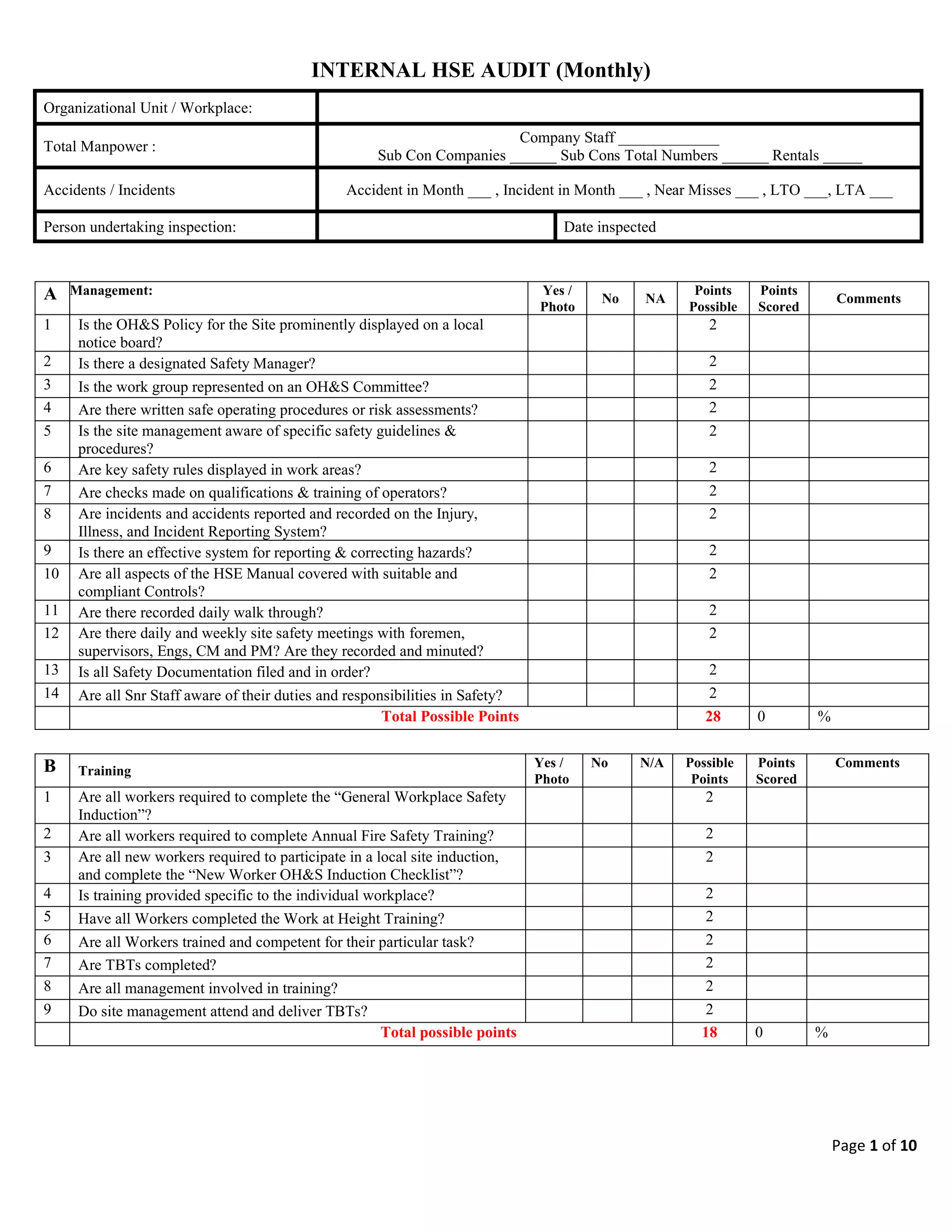

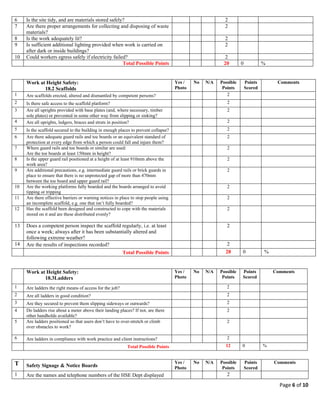

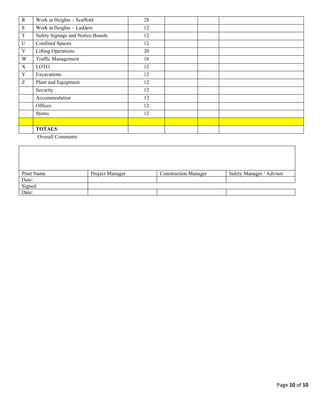

This document provides an internal health, safety, and environment (HSE) audit checklist for a monthly organizational audit. It contains over 200 questions across 20 categories related to HSE policies, training, the work environment, amenities, housekeeping, special work procedures, hazards, equipment, and other factors. The audit is intended to evaluate compliance with HSE standards and identify any nonconformities requiring corrective action. No audit results are provided in the sample document.