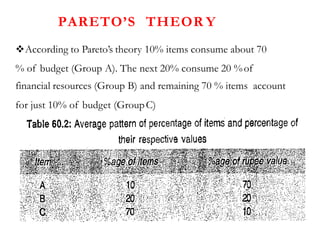

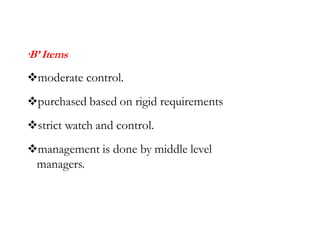

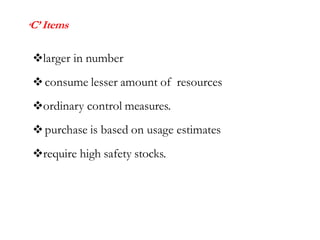

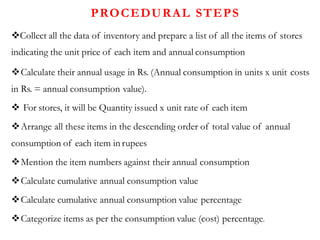

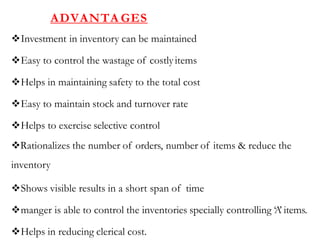

This document discusses material management and inventory control in nursing. It defines inventory as raw materials, parts, subassemblies, and finished products held prior to use. Maintaining proper inventory is important to ensure uninterrupted supplies and protect against uncertain demand. Methods of inventory control include two bin systems, buffer stocks, lead times, ABC analysis, VED analysis, and FSN analysis to classify items based on usage. The nurse manager plays a key role in ensuring adequate supplies, quality, storage, audits, and educating staff on proper material usage.