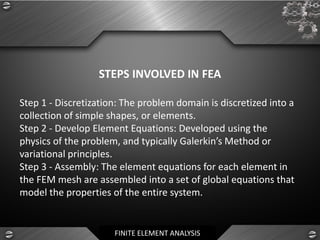

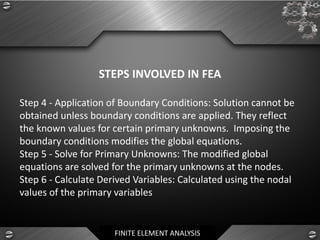

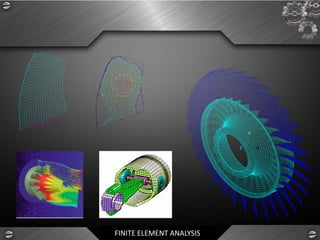

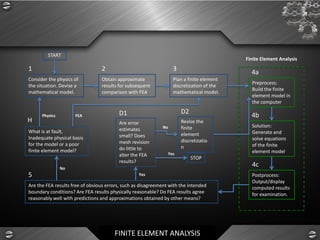

The document provides an overview of finite element analysis (FEA) methods used to solve engineering problems, highlighting traditional design processes and different numerical methods like finite element, boundary element, finite volume, and finite difference methods. It details the FEA procedure, including problem discretization, application of boundary conditions, and solution obtainment, while also discussing the advantages of FEA such as improved visualization, reduced design cycle time, and decreased need for prototypes. Additionally, it introduces SolidWorks simulation software for design analysis, covering various analysis types including linear, nonlinear, dynamic, thermal, and fatigue analysis.