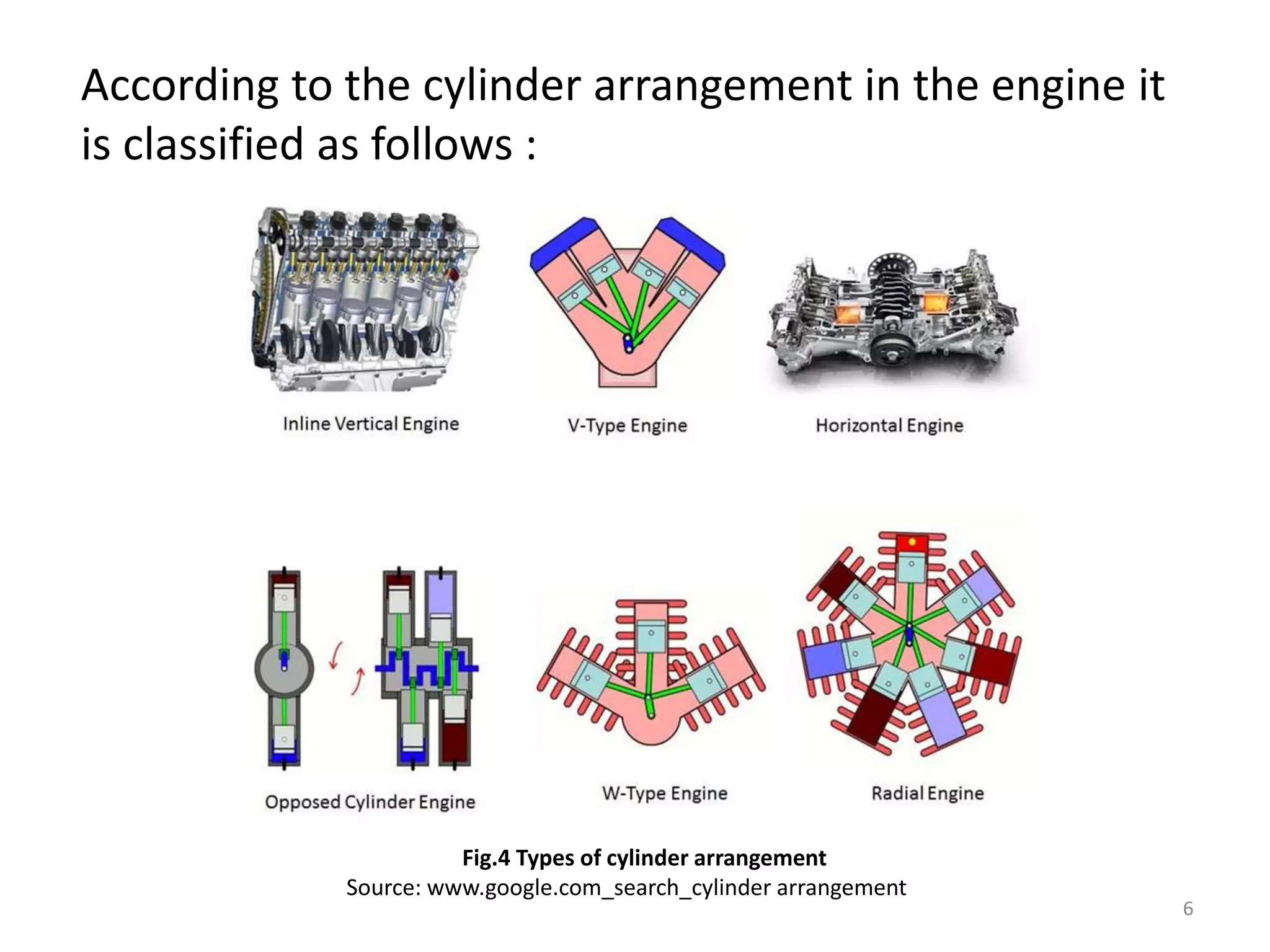

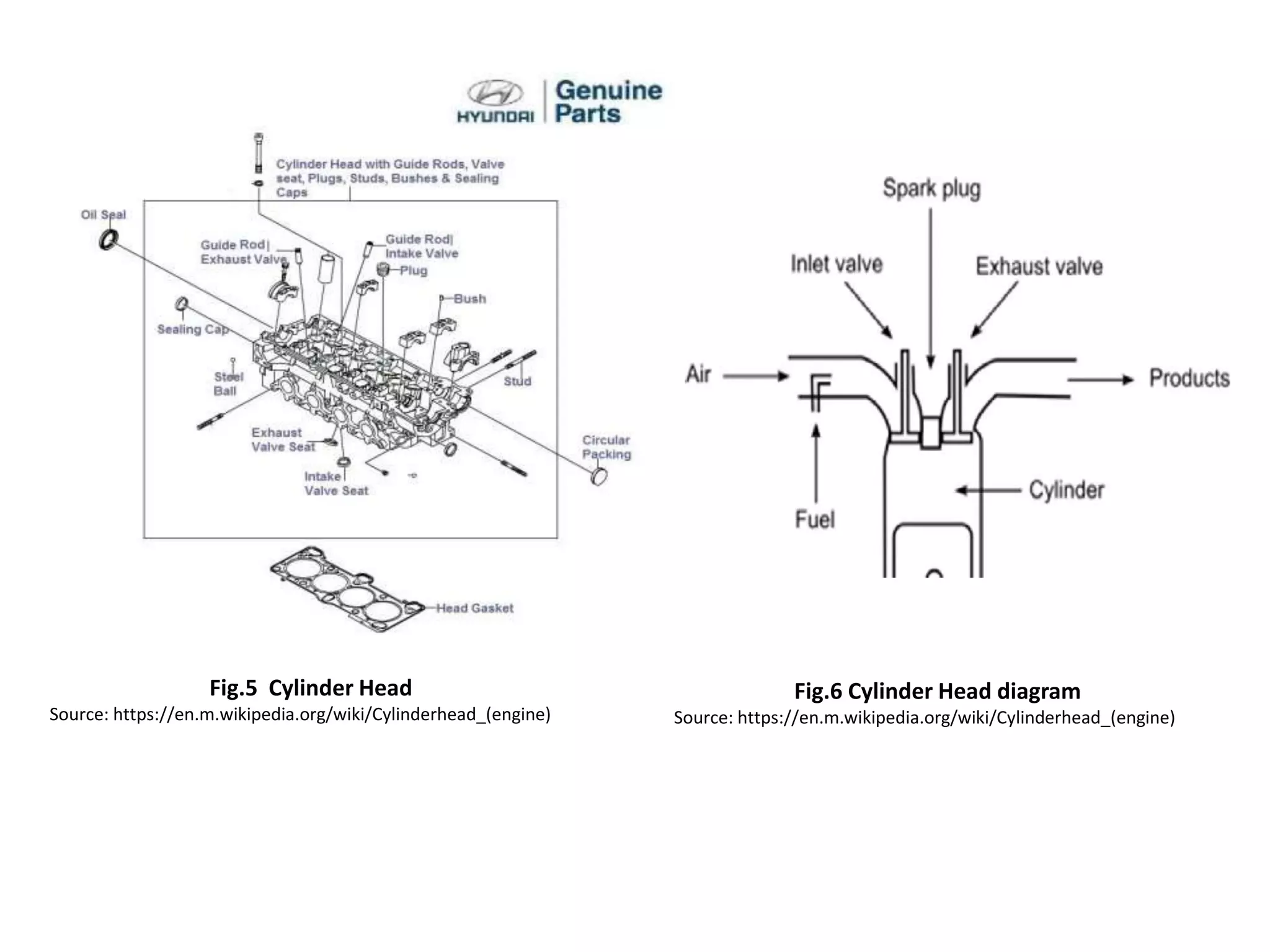

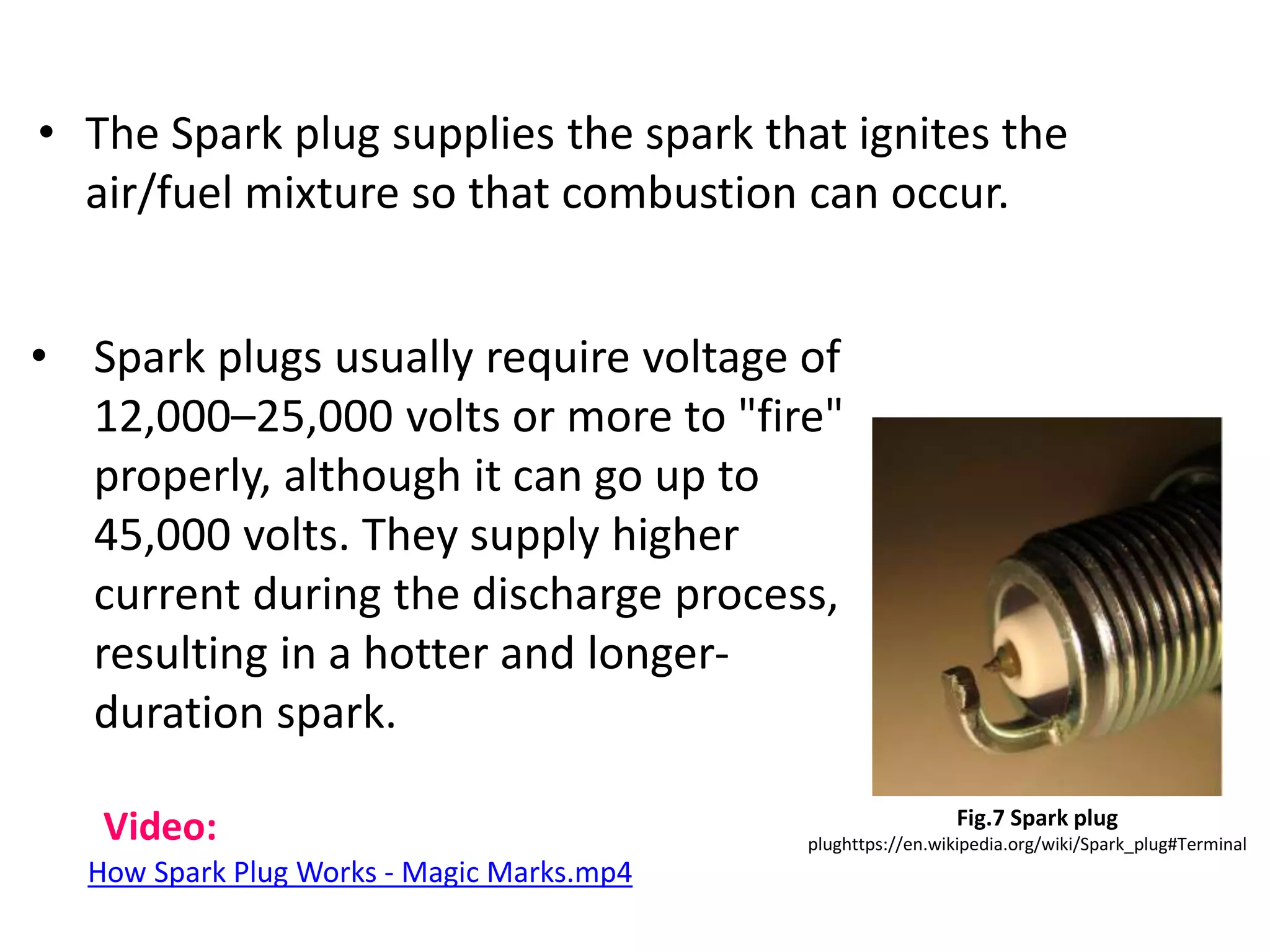

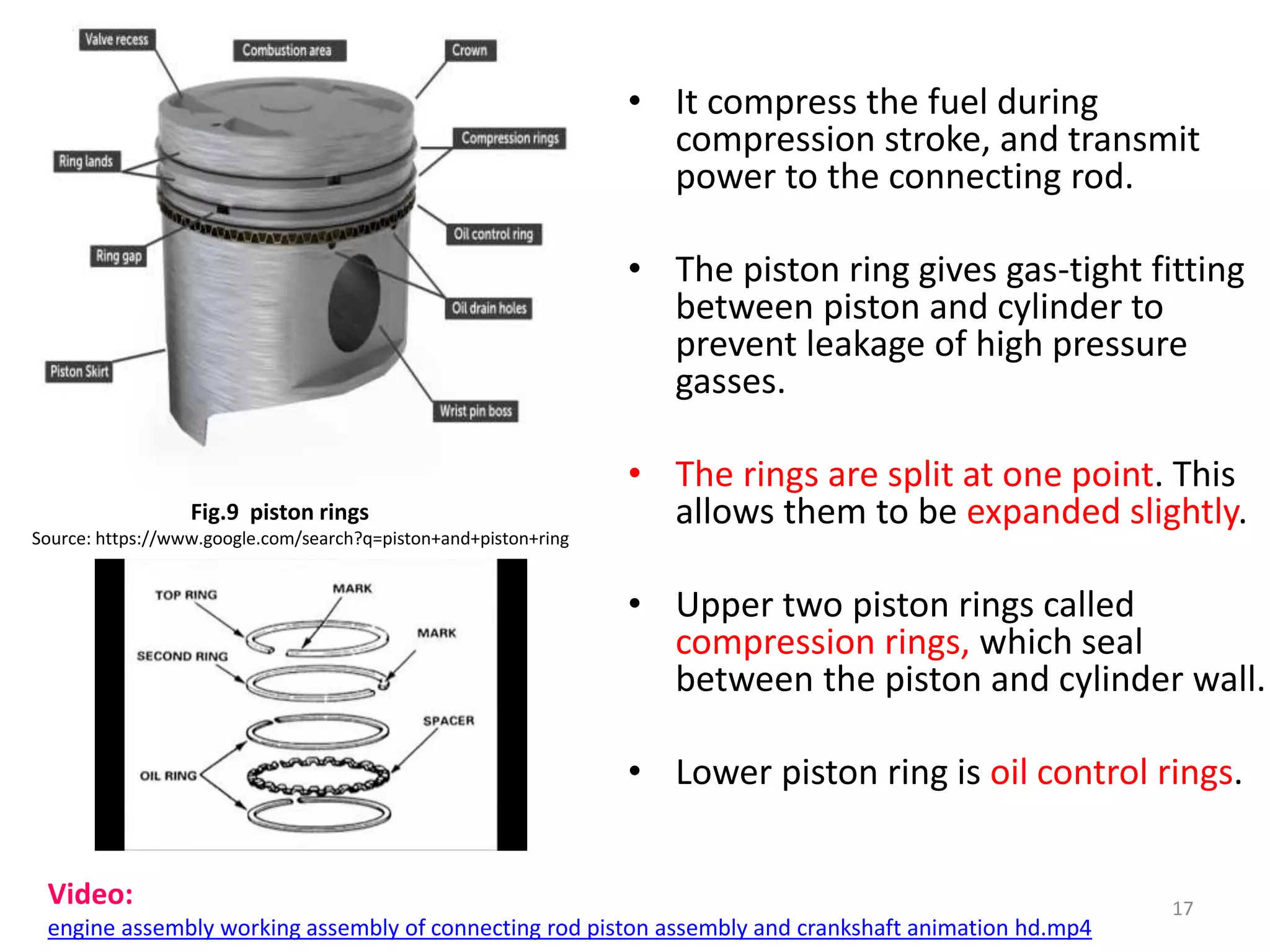

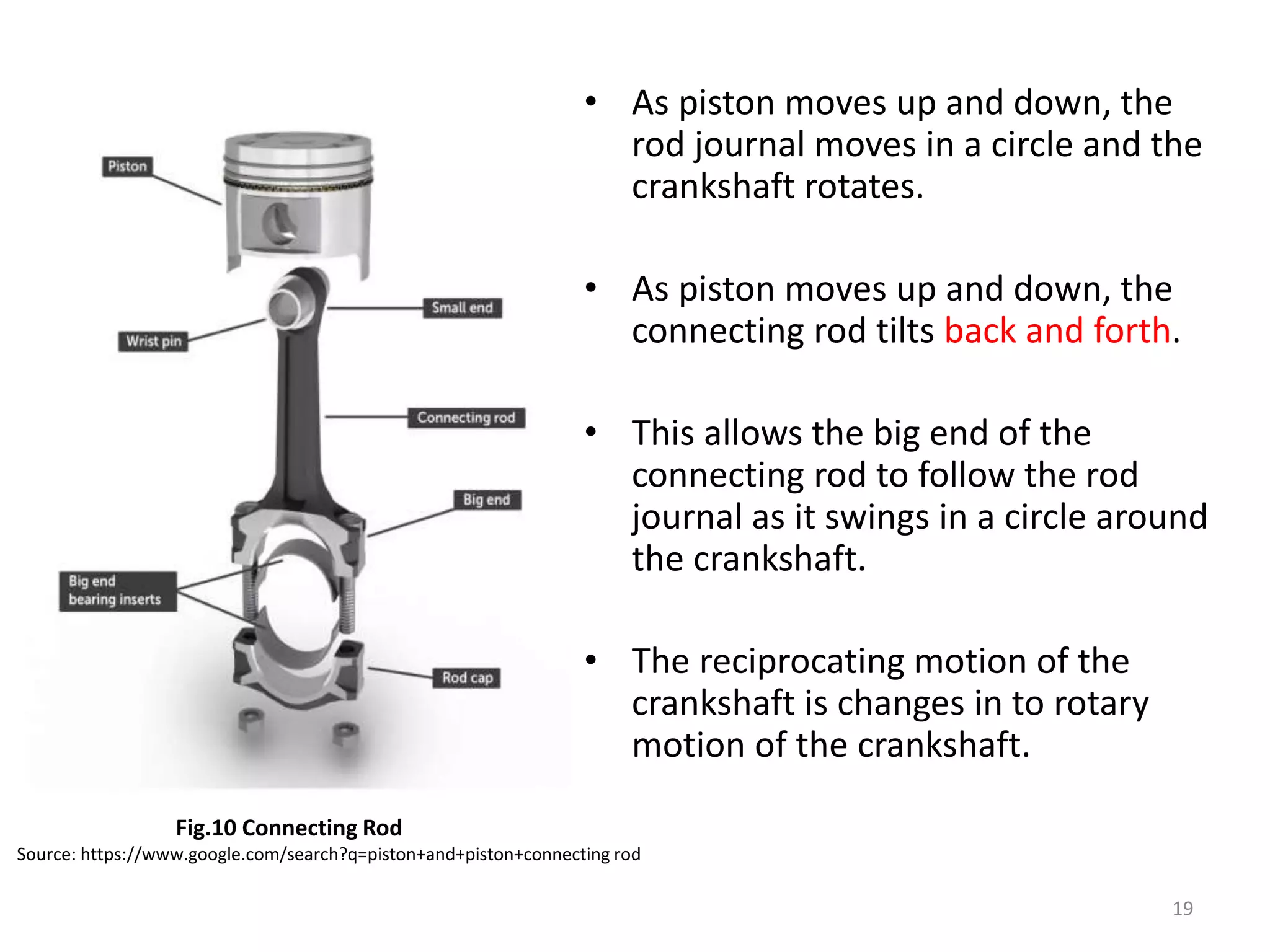

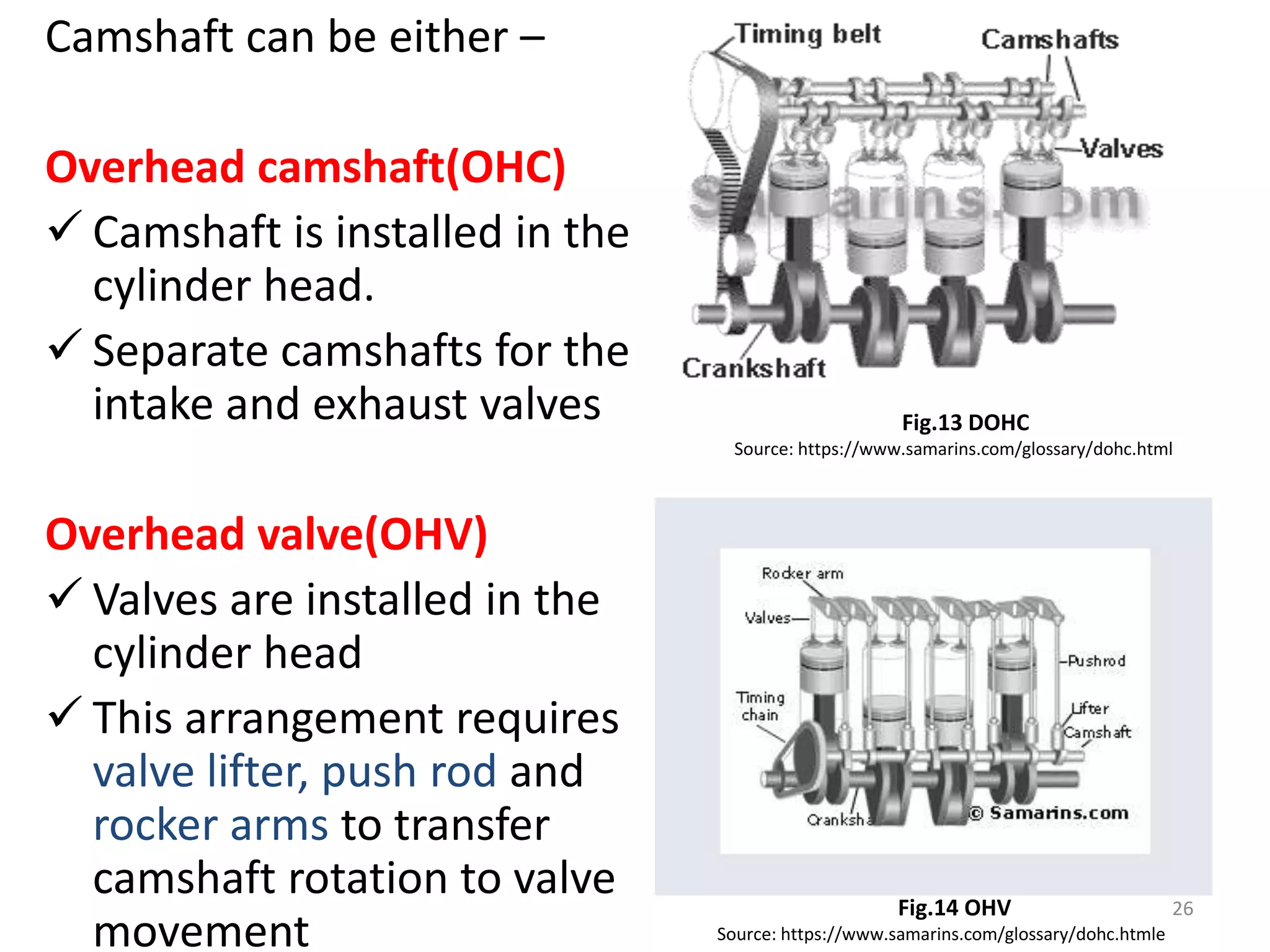

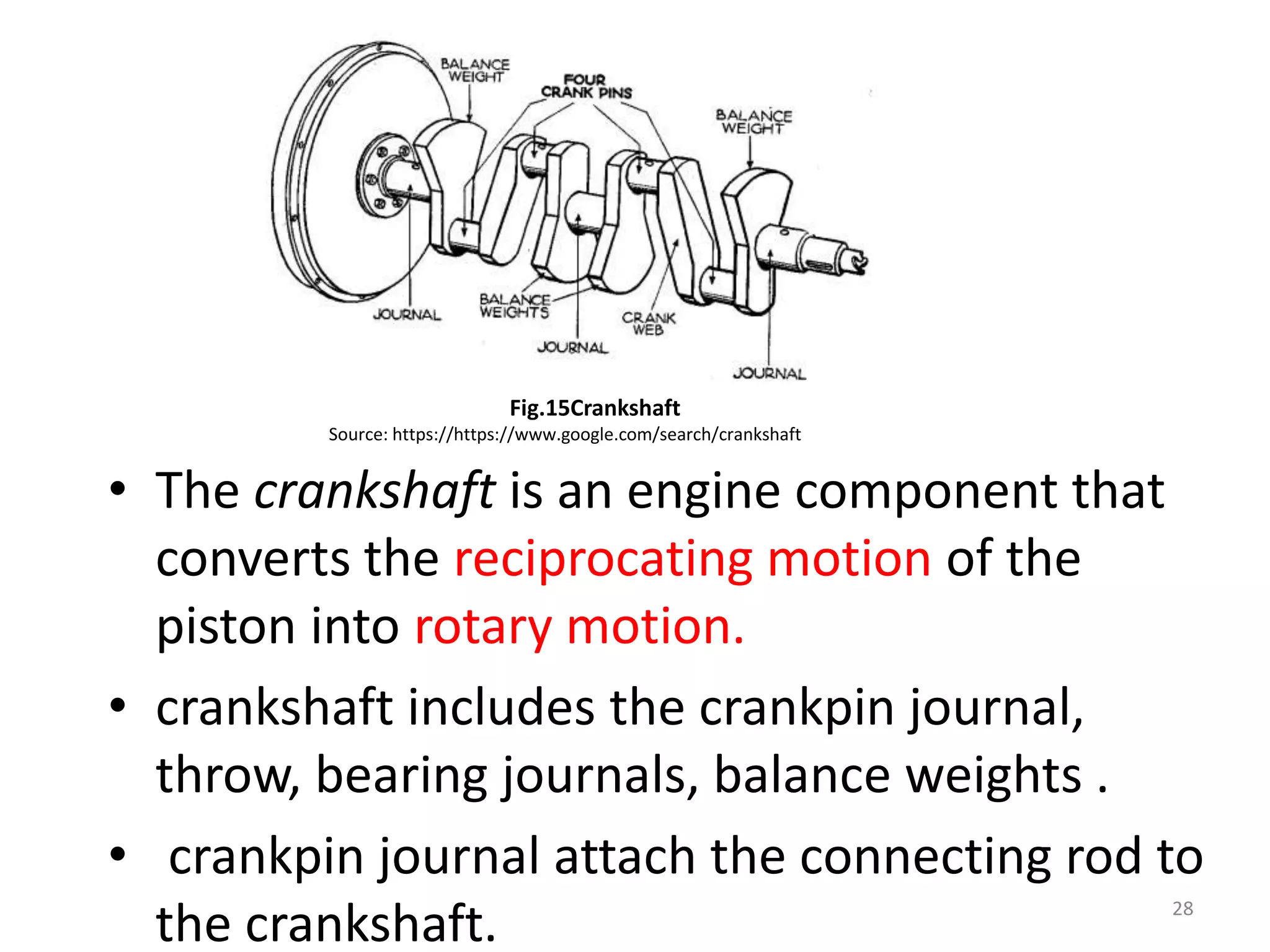

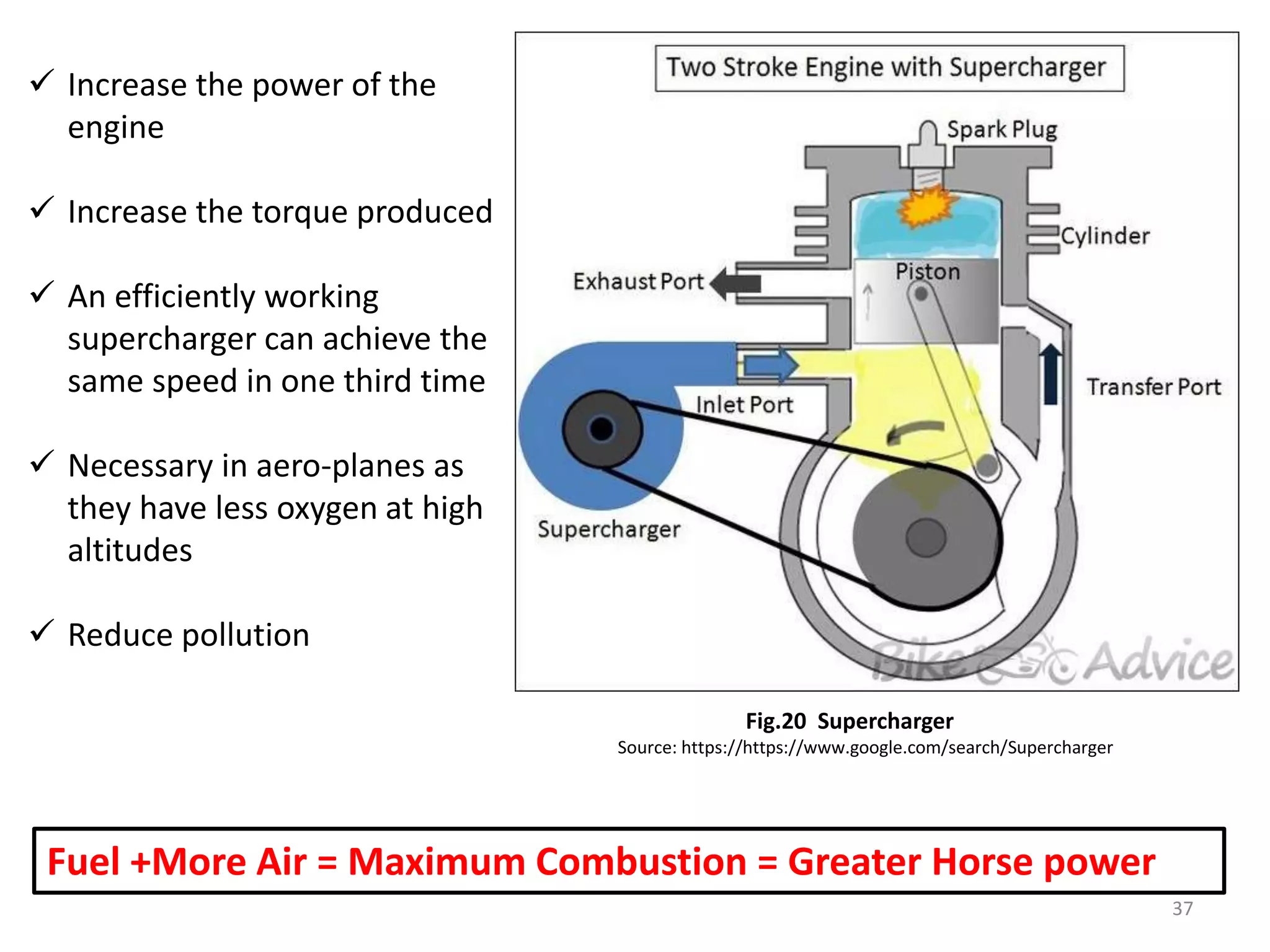

The document provides an in-depth overview of the various components of an internal combustion engine, including the cylinder block, cylinder head, spark plugs, pistons, connecting rods, fuel injectors, valves, camshaft, crankshaft, flywheel, timing chain, turbocharger, and supercharger. Each component's function, materials, and operational importance are discussed, highlighting their roles in the engine's performance and efficiency. The document also includes diagrams and illustrations to aid in understanding the complex relationships between these parts.