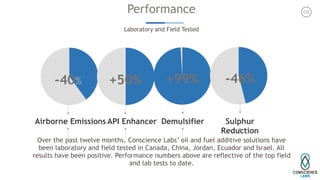

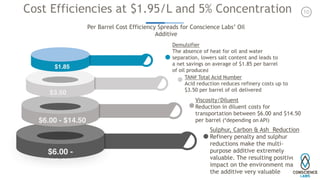

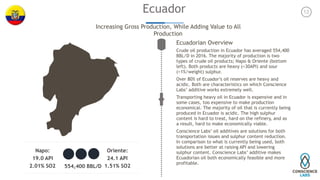

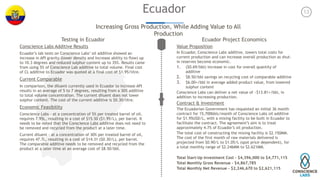

Conscience Labs provides additive solutions to improve crude oil and fuel quality. Their additives increase API gravity and decrease sulfur content in crude oil, improving fuel performance and reducing emissions. They have had successful testing of their products in laboratories and fields in multiple countries, showing improvements in metrics like API gravity, sulfur reduction, and emissions reductions. Conscience Labs is currently in discussions with potential partners in countries like Ecuador, Jordan, and Canada to implement larger-scale pilots and contracts for their additive solutions.