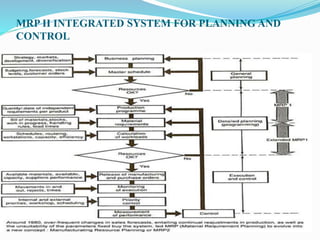

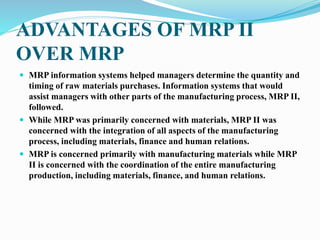

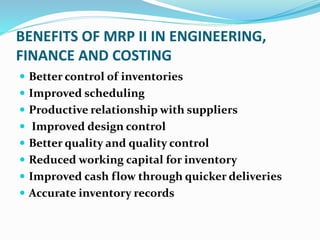

MRP II is an integrated information system that synchronizes all aspects of a business, including sales, purchasing, manufacturing, finance, and engineering. It coordinates these areas by adopting a focal production plan and using a unified database to plan and update activities across all systems. MRP II provides feedback on resource adequacy and commitments as well as performance quality to help improve planning and control in manufacturing.