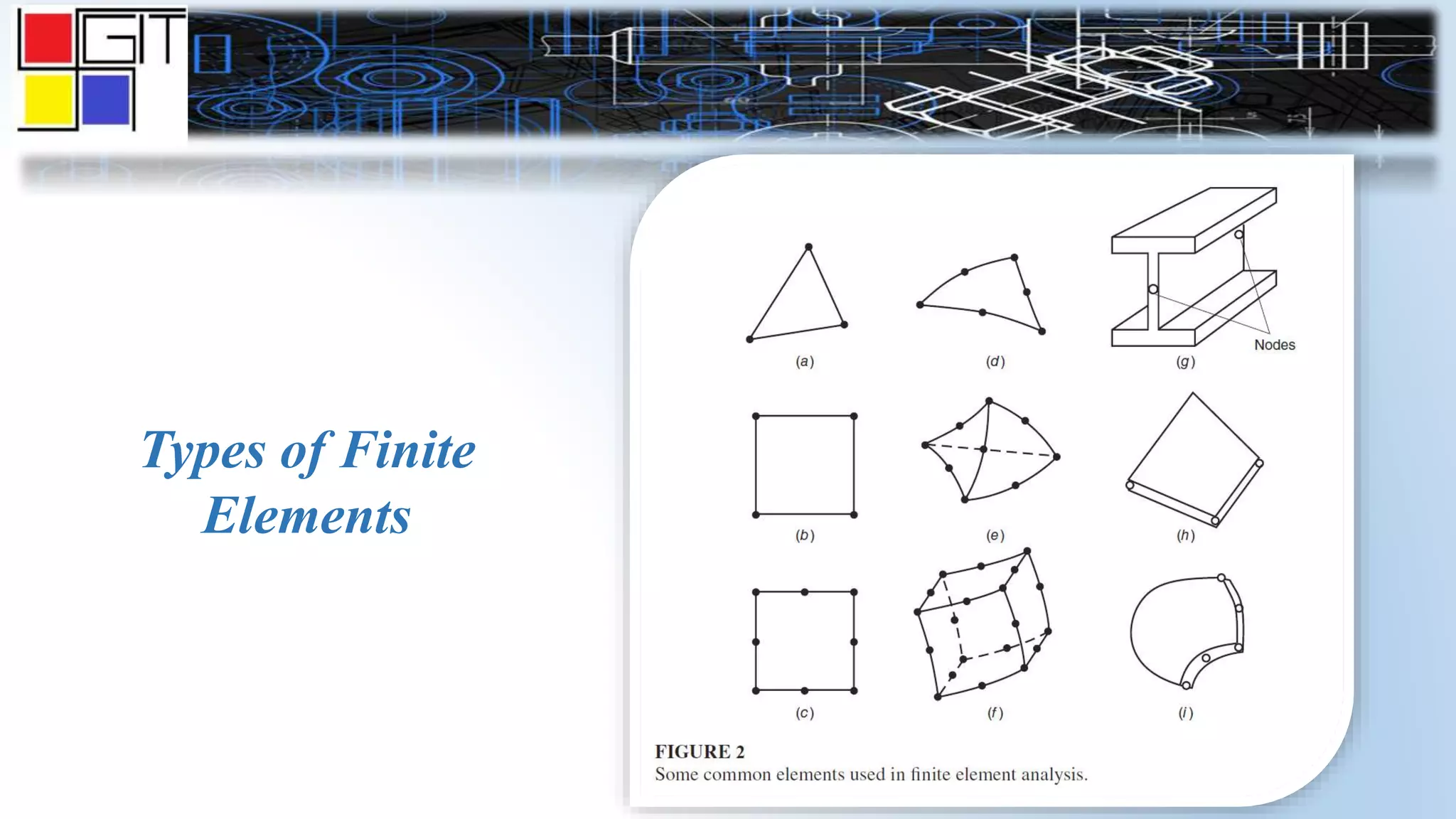

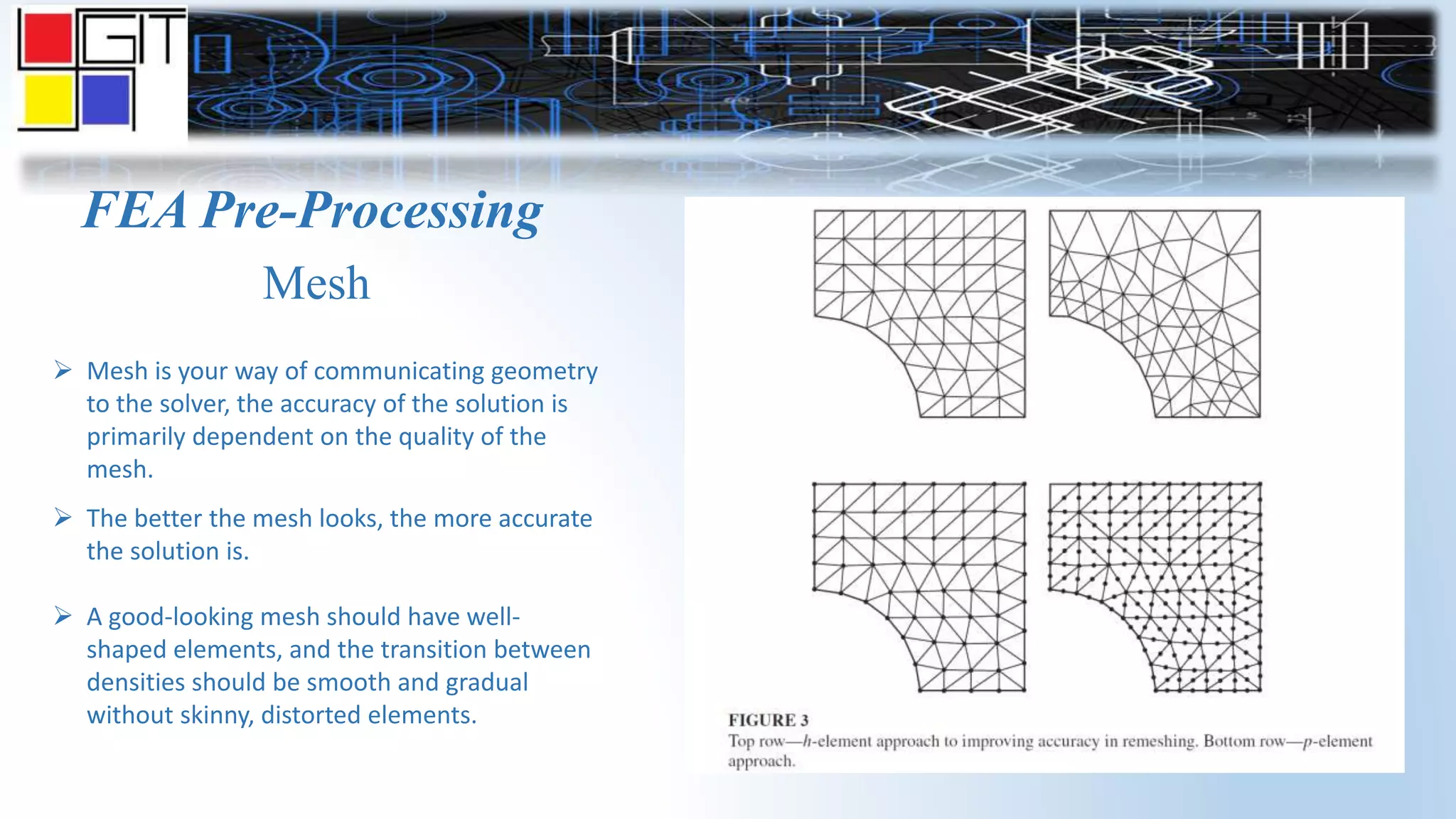

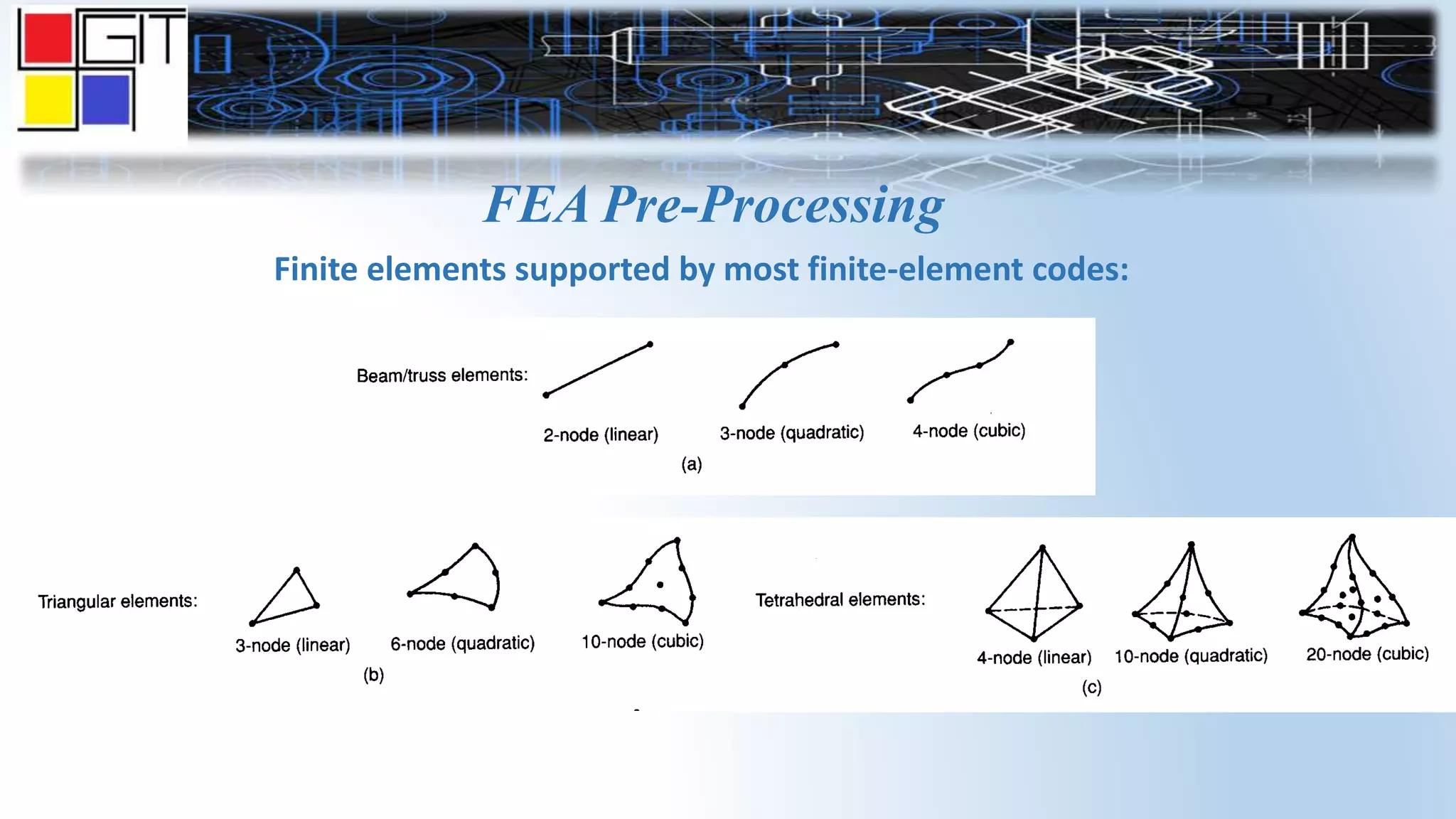

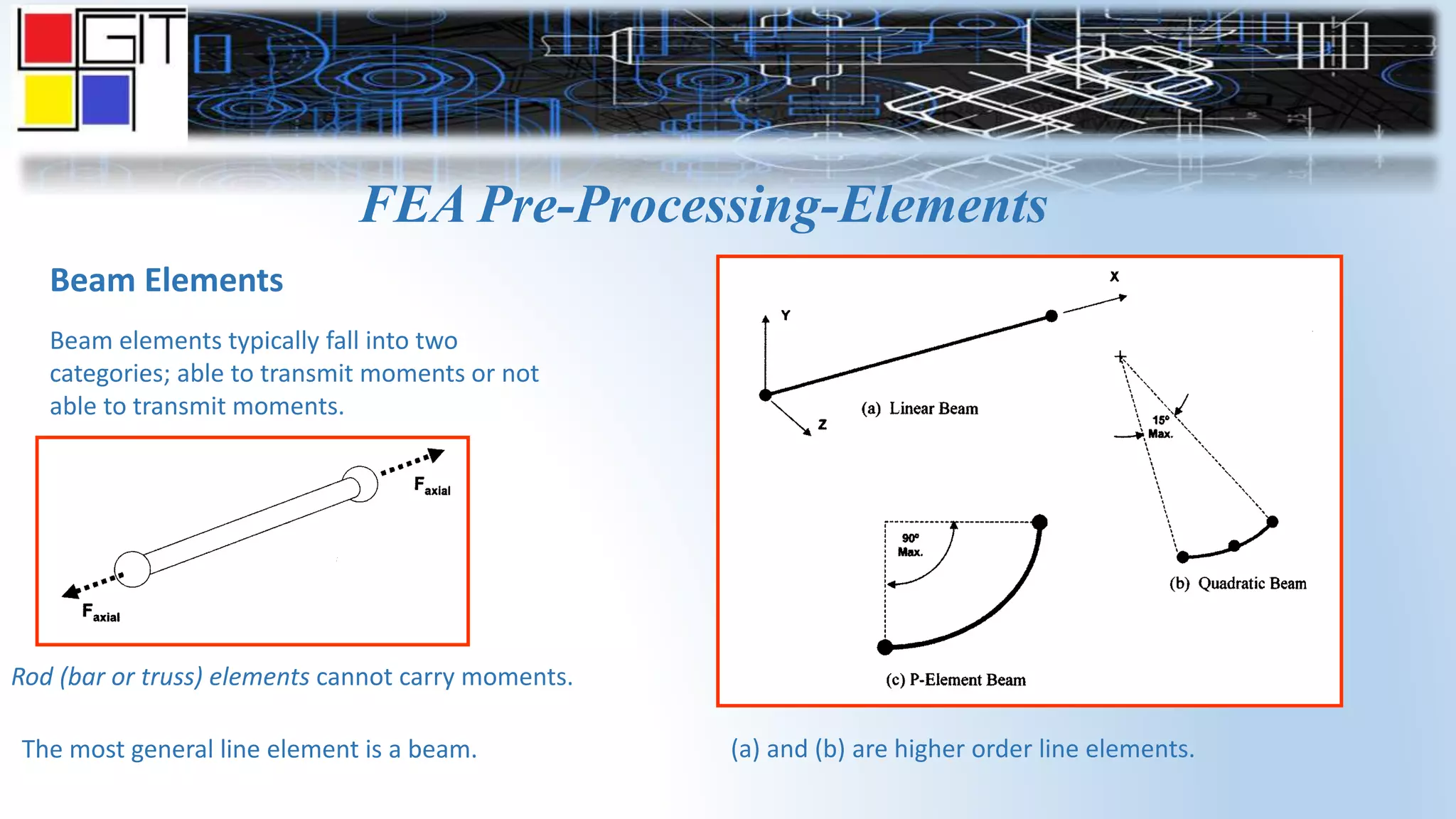

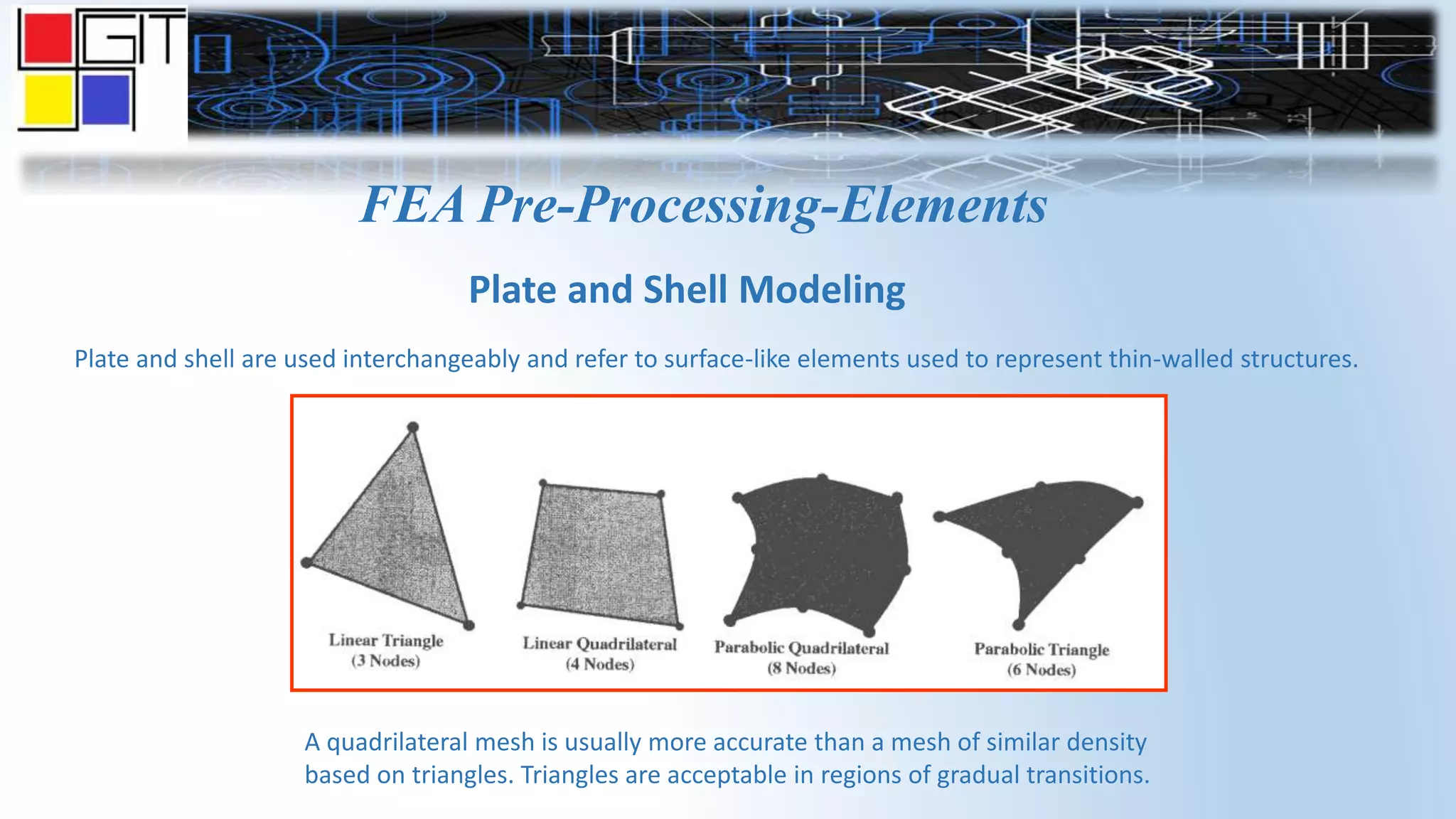

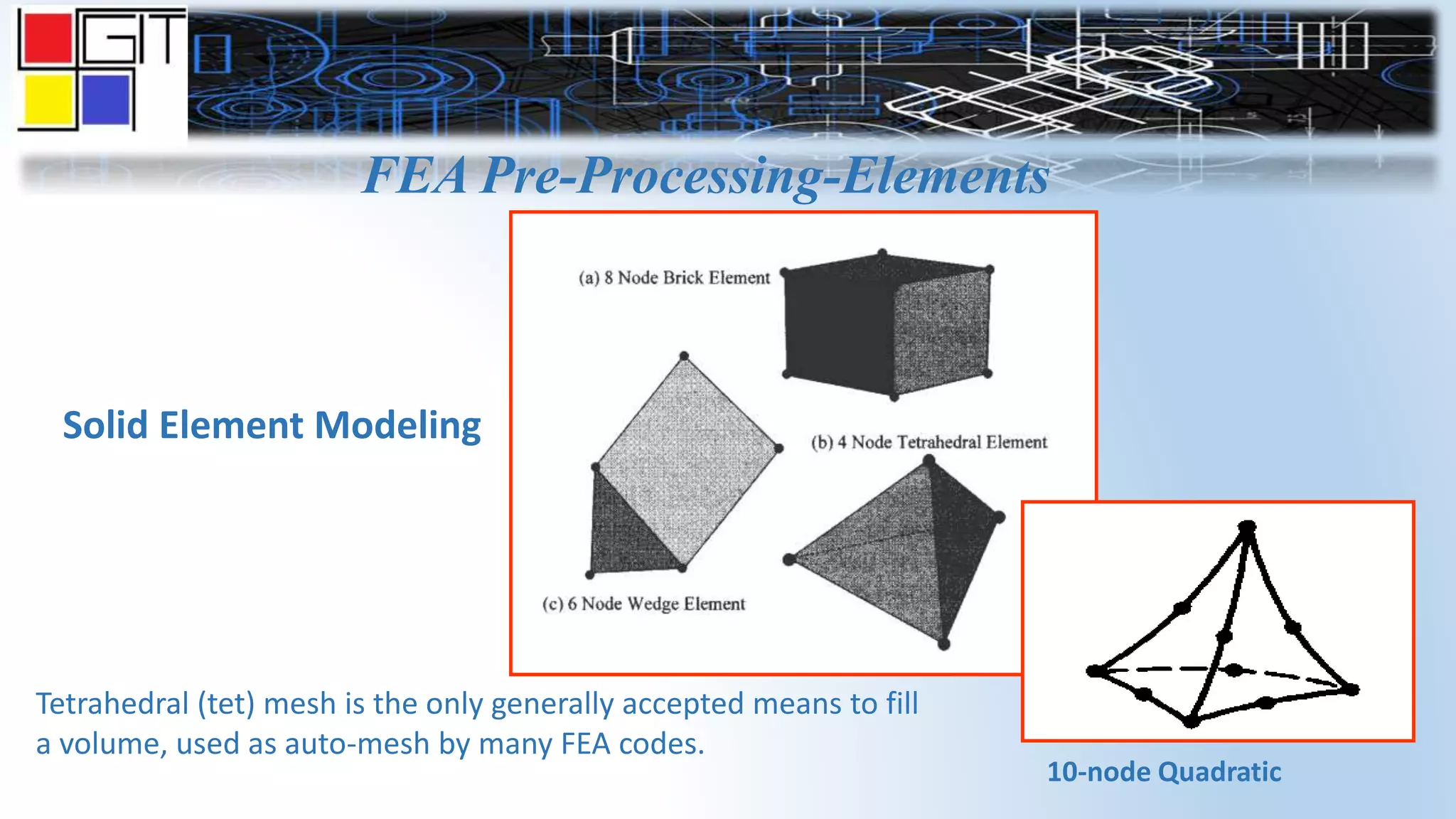

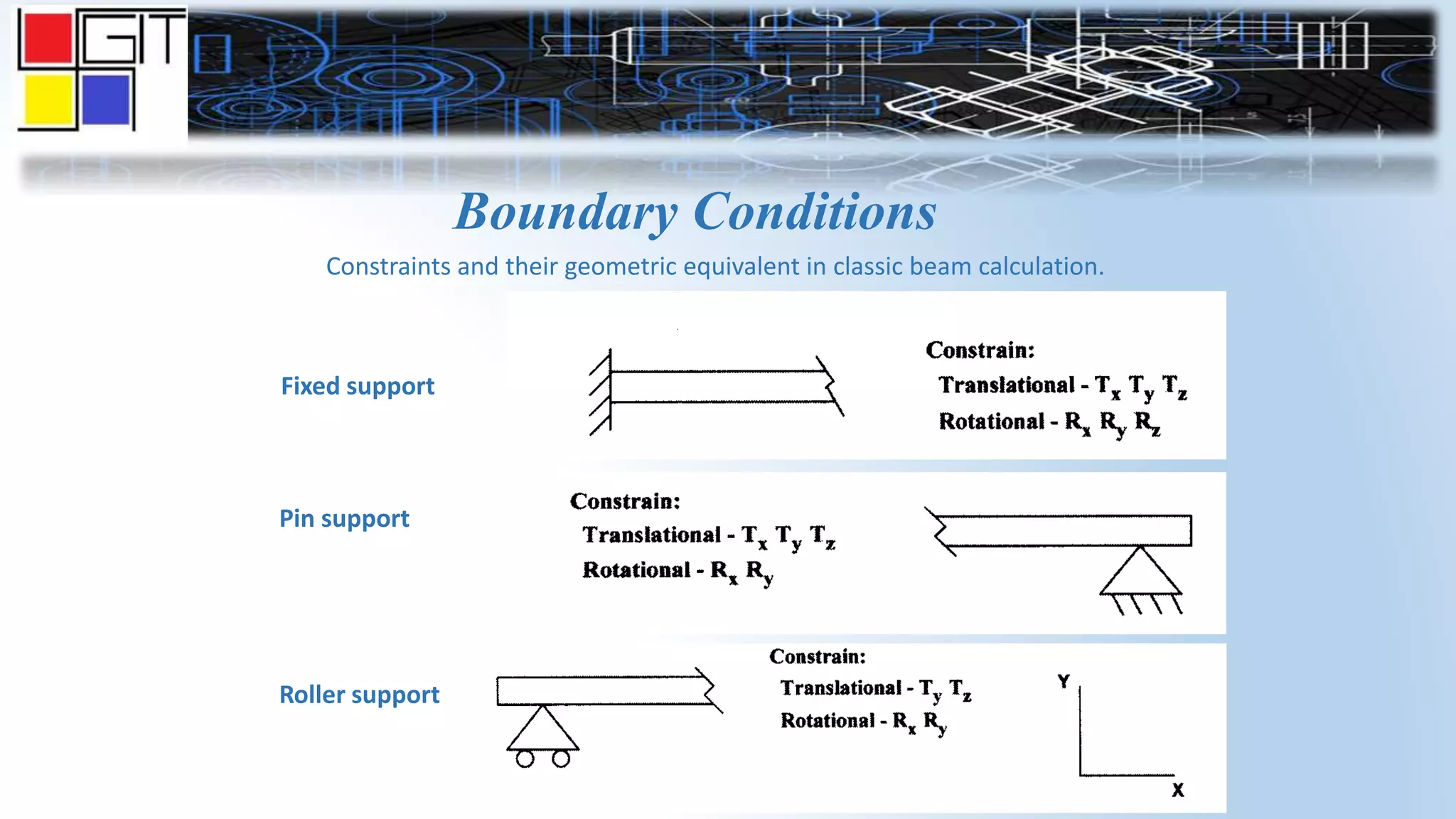

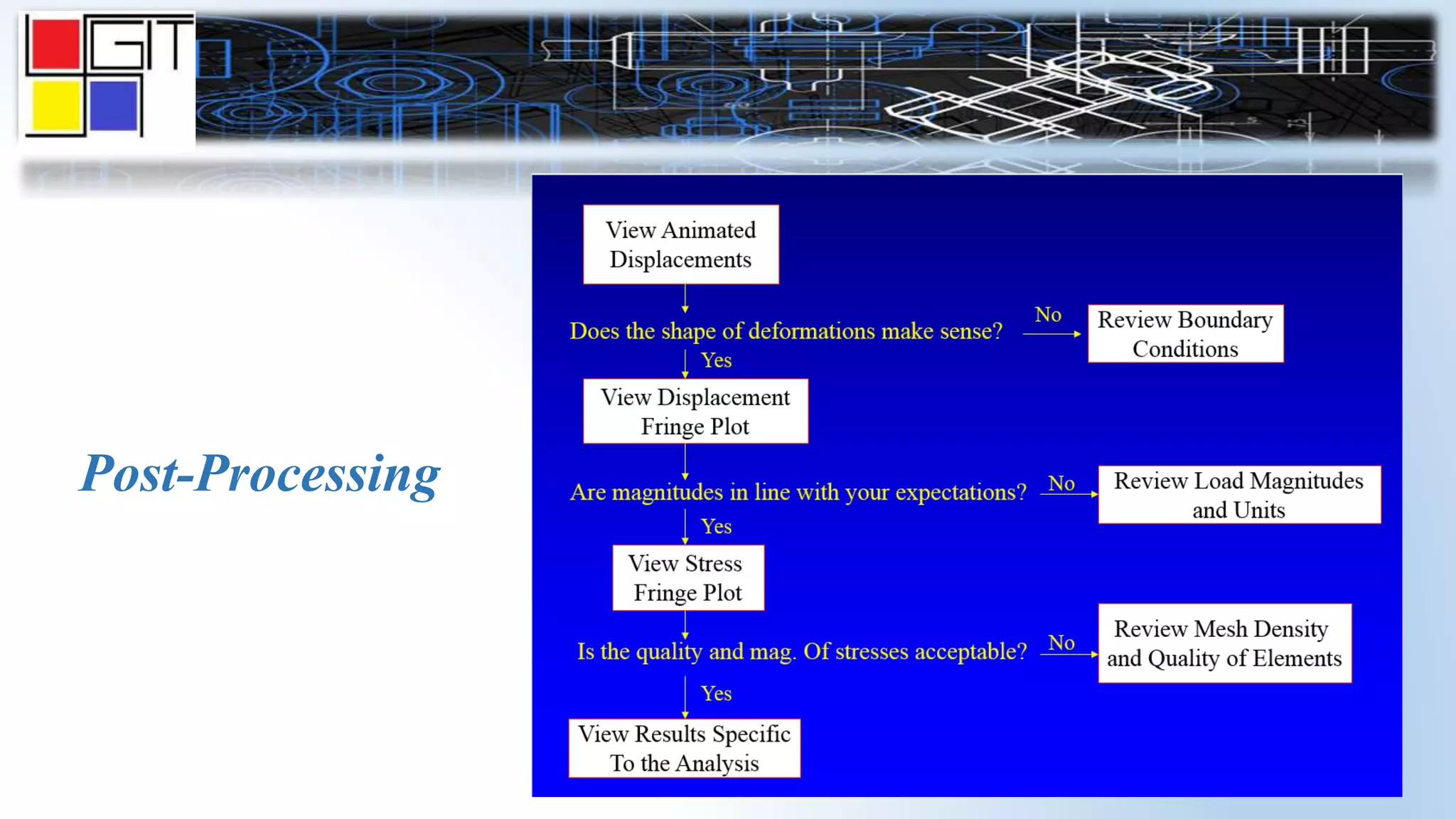

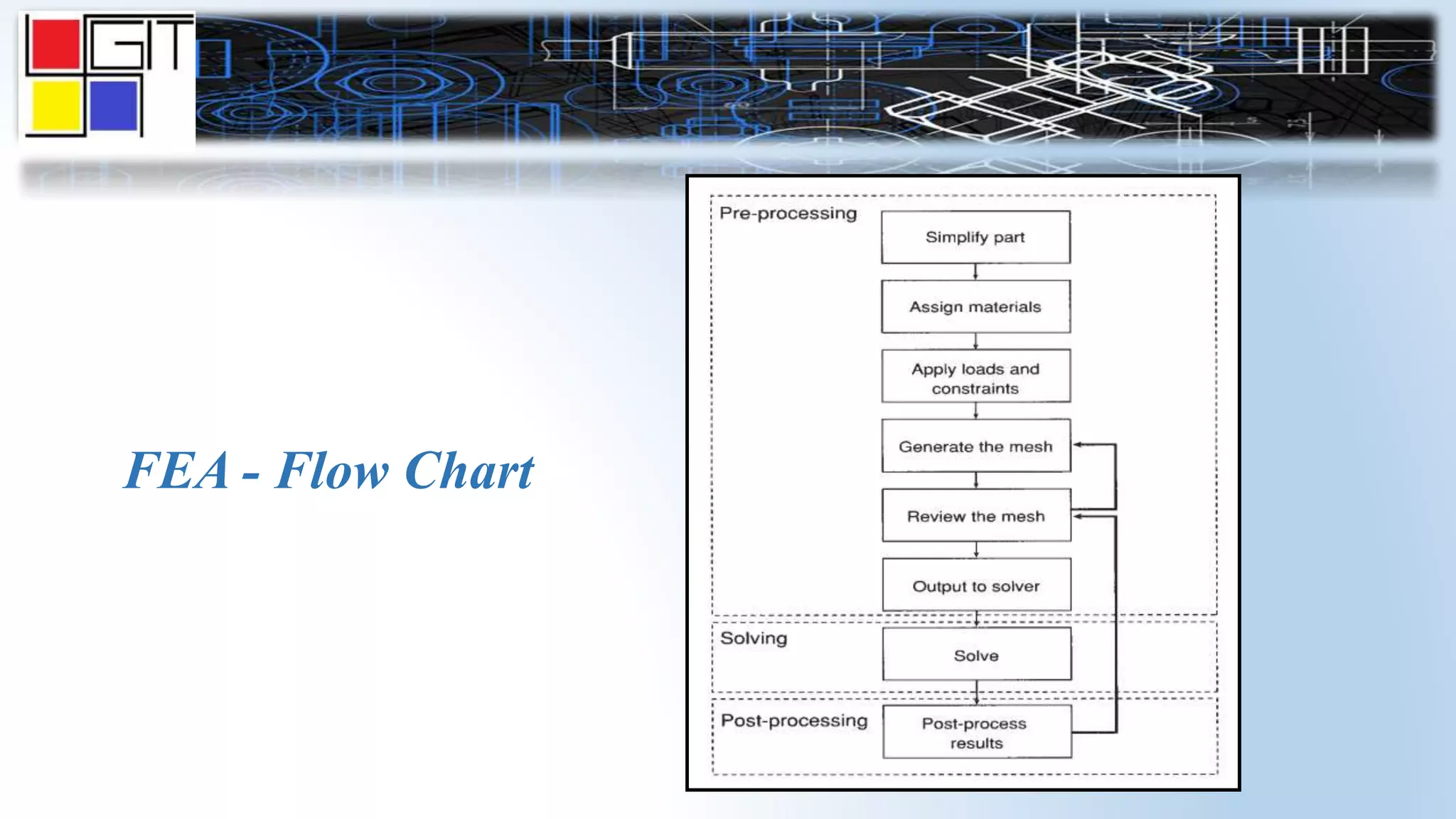

The document provides an overview of the history and basics of finite element analysis (FEA). It discusses how FEA was first developed in 1943 and expanded in the following decades. The basics section describes common FEA applications, basic steps which include converting differential equations to algebraic equations, element types, boundary conditions including loads and constraints, and pre-processing, solving, and post-processing steps. Key element types are also summarized.