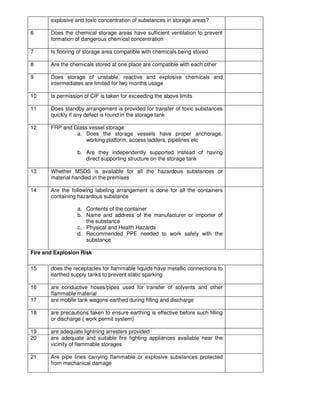

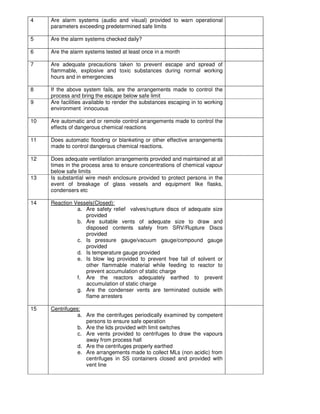

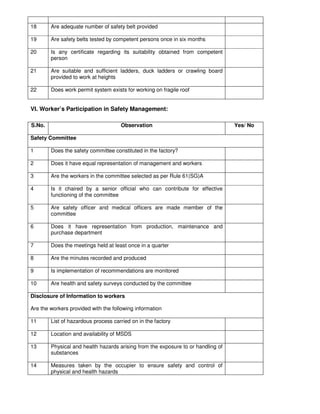

The inspection checklist summarizes information about a factory inspection. It includes sections on general information about the factory, safety provisions, fire prevention and control, welfare amenities, health provisions, occupational health centres, and other provisions like record keeping. For hazardous factories, it has additional sections on hazard identification and risk reduction, safety in chemical storage and handling, process safety, and equipment safety. The checklist involves checking over 100 different points to assess compliance with factory safety and health standards.