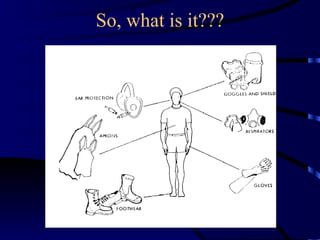

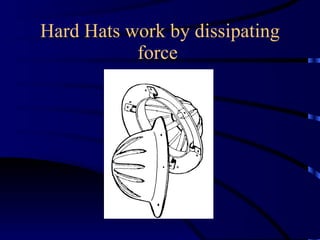

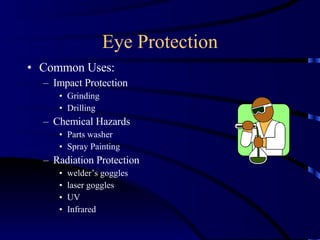

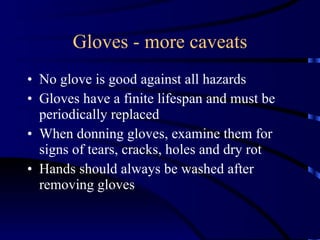

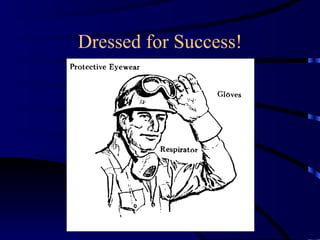

The document provides an overview of personal protective equipment (PPE), defining it as essential devices to protect workers from various workplace hazards. It emphasizes the need for thorough risk assessments to determine the appropriate PPE, highlighting that it should be a last resort when other safety measures fail. Also discussed are the types of PPE, usage guidelines, and the responsibilities of both employers and workers regarding the availability and maintenance of PPE.