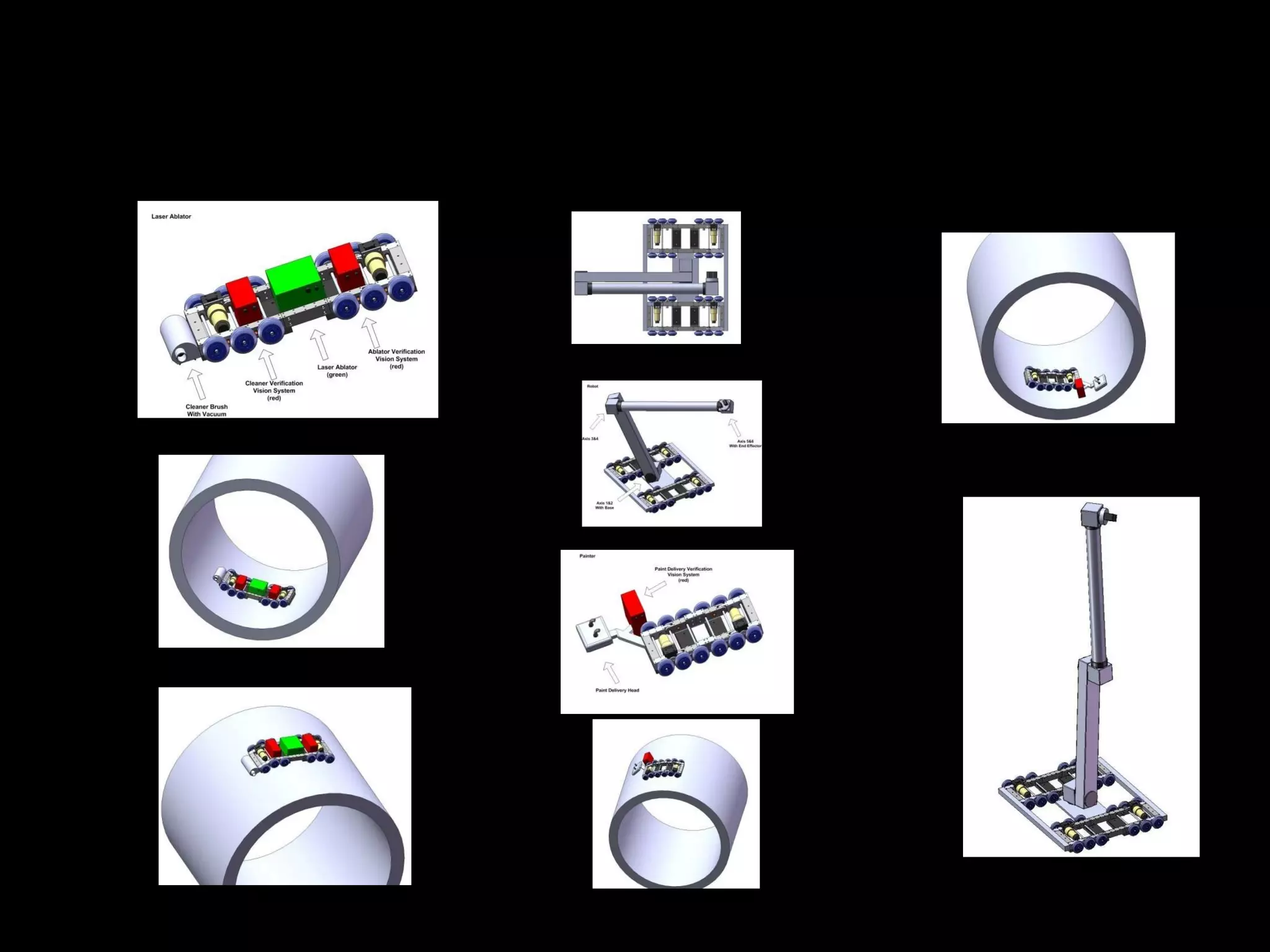

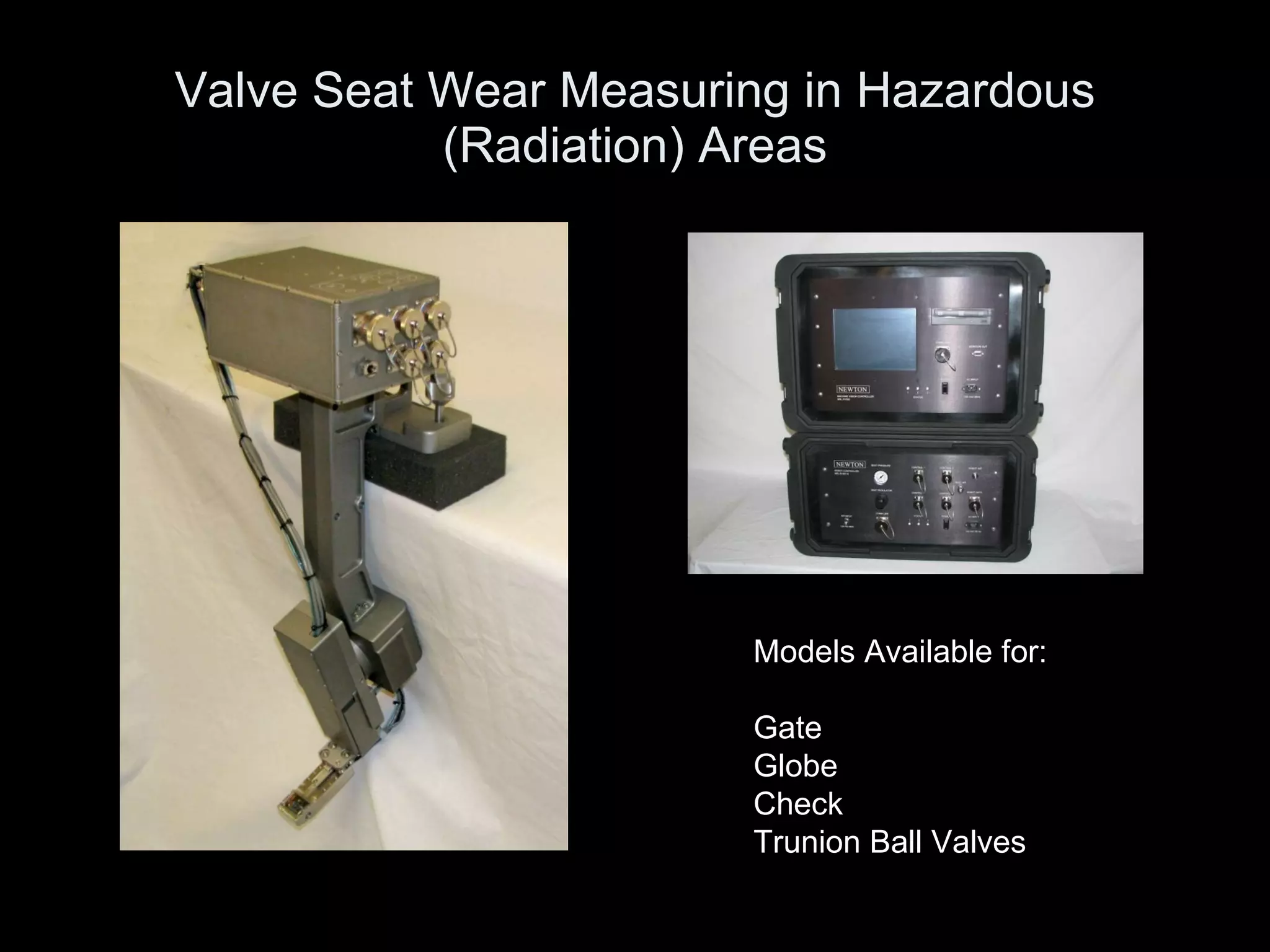

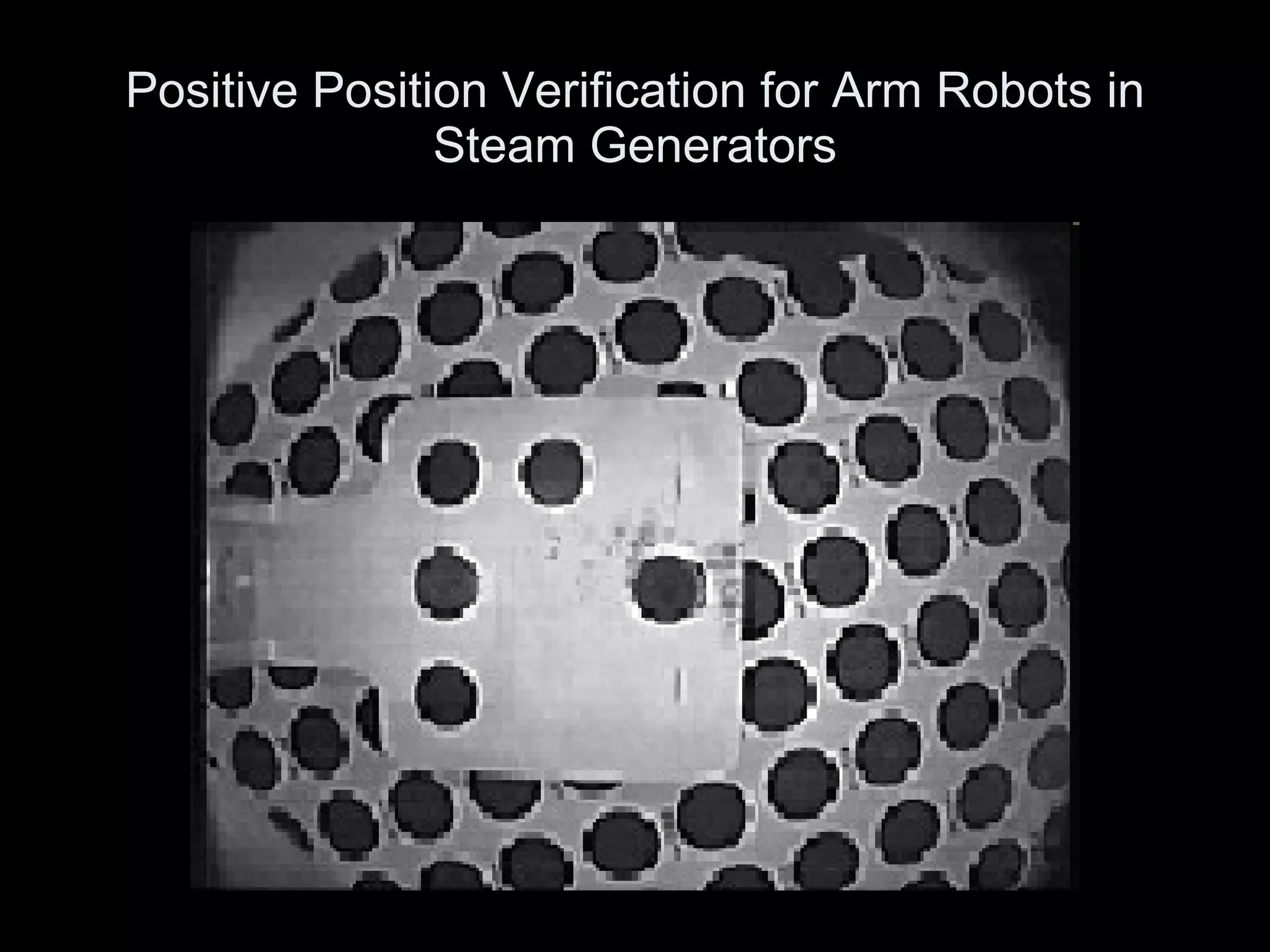

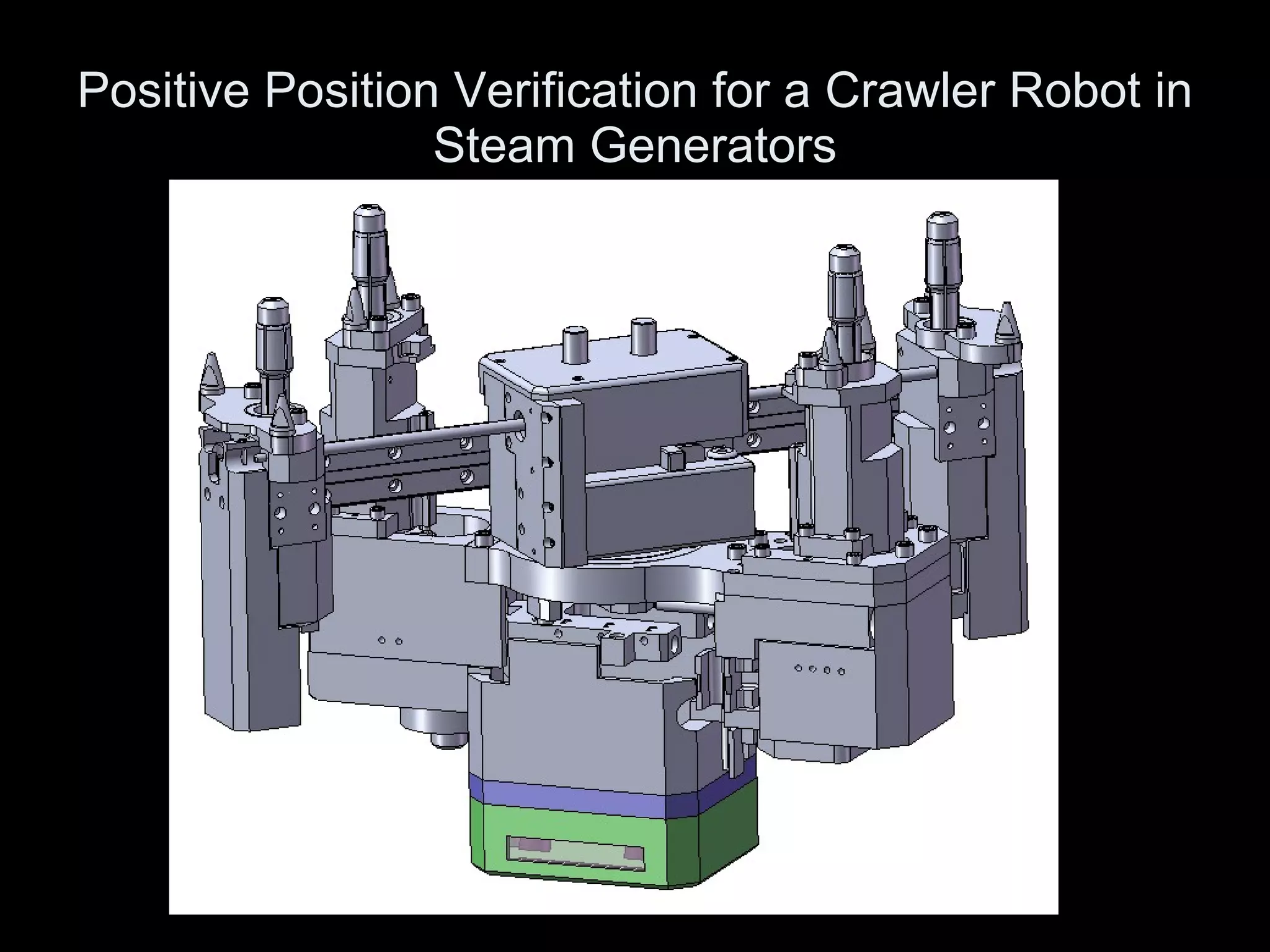

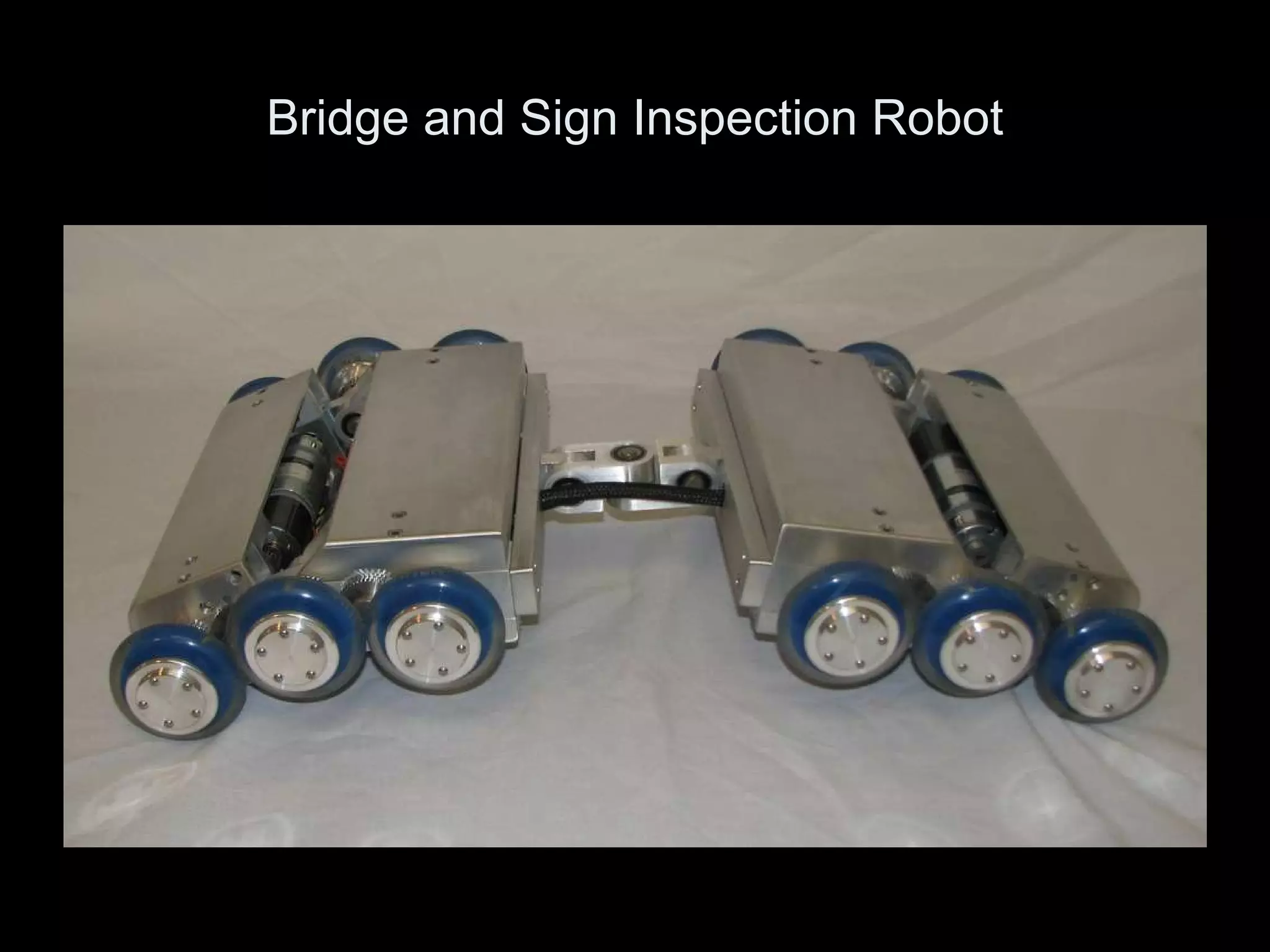

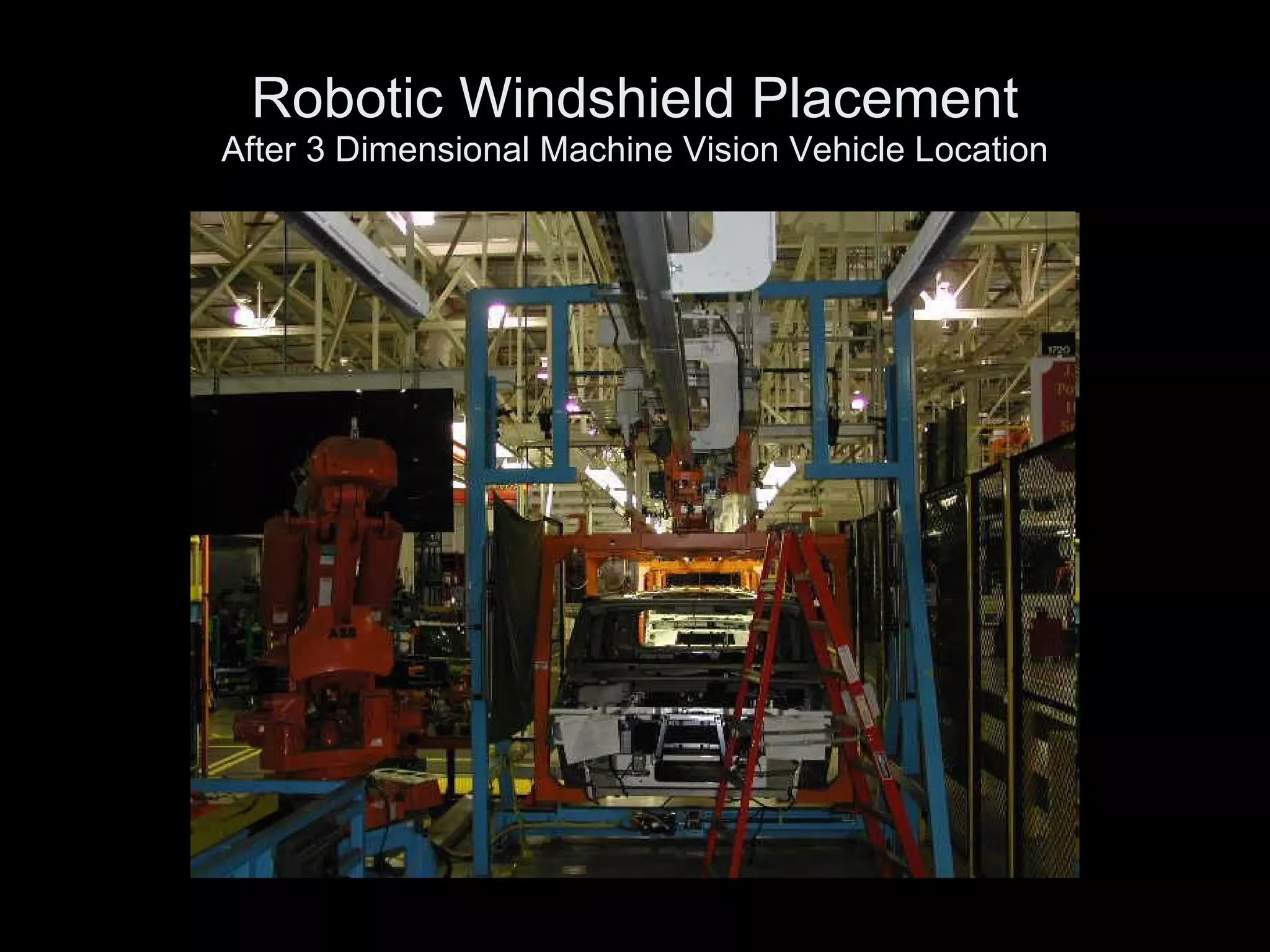

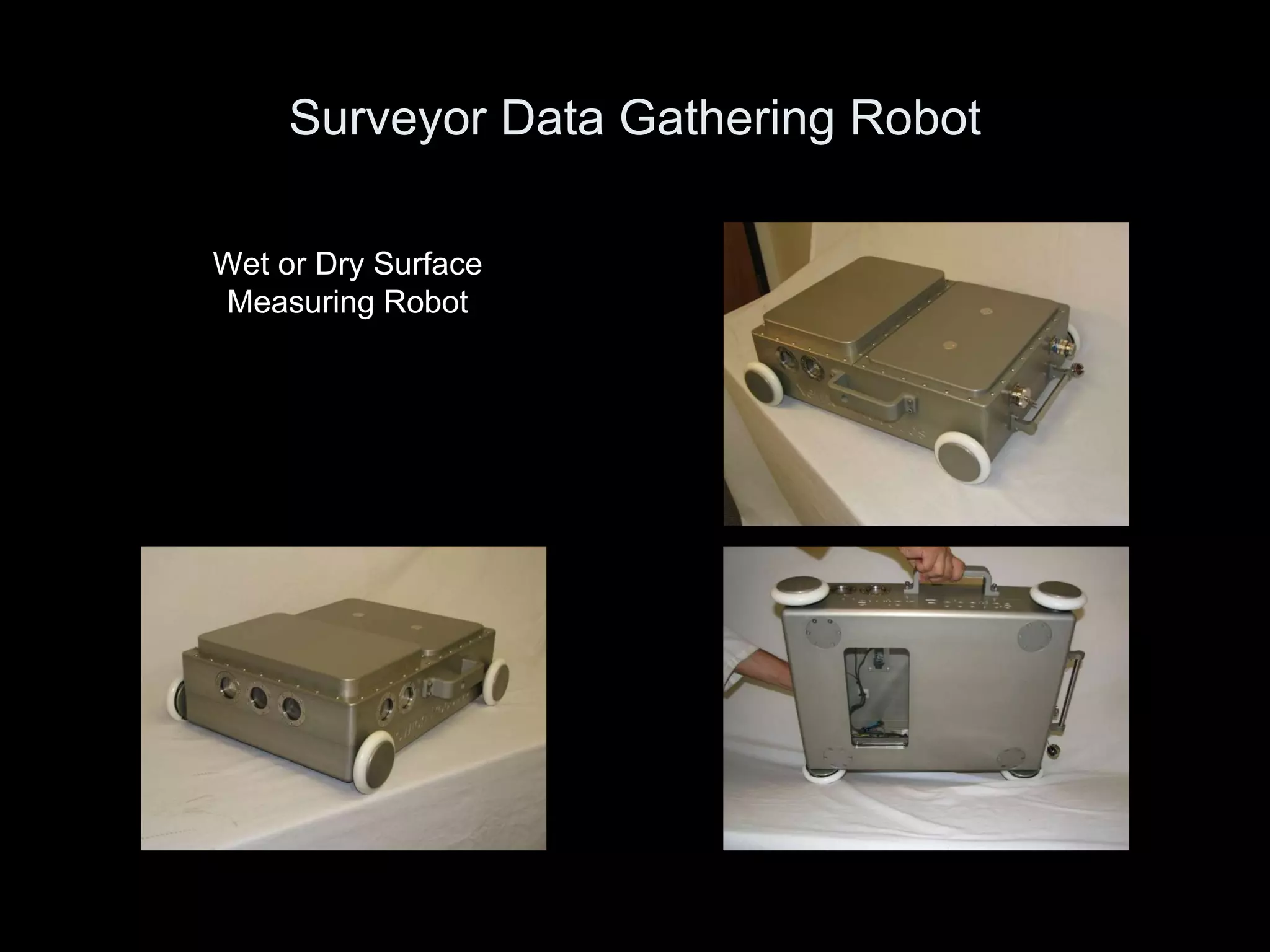

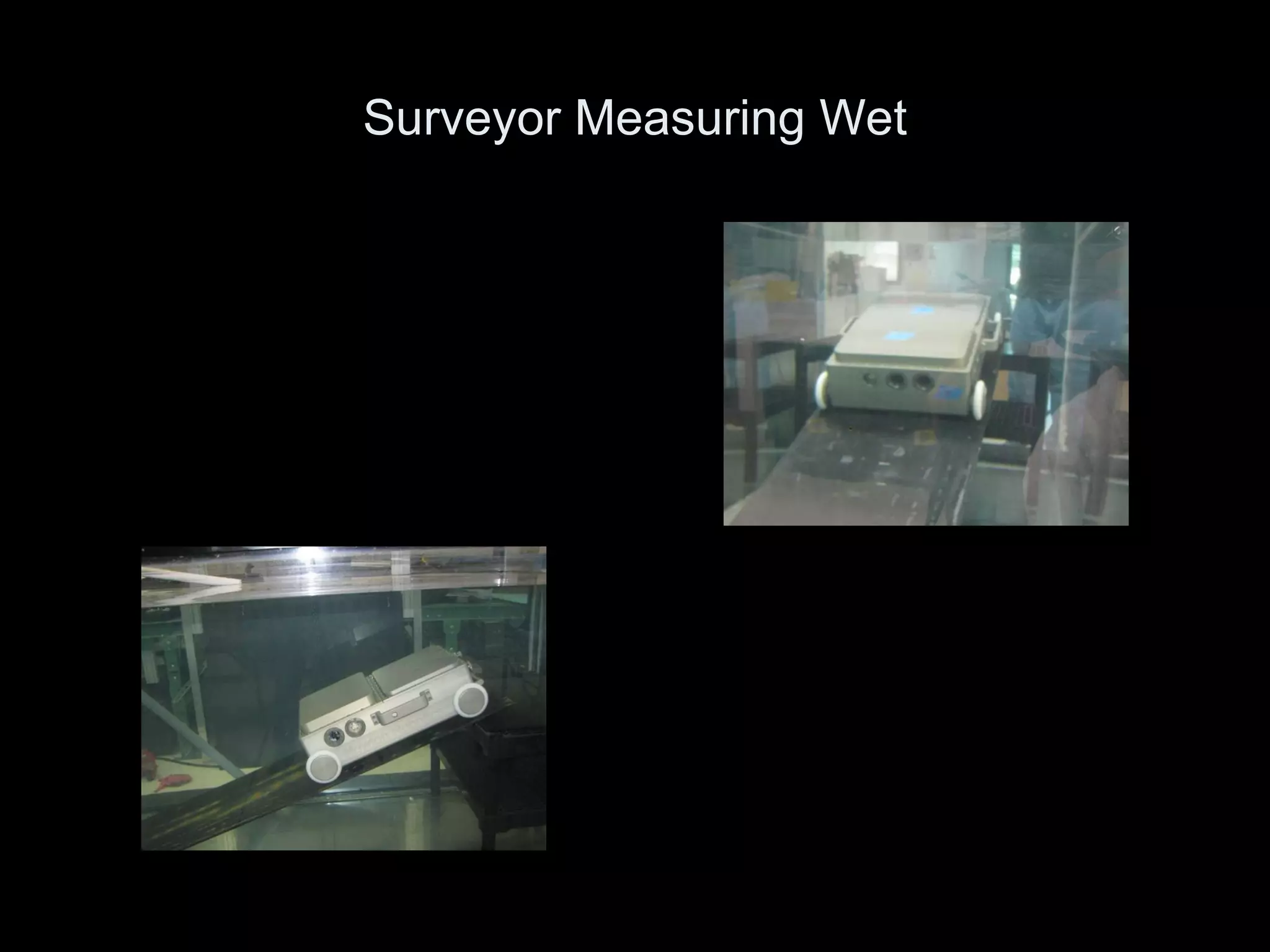

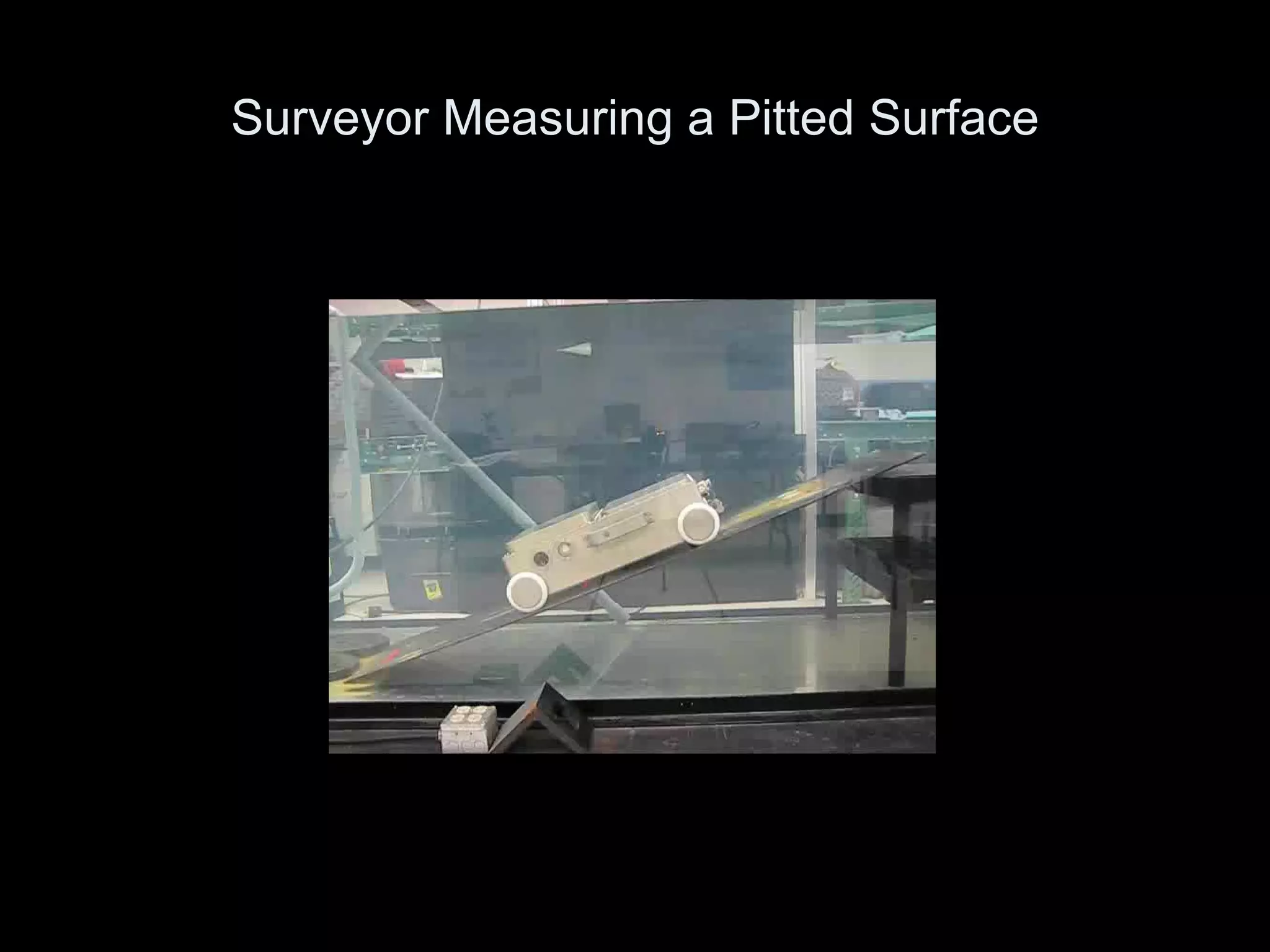

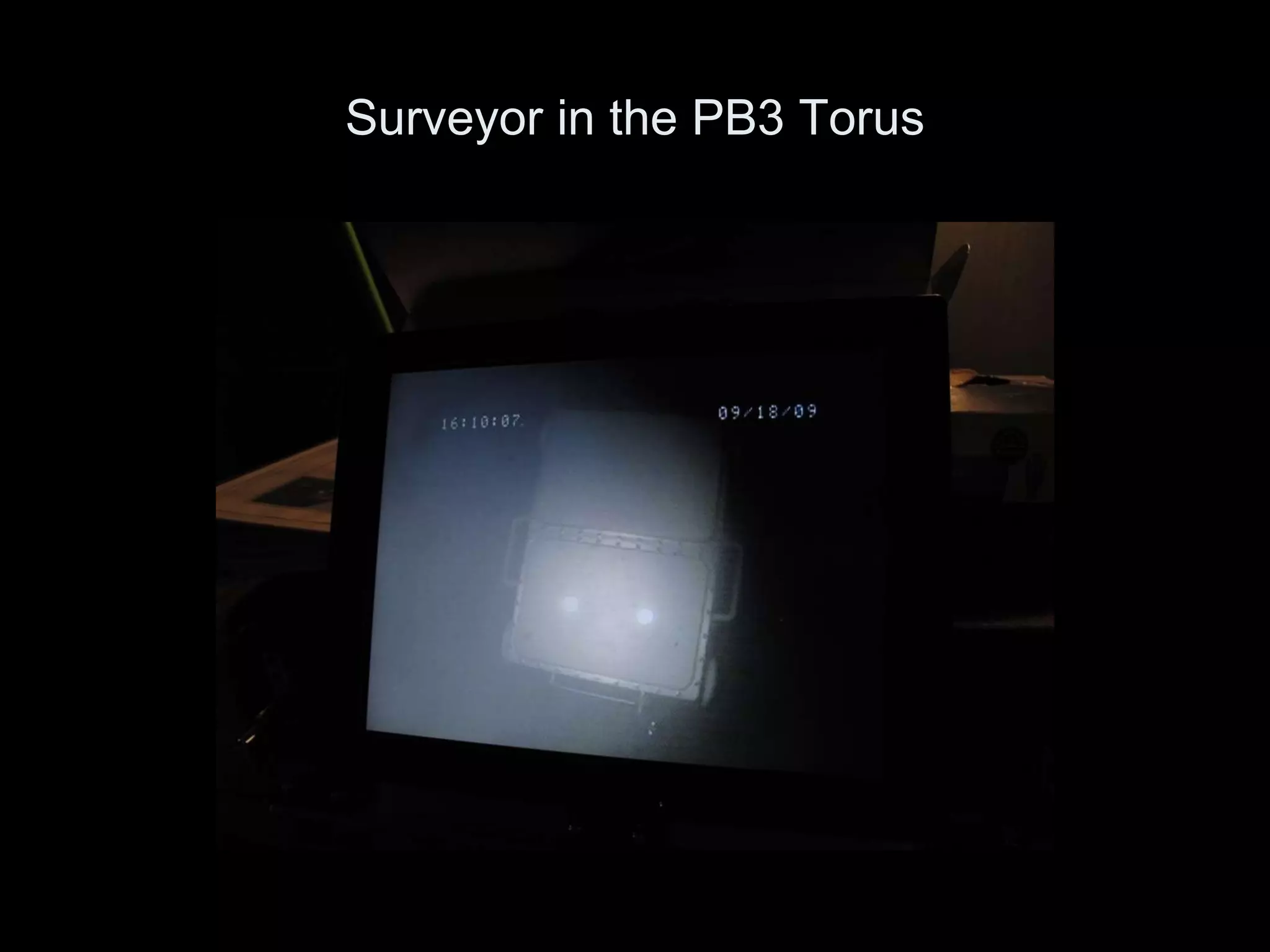

Newton Robotics, founded as an offshoot of MIT in 1990, specializes in integrating machine vision with robotics to enhance automation across various industries. They design and manufacture their own software and hardware, deploying over 15,000 systems globally for innovative applications such as robotic surgery, underwater navigation, and inspection in hazardous environments. Their projects have been pioneering worldwide, demonstrating significant advancements in robotic capabilities and efficiency.