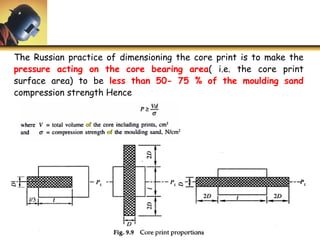

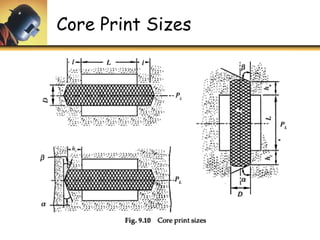

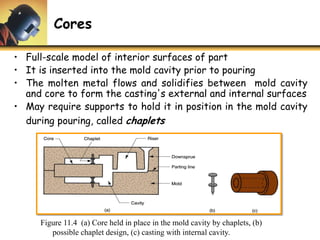

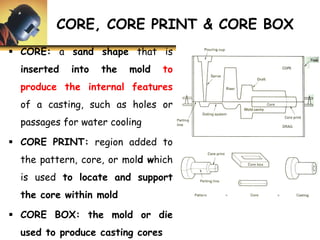

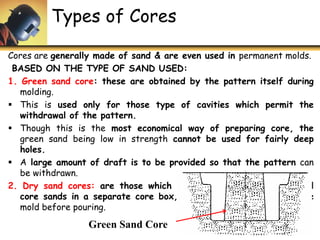

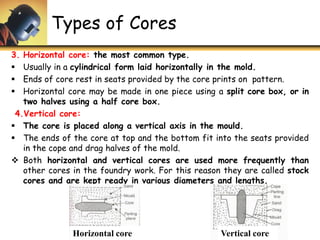

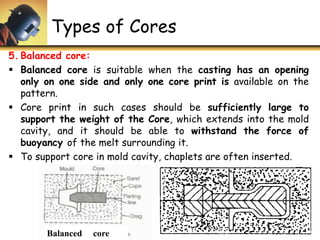

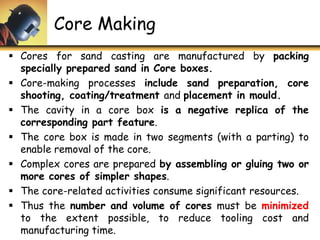

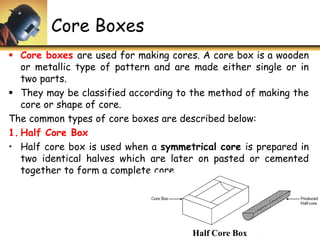

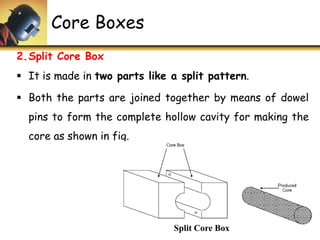

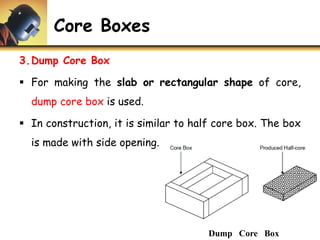

This document discusses sheet metal operations and core manufacturing in casting. It defines cores as models of interior surfaces that are inserted into molds. Cores require supports like chaplets to hold them in position. The document outlines core parts, types, characteristics, functions and manufacturing. Cores are made of sand or metal and can be horizontal, vertical, balanced or hanging depending on their shape and position in molds. Core boxes are used to form cores and come in types like half, split, dump and loose piece. Core prints secure cores and must withstand forces from the molten metal. The document provides equations and guidelines for proper core print sizing.

![Design Of Core Prints

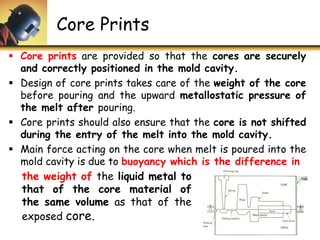

Core prints should be able to take care of weight of core before pouring &

upward metallostatic pressure of molten metal after pouring.

The core print should ensure that core is not shifted during the entry of

metal into mould cavity

The main force acting on the core when metal is poured into mould cavity is

due to buoyancy.

Buoyant force is the difference in the weight of the liquid metal to that of

the core material of the same volume as that of the exposed core.

Mathematically

For horizontal core P = V(ρ-d)

P = Buoyant force, N

V = Volume of the core in the mould cavity, cm3 (Volume = 0.25 π D2 H)

ρ = Weight density of the liquid metal, N/cm3

d = weight density of core material= 1.65x 10-2 N/cm3

For vertical core, Buoyant force P= [0.25 π (D1

2 - D2 ) H ρ– Vd]

Where V= total volume of the core in the mould

A core should be able to support a load of 35 N/cm2 of surface area to keep core in

position . A core must satisfy following condition A= surface area

If above condition is not satisfied than provide additional support by using chaplets.](https://image.slidesharecdn.com/u2p3corecoreprintsandchaplets-150422035805-conversion-gate02/85/U2-p3-core-core-prints-and-chaplets-29-320.jpg)