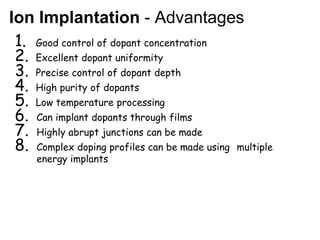

1. Ion implantation involves ionizing dopant atoms, accelerating them into a beam, and embedding them into a wafer's crystalline structure. This allows for precise doping control without high temperatures.

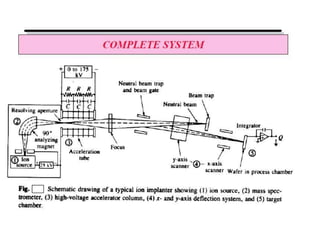

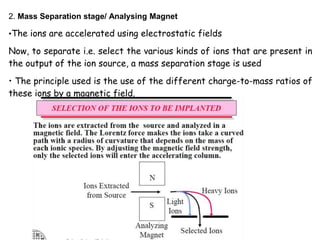

2. An ion implanter consists of an ion source, mass analyzer, accelerator, and target chamber. The ion source produces dopant ions which the mass analyzer selects before acceleration into the target wafer.

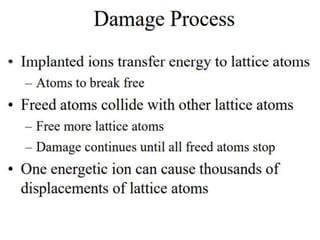

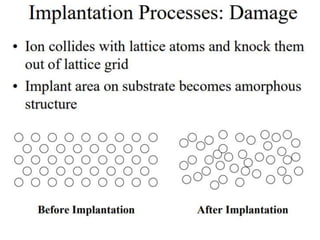

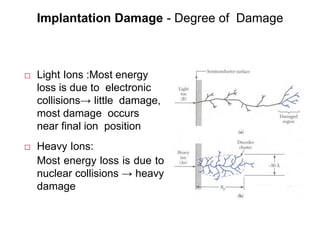

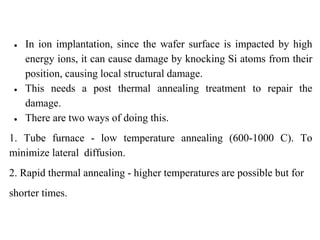

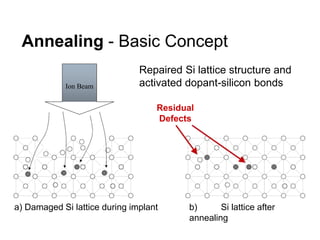

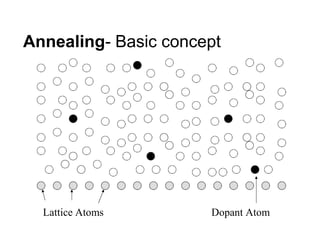

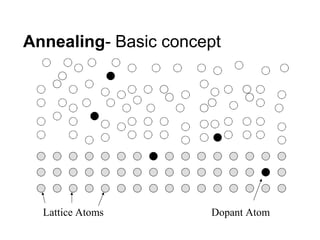

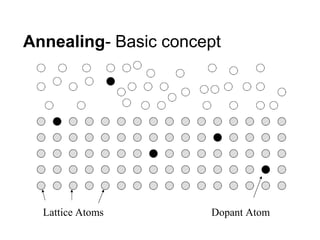

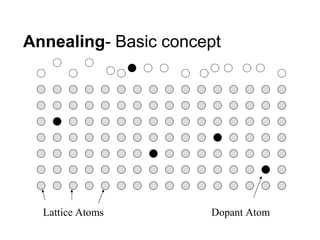

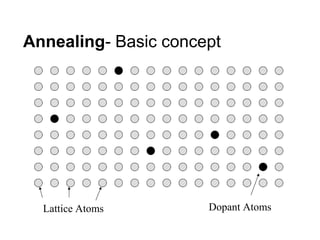

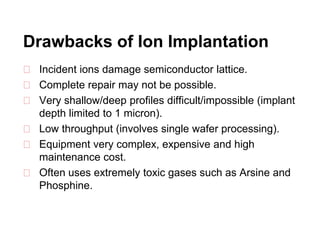

3. Implanted ions can damage the wafer's crystal structure, requiring subsequent annealing to activate the dopants and repair damage. Precise annealing is needed to minimize dopant diffusion.

![● The magnetic field of the analyzer is chosen such that only ions

with the desired charge to mass ratio can travel through

without being blocked by the analyzer walls.

● A magnetic field B is applied normal to the path of ions with

charge q and velocity v

● The force on the ions is given by F=qvB and the ions move in a

circular path of radius r and there is a centripetal force

F=M v2/R

● Therefore, qvB= M v2/R [velocity v is unchanged]

And R = Mv/qB ------------------------------------(1)

● Now for an ion accelerated through a potential Vext the velocity

is given by:

M v2 /2 = qVex , from where we get v as:](https://image.slidesharecdn.com/ionimplantation1-220724175850-48dd11b3/85/IONIMPLANTATION-1-pptx-13-320.jpg)

![Most semiconductors are crystalline and have highly anisotropic properties. Because of the

ordered arrangement of lattice atoms, ions can penetrate more deeply into the crystal along

major axis and planes. This phenomenon is called channeling effect. To avoid channeling,

ion implantation is often carried out with an ion beam misoriented from the major axis by an

angle of at least 7 to 10 . Both Si and GaAs behave nearly as an amorphous solid when a

misoriented beam is used.

Channeling Effect

Fig. channeling effect

Ref-IcengB1

Ref pdf : implant-2[1]

Not isotropic.

= Having propertiesthat differ according to the direction of

measurement.

amorphous solid=A noncrystalline solid with nowell-defined

ordered structure.](https://image.slidesharecdn.com/ionimplantation1-220724175850-48dd11b3/85/IONIMPLANTATION-1-pptx-20-320.jpg)