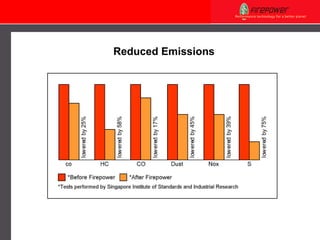

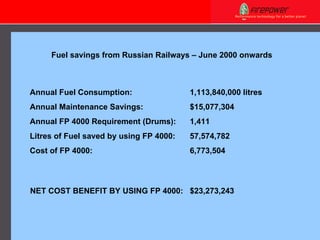

Firepower is a company established in 1990 that supplies fuel and oil conditioning technology. Their products are used to improve fuel efficiency, reduce emissions, prevent engine wear, and increase engine life. Firepower leads in developing solid and liquid fuel conditioners that have achieved international credibility through superior performance and efficiency gains.