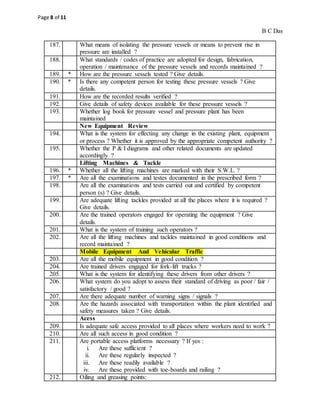

The document is a checklist for auditing general safety, health, and emergency preparedness at an industrial organization. It contains 195 questions across various categories including health and safety policy, safety organization structure, accident reporting, safety inspections, training, hazard identification, fire protection, emergency preparedness, and more. Many questions are marked with an asterisk to indicate they require a yes or no answer. The extensive checklist aims to evaluate all aspects of the organization's safety management system and emergency response capabilities.