1. Lock out tag out (LOTO) procedures are used to safeguard workers during service or maintenance of machines and equipment by isolating hazardous energy sources.

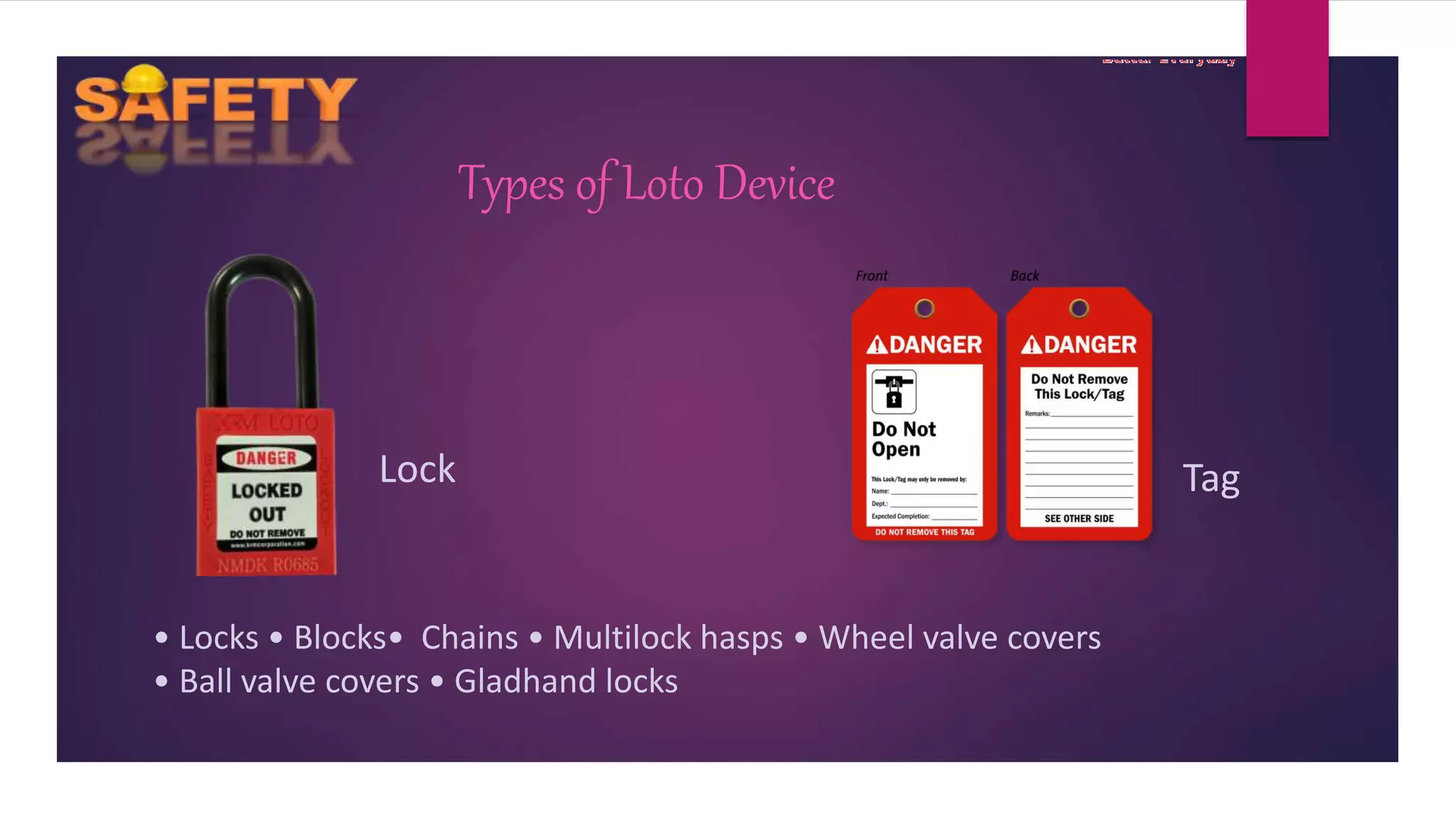

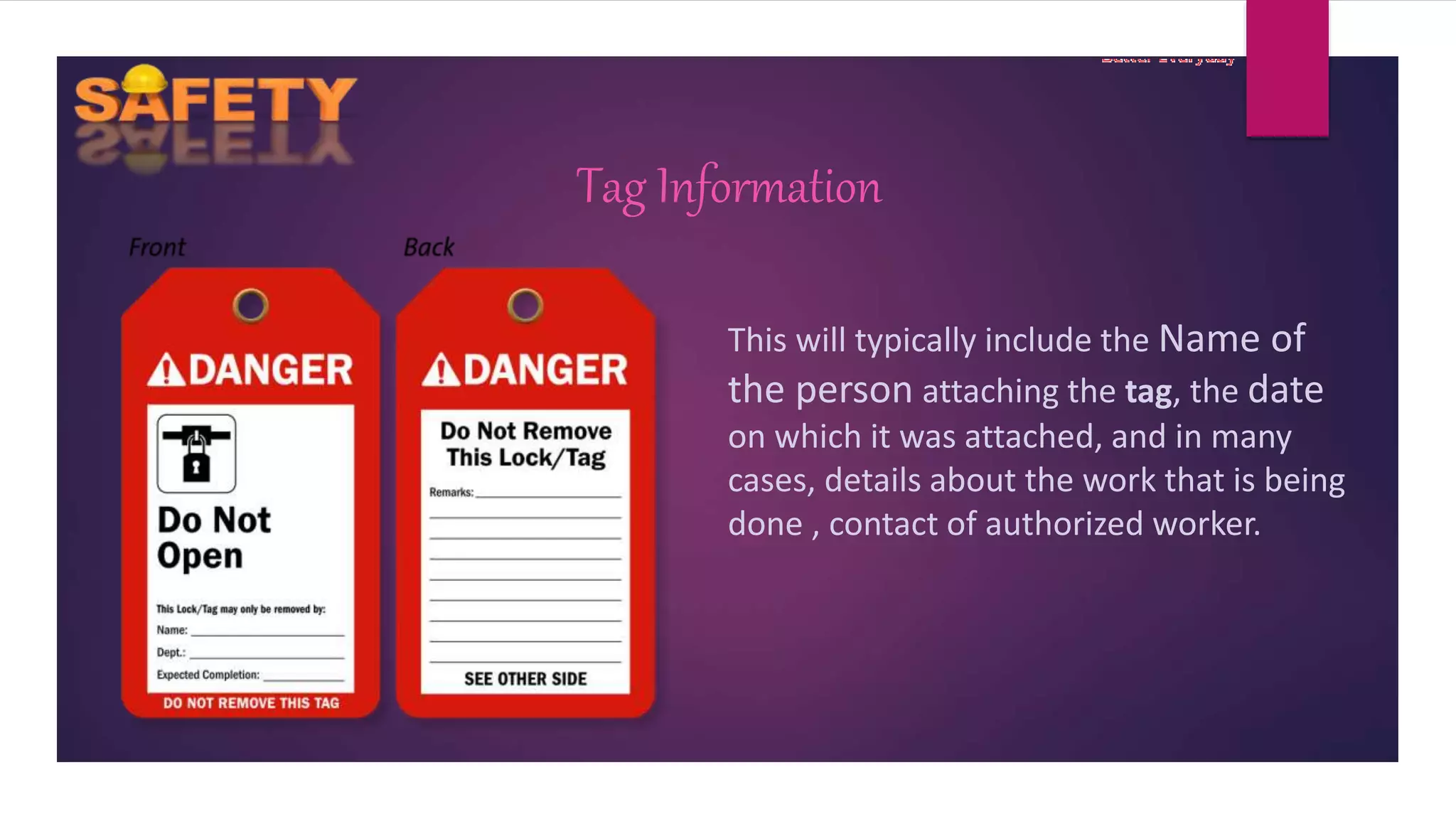

2. LOTO is required when employees could be harmed by equipment startup or release of stored energy while working on or near machines. It involves shutting down and isolating equipment, then locking out energy sources and attaching warning tags.

3. Proper LOTO procedures include preparing for the job, shutting down and isolating equipment, applying locks and tags, relieving stored energy, verifying isolation, getting approval before re-energizing, informing workers, and periodic inspections.