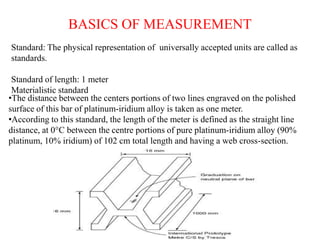

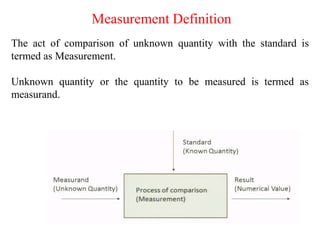

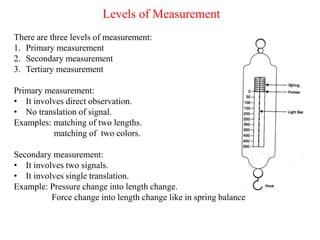

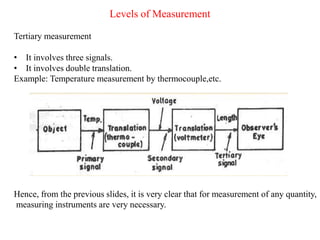

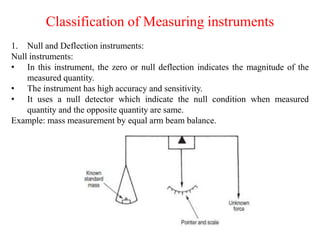

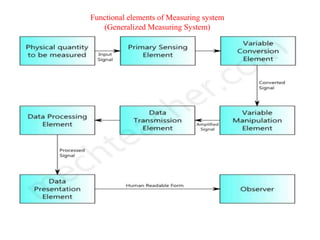

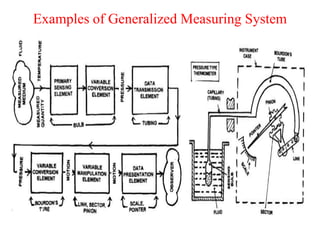

This document provides an introduction to measurement and metrology. It discusses the basics of measurement including defining standards of units such as length, time, current and temperature. There are four categories of standards based on accuracy from primary to working standards. Measurement involves comparing an unknown quantity to a standard. There are direct and indirect methods of measurement. Metrology includes theoretical and practical problems related to measurement and establishes measurement standards. The three types of metrology are scientific, industrial, and legal.