The document provides an overview of the finite element method (FEM), detailing its historical development and applications in solving partial differential equations through numerical methods. It discusses the evolution of FEM from early predictions of natural frequency to the integration of FEM with computer-aided design (CAD) in product design processes. Key concepts, one-dimensional rod elements, and two-dimensional trusses are also explained, highlighting methods of analysis such as Rayleigh-Ritz and Galerkin's method.

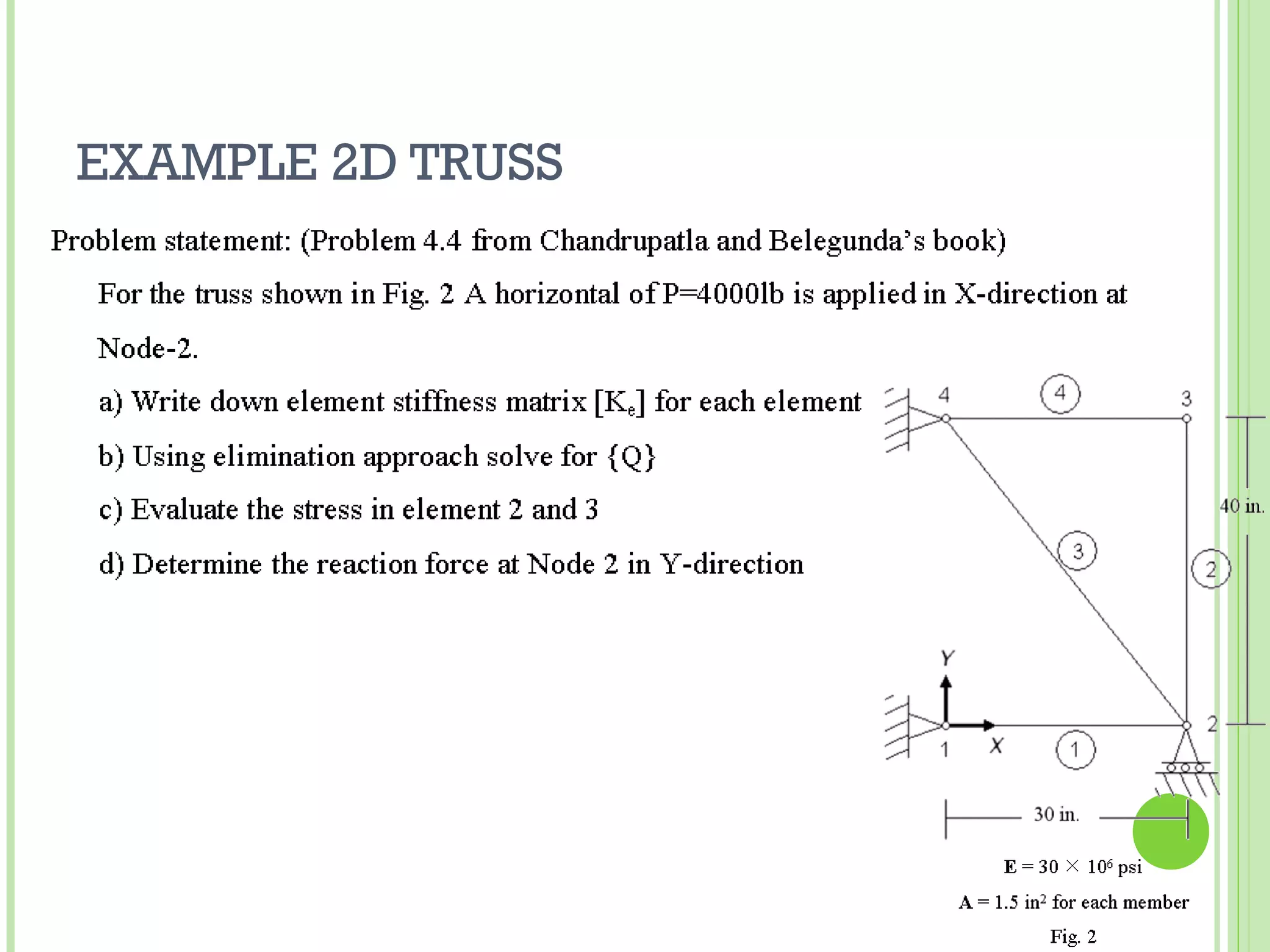

![1D ROD ELEMENTS Element -1 Element-2

1 T e

Element strain energy U e = q [k ]q

2

Element stiffness matrix

E e Ae 1 − 1

[k ] =

e

− 1 1

le

Load vectors

Element body load vector

Element traction-force vector e Ae l e f 1

f =

2 1

e Tl e 1

T =

2 1](https://image.slidesharecdn.com/femppt-130313204553-phpapp01/75/Introduction-to-finite-element-method-fem-12-2048.jpg)

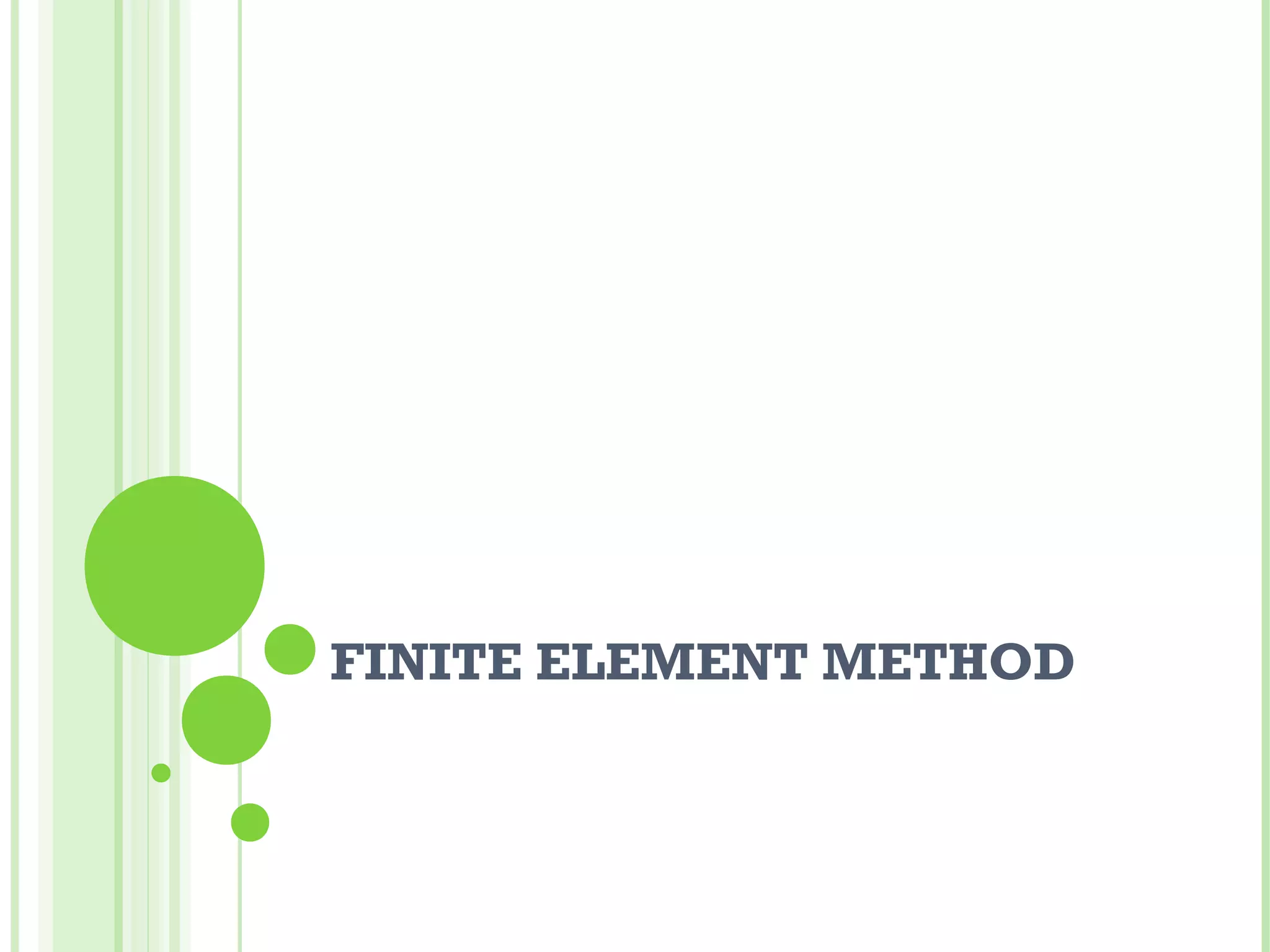

![2D TRUSS

Transformation Matrix

Direction Cosines

le = ( x2 − x1 ) 2 + ( y 2 − y1 ) 2

x 2 − x1

l m 0 0 l = cos θ =

[ L] = le

0 0 l m

y 2 − y1

m = sin θ =

le](https://image.slidesharecdn.com/femppt-130313204553-phpapp01/75/Introduction-to-finite-element-method-fem-14-2048.jpg)

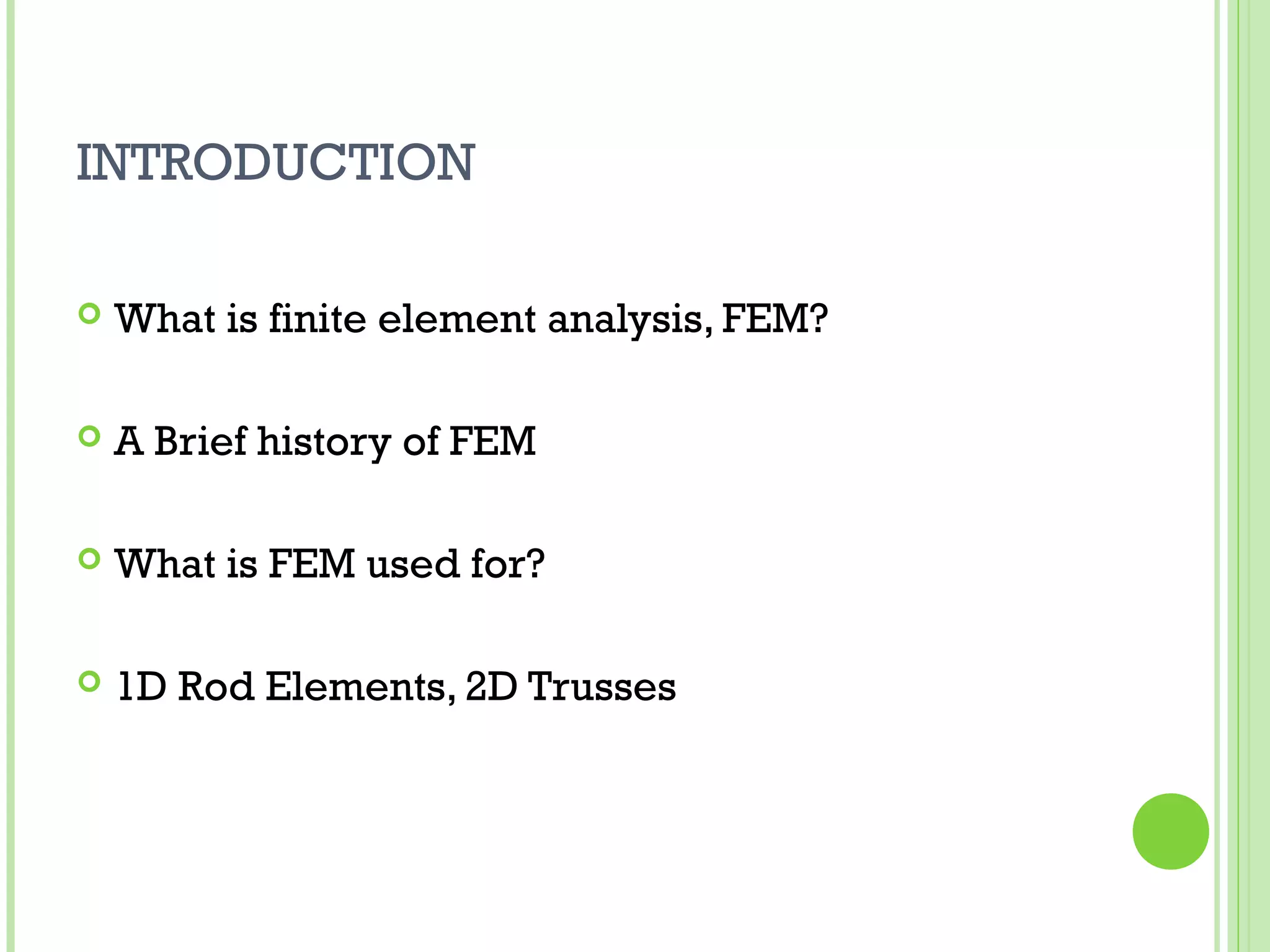

![2D TRUSS

Element Stiffness Matrix

l2 lm − l 2 − lm

2

E e Ae lm m2 − lm − m

[k e ] =

l e − l 2 − lm l2 lm

2

− lm − m

2

lm m ](https://image.slidesharecdn.com/femppt-130313204553-phpapp01/75/Introduction-to-finite-element-method-fem-15-2048.jpg)

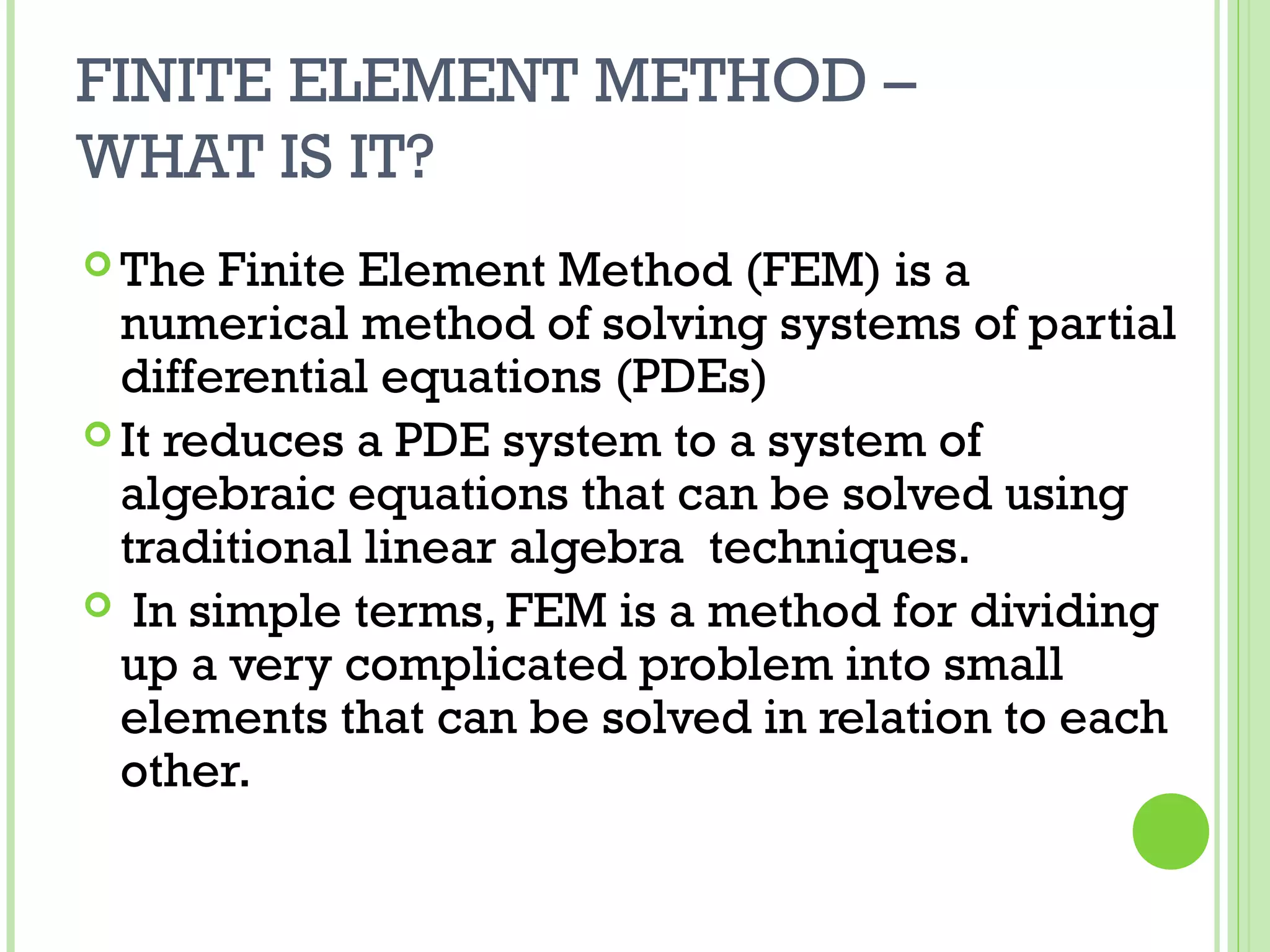

![2D TRUSS

Element Stresses

Ee

σ= [ − l − m l m] q

le

Element Reaction Forces

R = [ K ]Q](https://image.slidesharecdn.com/femppt-130313204553-phpapp01/75/Introduction-to-finite-element-method-fem-19-2048.jpg)

![3D TRUSS STIFFNESS MATRIX

3D Transformation Matrix

Direction Cosines

l m n 0 0 0

[ L] =

0 0 0 l m n

le = ( x 2 − x1 ) 2 + ( y 2 − y1 ) 2 + ( z 2 − z1 ) 2

x 2 − x1 y 2 − y1 z 2 − z1

l = cos θ = m = cos φ = n = cos ϕ =

le le le](https://image.slidesharecdn.com/femppt-130313204553-phpapp01/75/Introduction-to-finite-element-method-fem-24-2048.jpg)

![3D TRUSS STIFFNESS MATRIX

3D Stiffness Matrix

l2 lm ln − l 2 − lm − ln

lm m2 mn − lm − m 2 − mn

E e Ae ln mn n2 − ln − mn − n 2

[k e ] =

l e − l 2 − lm − ln l 2

lm ln

− lm − m 2 − mn lm m2 mn

− ln − mn − n

2 2

ln mn n ](https://image.slidesharecdn.com/femppt-130313204553-phpapp01/75/Introduction-to-finite-element-method-fem-25-2048.jpg)