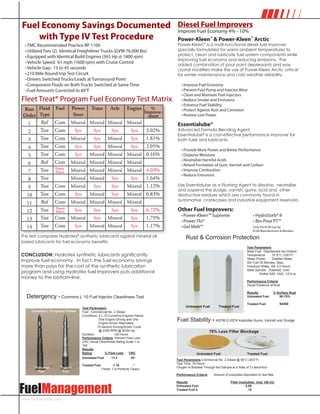

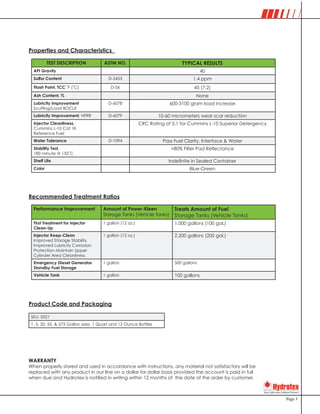

This document summarizes the results of a study testing the effects of Hydrotex synthetic lubricants versus mineral oil-based lubricants on fuel economy. The study found that the Hydrotex lubricants improved fuel economy by over 5%, which more than pays for the cost of the synthetic lubrication program. It also reduced emissions. A separate study on diesel fuel additives found they improved fuel economy by 4-10% and reduced particulate matter by up to 71% and other emissions. The additives were also found to clean fuel injectors and fuel systems.