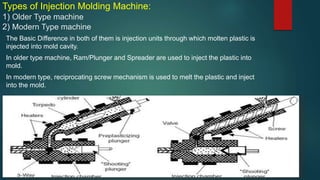

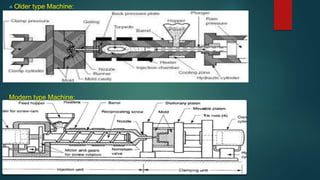

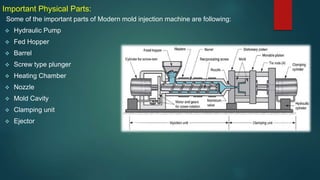

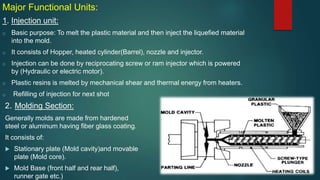

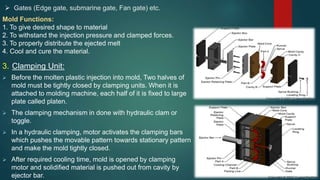

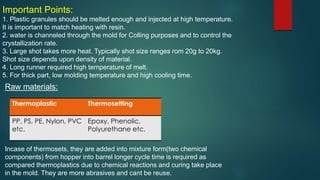

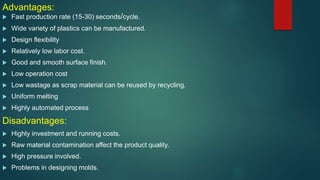

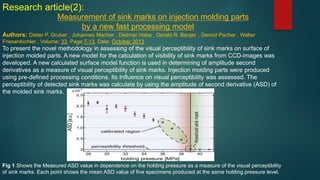

The document discusses injection molding techniques. It begins by defining injection molding as a process where molten plastic is injected into a mold to produce parts. It describes the basic components of older and modern injection molding machines. The process involves plastic pellets being melted and injected under pressure into molds through a nozzle to produce parts, which then cool and are ejected. Key advantages are high production rates and the ability to produce complex parts in various plastics.