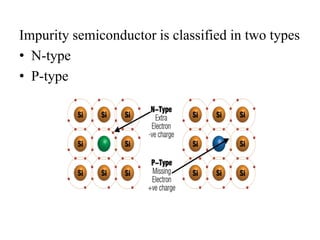

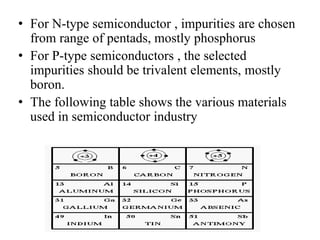

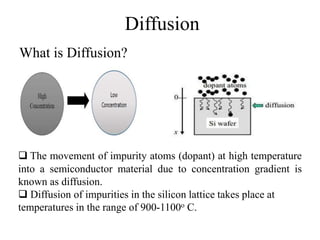

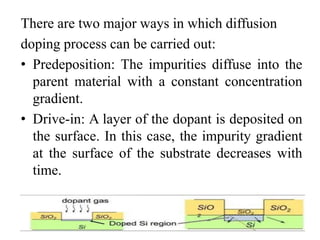

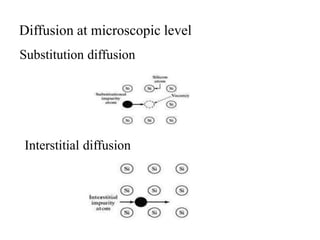

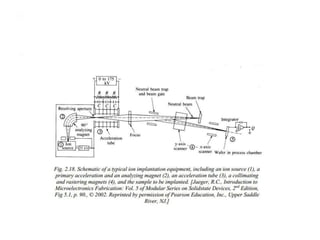

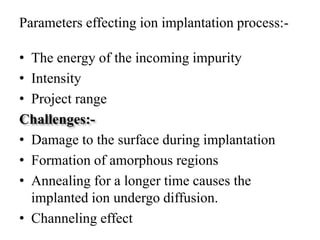

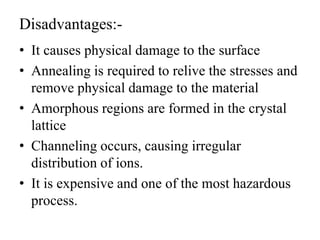

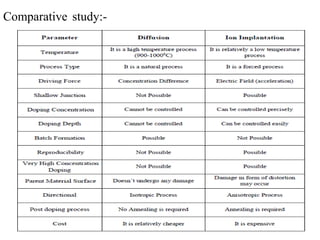

This document discusses semiconductor doping techniques used in the electronics industry. It describes intrinsic and extrinsic semiconductors and the two main types of doping: n-type and p-type. The two major doping techniques discussed are diffusion and ion implantation. Diffusion involves moving dopant atoms into the semiconductor through heating, while ion implantation accelerates dopant ions to implant them into the surface. Both techniques have advantages and disadvantages, with diffusion causing less damage but having less control over depth and concentration. Ion implantation offers more precise control but requires annealing to repair surface damage.

![References

1. J D Plummer, M D Deal and P B Griffin, “Silicon VLSI Technology: fundamentals,

practice and modelling”, Pearson Edu. Inc., 2001

2. Razeghi and Manijeh, “Technology of Quantum Devices”, Springer, 2010

3. Bose D.N., “Semiconductor Material and Devices”, New Age Publishers, 2012

4. F.G, Tseng, “IC Fabrication Process 2: Diffusion, Ion Implantation, Film Deposition,

Interconnection and contacts”. Lecture conducted from National Tsing Hua University,

Taiwan.

5. John (2010, June 1), “Diffusion of impurities for IC fabrication”

6. R.C. Jaeger (vol.5), Introduction to Microelectronic fabrication, Pearson Education

Inc., New Jersey,USA ,2002

7. Advancements in ion implantation Modelling for Doping of Semiconductors, Sivaco,

Inc. Available [Online] http://www.silvaco.com/content/kbase/ion_implantation.pdf

8. Plummer D. James, Deal Michael , Griffin D. Peter, “Silicon VLSI Technology:

Fundamentals, Practise and Modelling”, Prentice Hall , 2000.

9. Gupta Dushyant (2011) , “Plasma Immersion Ion Implantation Process Physics and

Technology", International Journal of Advancements in Technology.](https://image.slidesharecdn.com/presentation-project6-161120205613/85/Presentation-project6-21-320.jpg)