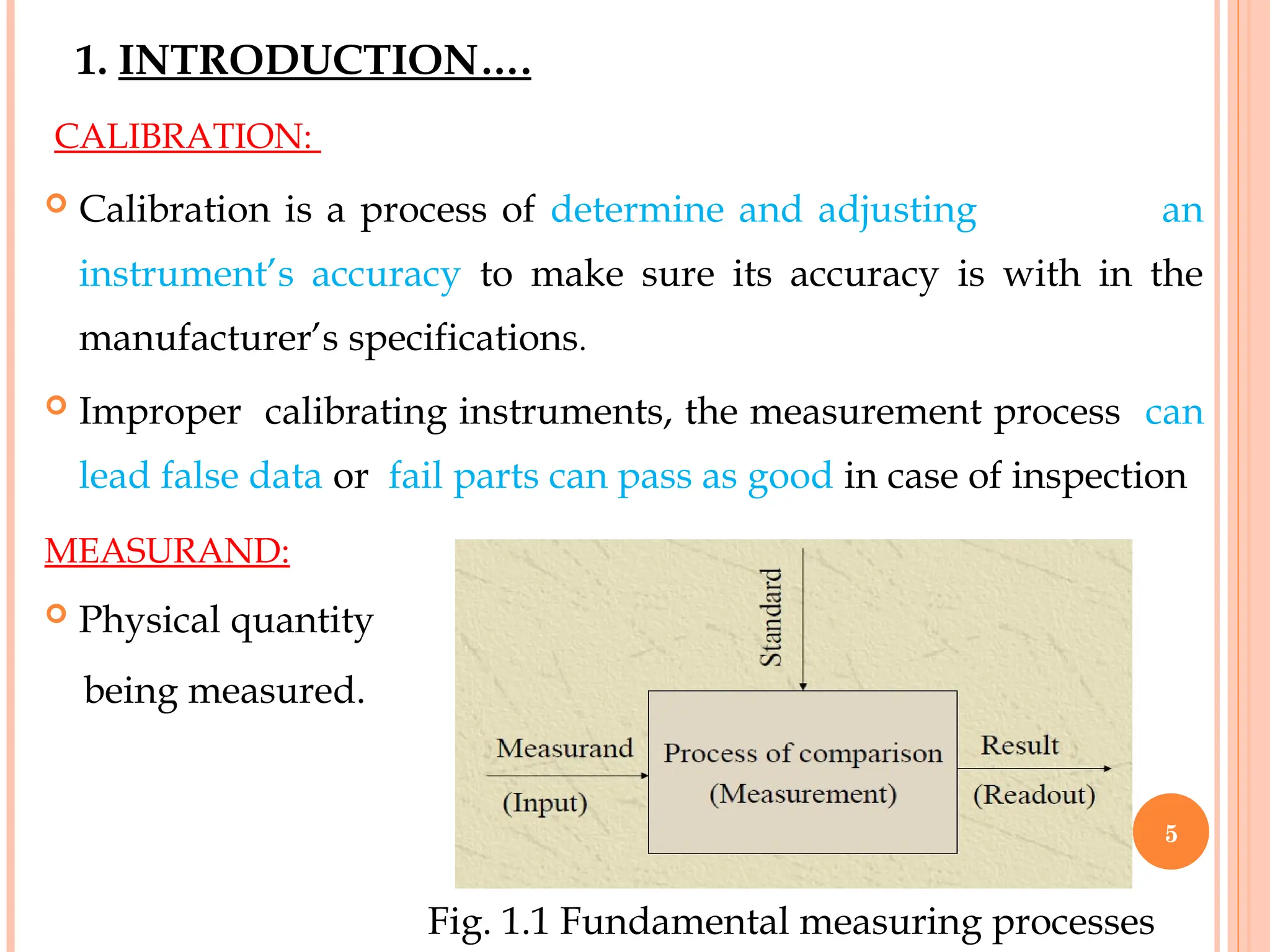

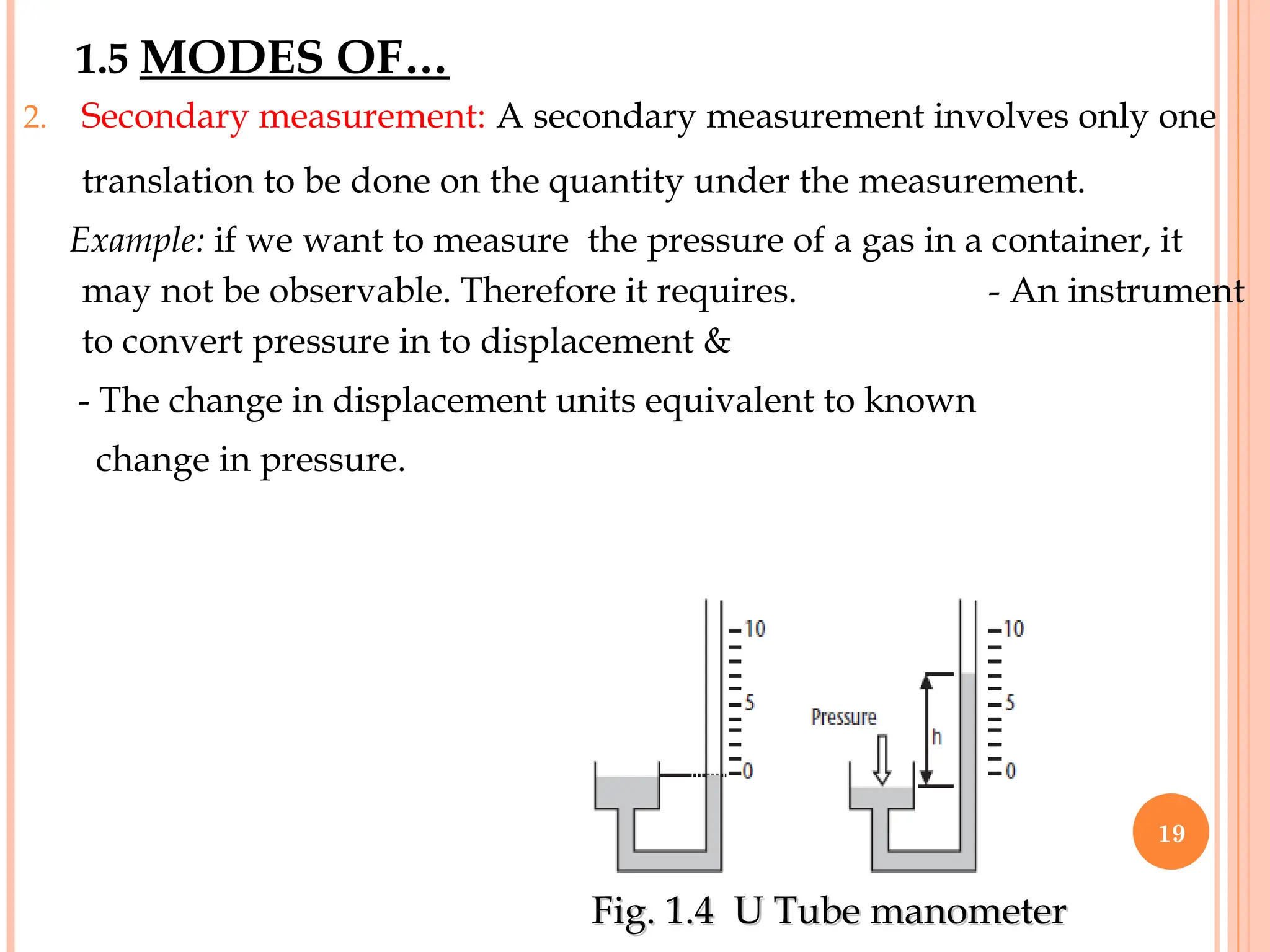

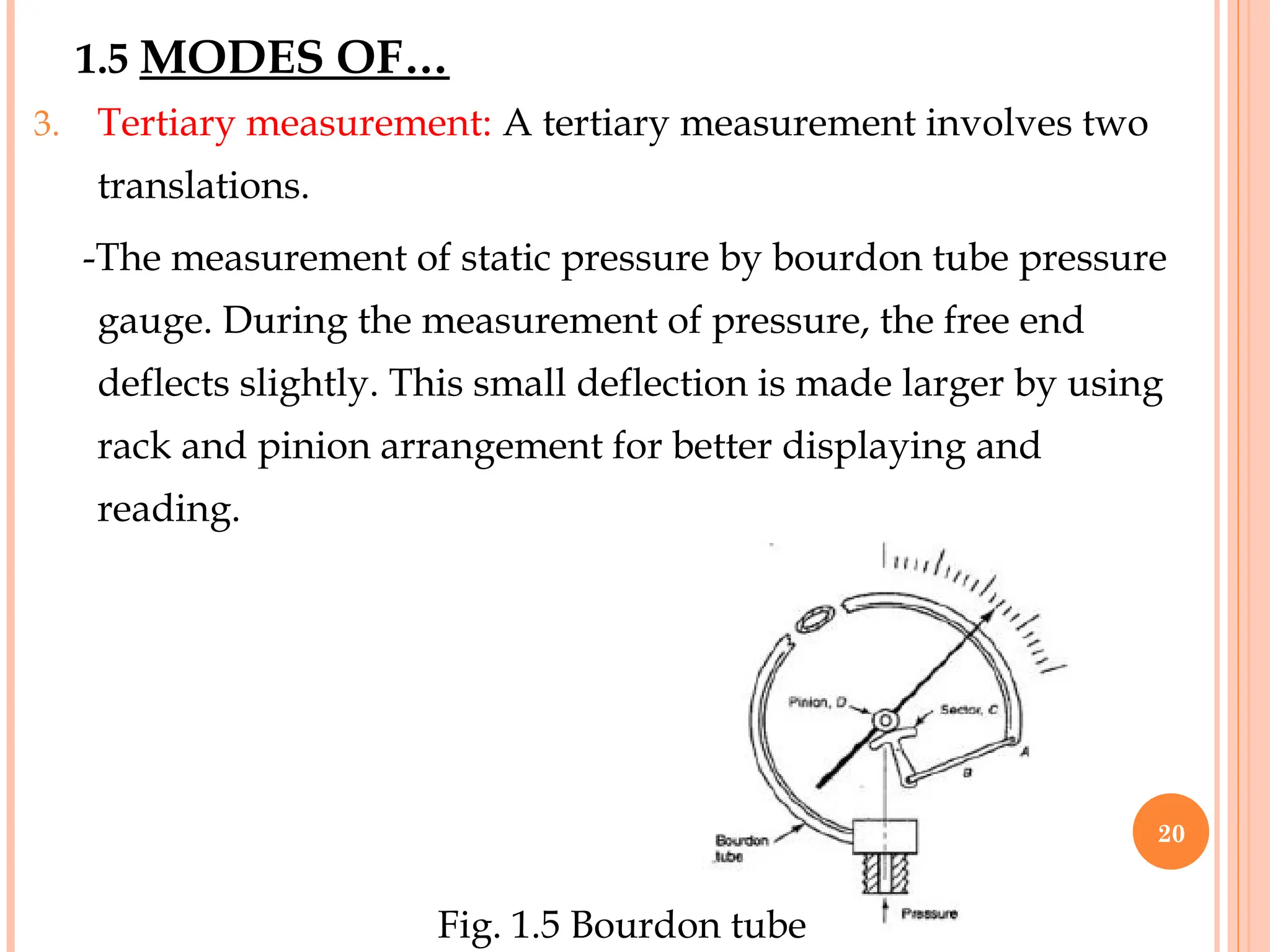

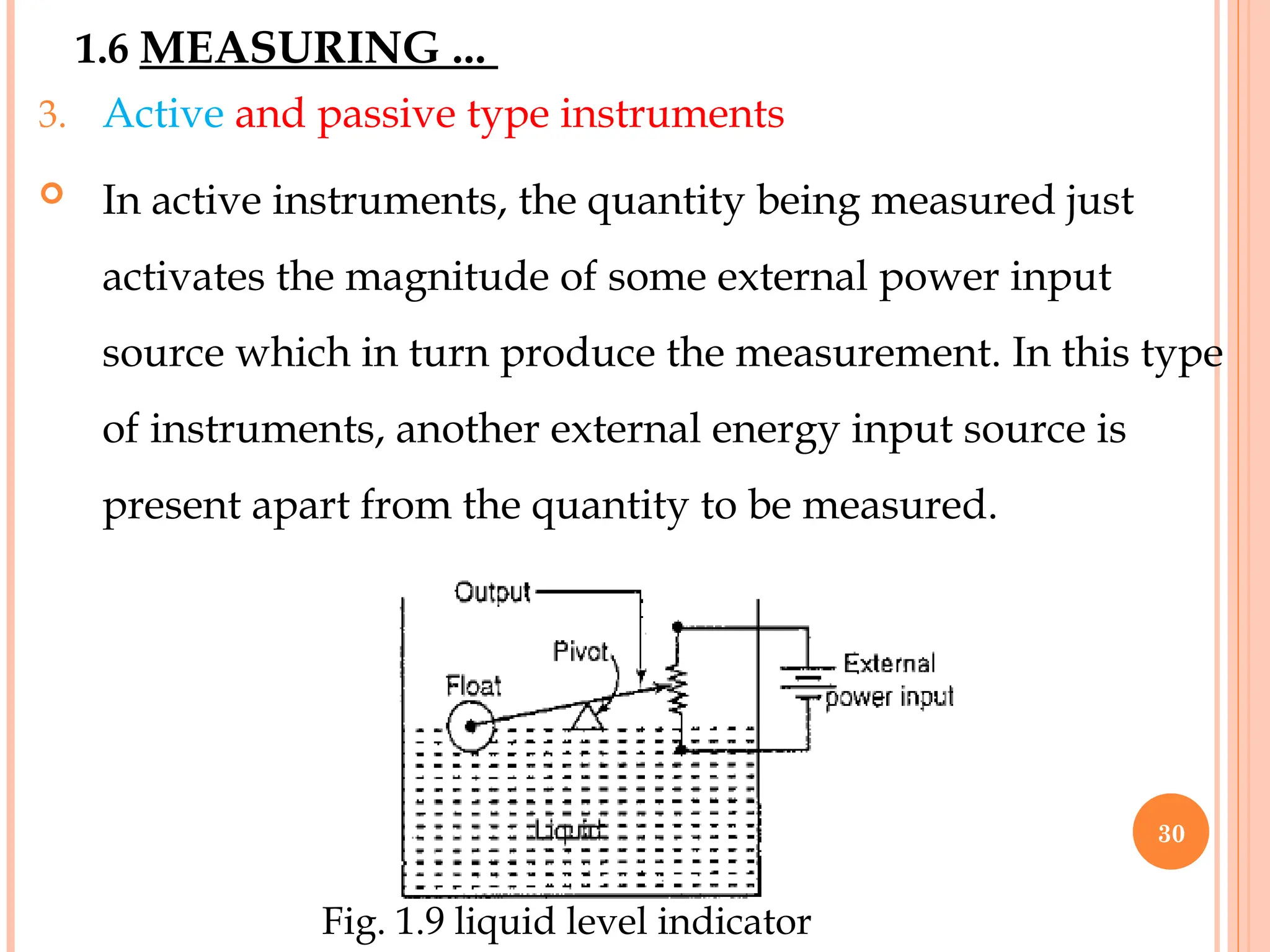

The document provides an overview of measurement concepts, including definitions, methods, and the significance of accurate measurements in various fields. It discusses standardization of measurement, types of measuring instruments, and the classification of measurement methods. The document also emphasizes the importance of calibration and the use of SI units for consistency in measurements.