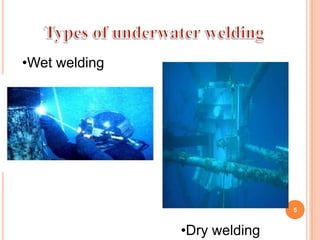

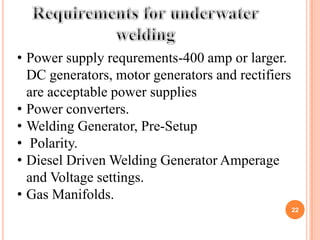

The document discusses underwater welding technology. It describes how underwater welding was first developed by the British Admiralty and then special waterproof electrodes were created. It discusses the different types of underwater welding including wet welding, dry welding using hyperbaric chambers, and different habitat sizes. It outlines the challenges of underwater welding including costs and equipment needs. It also discusses the welding processes, necessary equipment, safety considerations, and developing automation trends in the field.