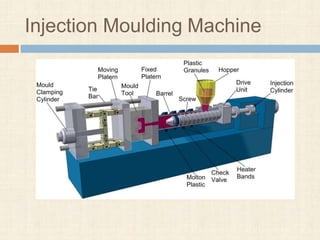

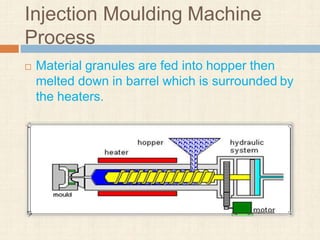

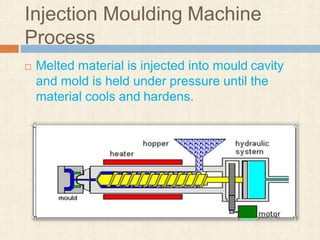

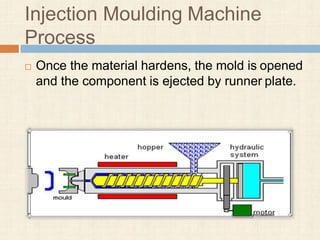

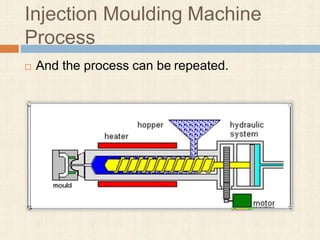

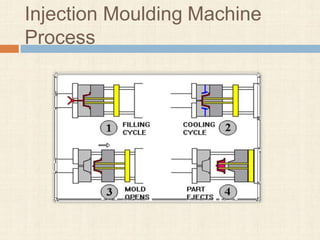

Injection moulding is a manufacturing process that involves injecting material into a mould cavity. Common materials used include thermoplastics and thermosets. The injection moulding machine has components like a clamping unit, injection unit, mould, and heaters. It injects molten material into the mould, which then cools and hardens into the final shape before being ejected. Injection moulding is used to make a wide variety of plastic, rubber and metal parts.